Surface measuring device and its measuring method and calibration method

A technology for surface measurement and correction methods, applied in measurement devices, optical devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following examples serve as illustrations of the present invention. However, the content provided in the examples is for illustrative purposes only, and the drawn drawings are for illustration purposes, and are not intended to limit the protection scope of the present invention. Furthermore, unnecessary elements are also omitted in the illustrations of the embodiments in order to clearly show the technical characteristics of the present invention.

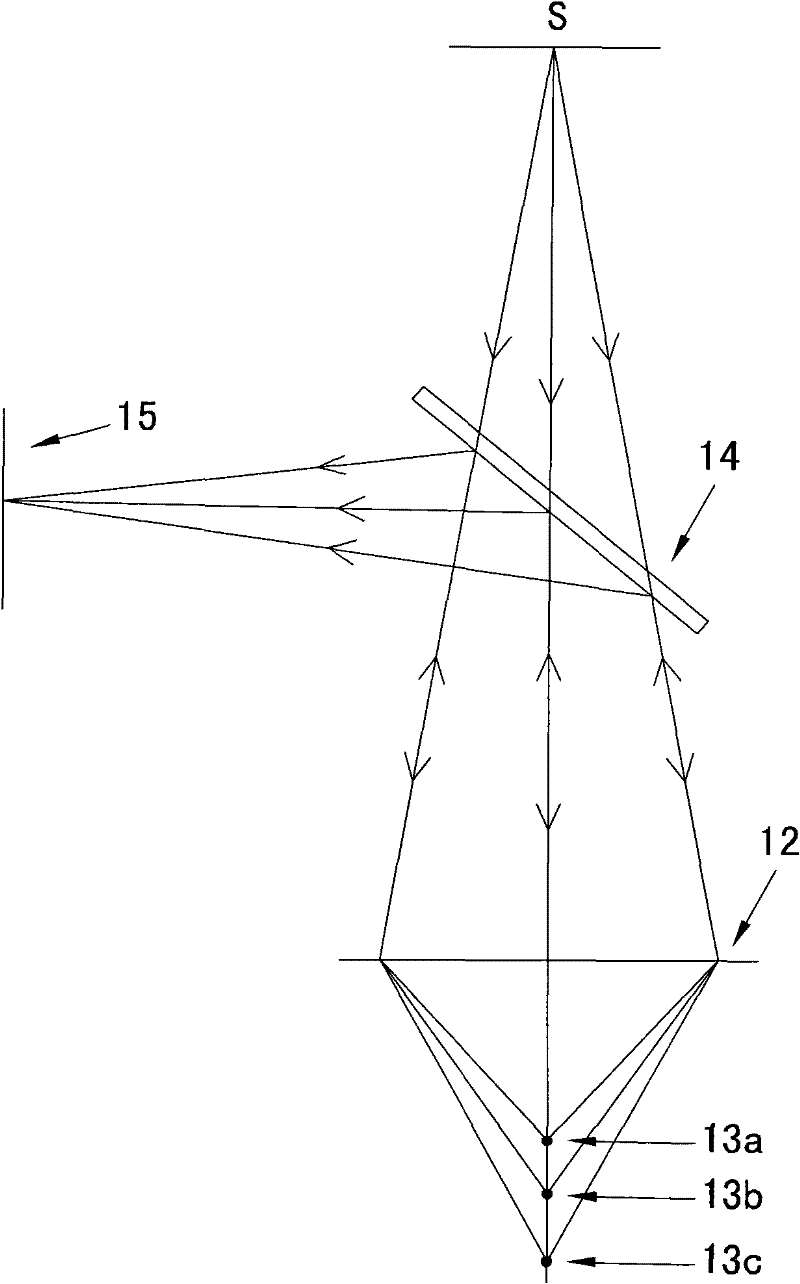

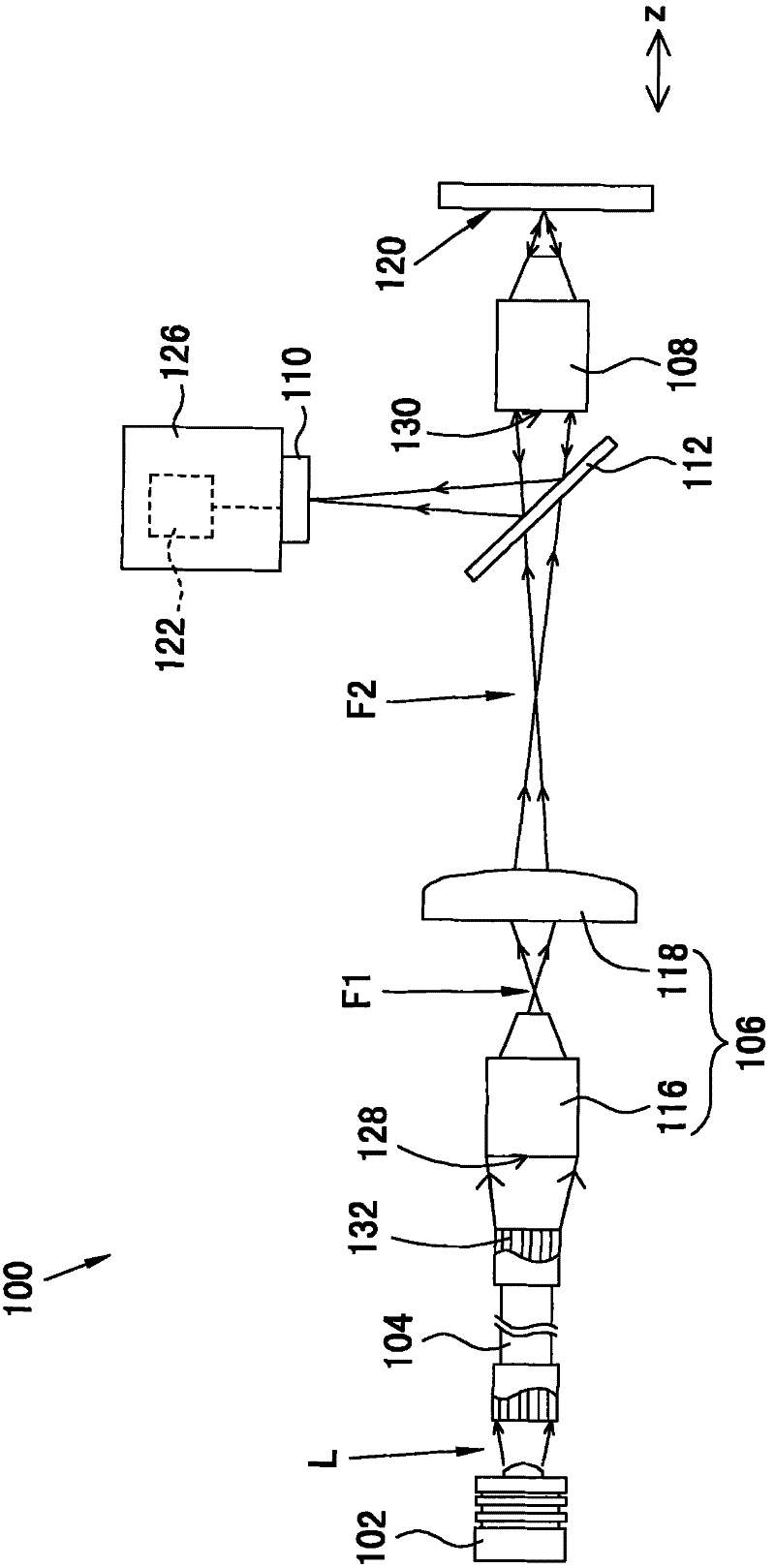

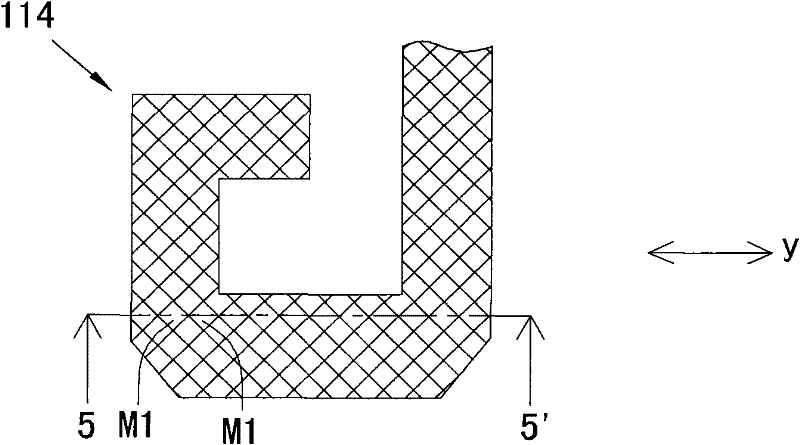

[0052] Please refer to figure 2 , which is a schematic diagram of a surface measuring device according to an embodiment of the present invention. The surface measuring device 100 is used to measure the surface to be measured 120, wherein the surface measuring device 100 includes a light source 102, a fiber optic tube 104, a first lens group 106, a second lens group 108, an image sensing unit 110, a spectroscopic A mirror 112 and a processing unit 122 . The first lens group 106 includes a third lens group 116 and a pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com