Leak testing device and method for battery case

A battery case and leak detection technology, which is used in liquid/vacuum measurement for liquid tightness, and by measuring the acceleration and deceleration rate of fluid, etc. Simple, short leak detection time, and the effect of ensuring the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

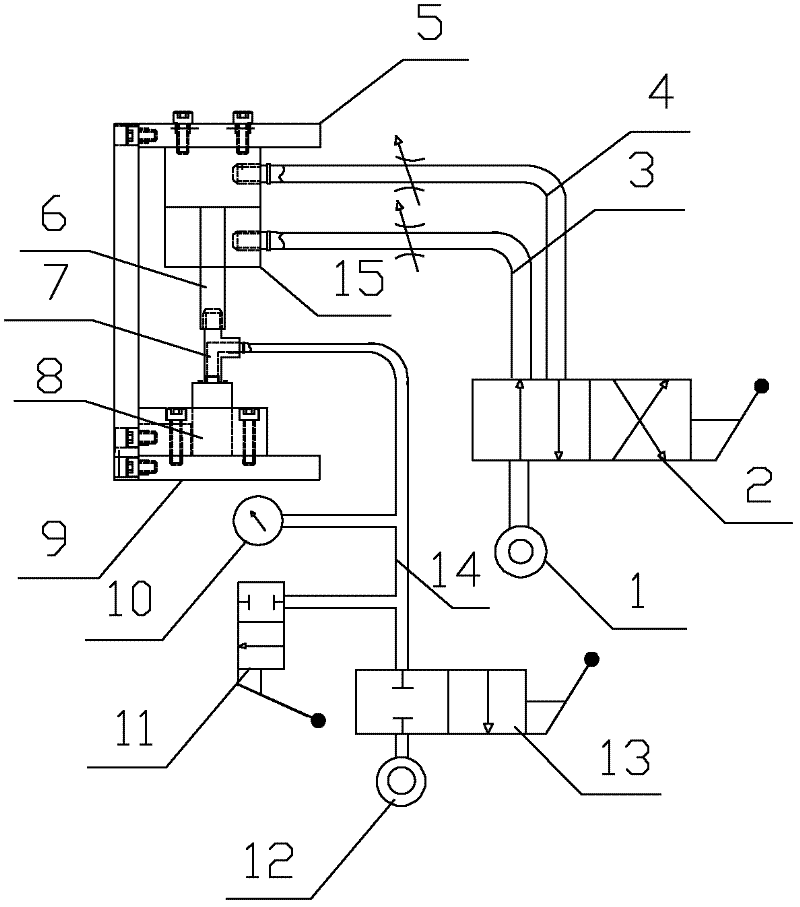

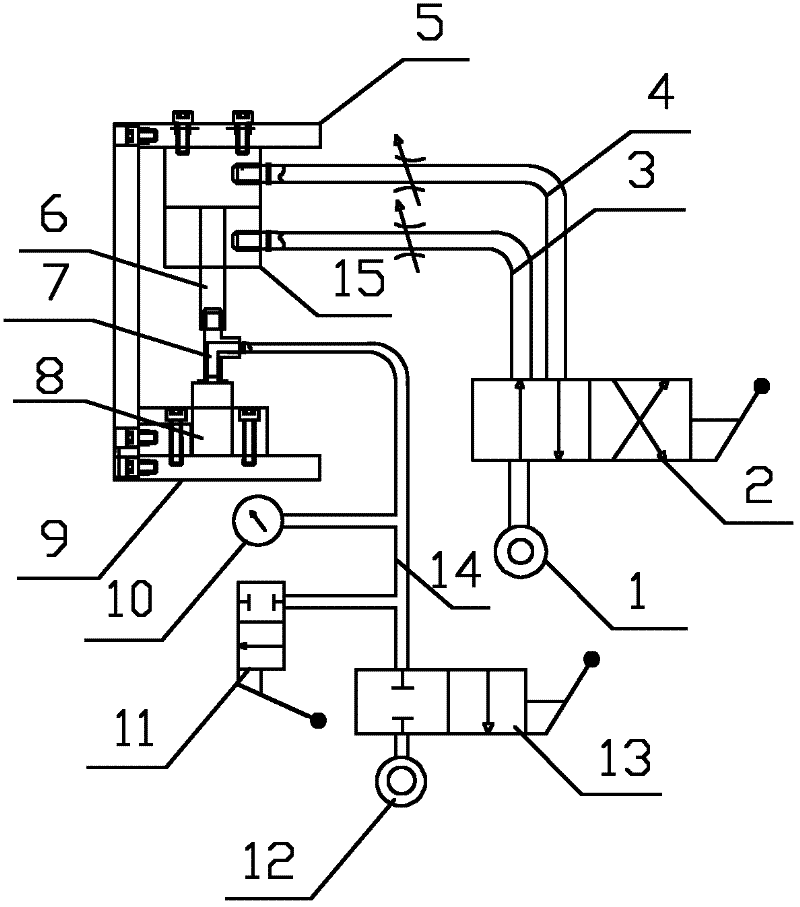

[0026] see figure 1 , the embodiment of the present invention provides a battery case leak detection device, including a plugging head 7 and a vacuum system. The plugging head 7 is connected with the liquid injection port of the battery casing to be tested, and the liquid injection port is isolated from the outside world. The pipeline 14 of the vacuum pumping system is connected with the plugging head 7, and the liquid injection port is connected with the plugging head. 7 is in communication with the vacuum pumping system, and a vacuum pressure gauge 10 is provided on the pipeline 14 .

[0027] In the battery case leak detection device provided by the embodiment of the present invention, the vacuum system is turned on during leak detection, and the battery case to be tested is vacuumed through the plugging head 7, and the battery case to be tested is maintained after vacuuming. Vacuum degree, the pressure change is observed through the vacuum pressure gauge. Due to the high s...

Embodiment 2

[0035] An embodiment of the present invention provides a method for measuring the leak of a battery case by using the battery case leak detection device provided in Embodiment 1. The method mainly includes the following steps:

[0036] see figure 1 , seal the liquid injection port of the battery casing to be tested with the plugging head 7;

[0037] Turn on the vacuum system to vacuumize the battery case to be tested;

[0038] When the vacuum gauge 10 shows that the negative pressure is 80-100, the vacuum pumping system is closed;

[0039] Keeping the vacuum in the battery case to be tested for 5-15 seconds;

[0040] Observe whether the reading of the vacuum pressure gauge 10 changes, and judge whether there is a leak. When observing, if the reading of the vacuum pressure gauge 10 drops, it means that gas enters the battery casing to be tested from the outside, that is, there is a leak in the battery casing to be tested, and if the reading remains unchanged, it means that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com