Halogen-free flame retardants for epoxy resin systems

An epoxy resin system, epoxy resin technology, applied in the field of flame retardants, can solve the problems of inability to provide electricity, performance, processing and flame resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

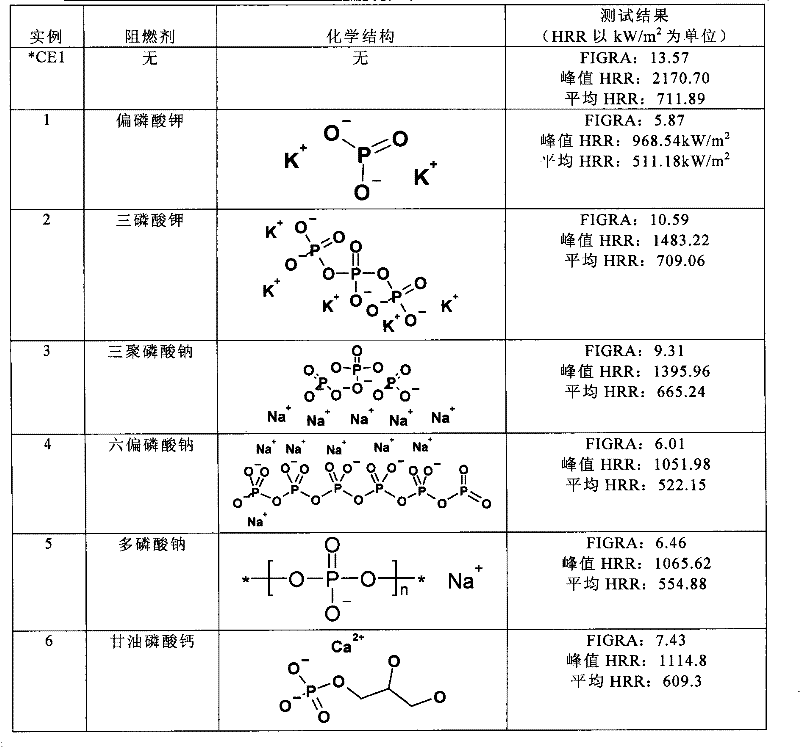

[0036] Sodium metaphosphate, potassium triphosphate, sodium hexametaphosphate, sodium polyphosphate, and calcium glycerophosphate were obtained from VWR International (West Chester, PA). Sodium tripolyphosphate, D-glucose-1-phosphate disodium salt hydrate, and D-glucose-1-phosphate dipotassium salt hydrate were obtained from Sigma Aldrich (Milwaukee, WI). Magnesium glycerophosphate and manganese glycerophosphate were obtained from Spectrum Chemicals (Gardena, CA). Scotchcast 4 is an epoxy resin system available from 3M Company (Saint Paul, MN).

[0037] The flame retardant fillers of Examples 1-10 were first mixed into Part B of Scotchcast 4 resin using a SPEEDMIXER DAC 150FVZ from Flack Tek Inc. (Landrum, S.C.) at 3000 rpm for 1 minute, and then also using a SPEEDMIXER DAC 150FVZ to Component A of Scotchcast 4 resin was mixed in at 3000 rpm for 1 minute. The total weight % of the flame retardant in the mixed resin was 15%. The weight ratio of component A / component B was 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com