Vacuum Break Mechanism in Superconducting Feeder System

A superconducting feeder and superconducting busbar technology, which is applied in the direction of superconducting magnets/coils, nuclear reactors, nuclear power generation, etc., can solve problems such as difficult design, achieve the effect of optimizing temperature gradient, reducing thermal load, and meeting displacement requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

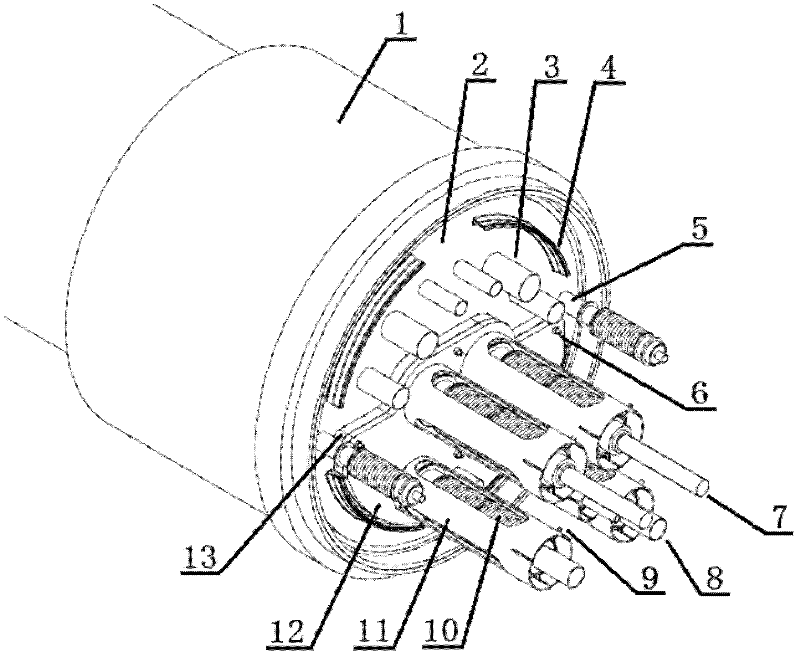

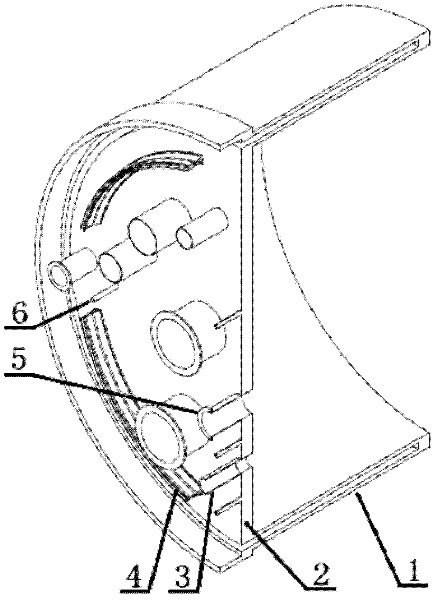

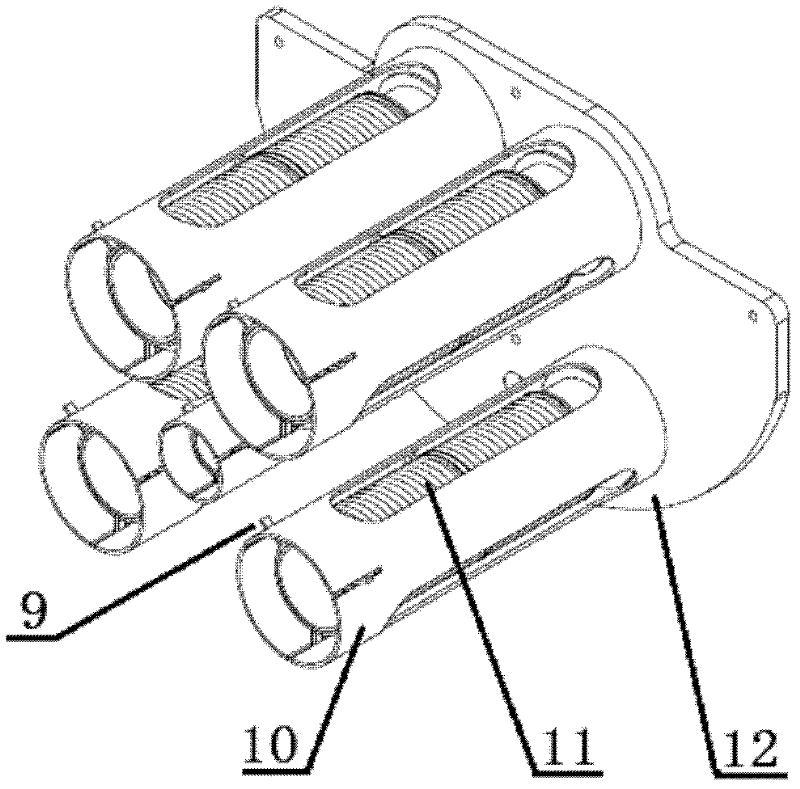

[0021] Referring to the accompanying drawings, the vacuum isolation mechanism in the superconducting feeder system includes a vacuum isolation main body, a superconducting busbar 7, a cryogenic pipeline 8, and a bellows 10. The central partition 2 is provided with a diagnostic line channel 3, and the vacuum isolation main body consists of a peripheral The U-shaped neck tube 1 and the central partition 2 are composed of an arc-shaped heat cut-off 4 at the edge of the central partition, and the bellows protective sleeve base 12 is fixed on the central partition 2, and the bellows protective sleeve base 12 An intermediate backing plate 2 is provided on the side section, and a plurality of bellows protective sleeves 11 are fixedly distributed on the base of the bellows protective sleeve. A bellows 10 is arranged inside the bellows protective sleeve, and a low-temperature pipeline 8 is arranged inside the bellows. There is a superconducting busbar 7 in the pipeline; a vertical guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com