Method for preparing hydroxyl ester

A technology for the synthesis of hydroxy esters and hydroxy esters, applied in the field of preparation of hydroxy esters, can solve the problems of high cost, low purity, low yield, etc., and achieve the effect of low cost and easy reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

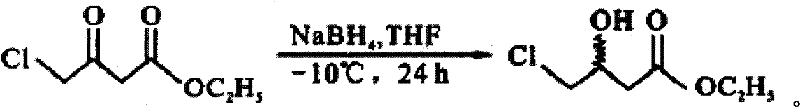

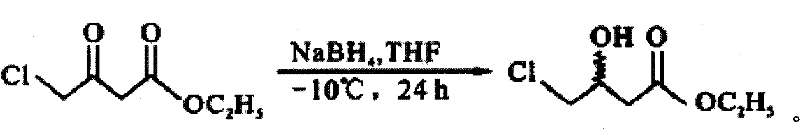

Image

Examples

Embodiment 1

[0016] (1), weigh 1.89g of sodium borohydride, add 120ml of absolute ethanol and 10ml of 1% sodium hydroxide solution to obtain 0.05mol of sodium borohydride solution;

[0017] (2), weigh 16.45 g of ethyl 4-chloroacetoacetate in a conical flask, add 30 ml of absolute ethanol to dissolve completely, and obtain 0.1 mol of ethyl 4-chloroacetoacetate solution;

[0018] (3) Add the sodium borohydride solution into a 250ml three-neck flask, add the ethyl 4-chloroacetoacetate solution dropwise into the sodium borohydride solution within 10 minutes through the dropping funnel, and place it in an ice-water bath at 0-3°C After reacting for 2 hours, use pure ethanol to neutralize to acidity, and stir to complete the reaction;

[0019] (4), filter the reaction solution to remove salt, then concentrate under reduced pressure to get ethanol, then salt out with saturated brine, separate the oil layer, and put it into another clean three-necked flask;

[0020] (5), extract the water layer wi...

Embodiment 2

[0023] (1), weigh 3.28g of sodium borohydride, add 180ml of absolute ethanol and 20ml of 1% sodium hydroxide solution to obtain 0.12mol of sodium borohydride solution;

[0024] (2), weigh 25.21 g of ethyl 4-chloroacetoacetate with a conical flask, add 40 ml of absolute ethanol to dissolve completely, and obtain 0.25mol of ethyl 4-chloroacetoacetate solution;

[0025] (3) Add the sodium borohydride solution into a 250ml three-neck flask, add the ethyl 4-chloroacetoacetate solution dropwise into the sodium borohydride solution within 20 minutes through the dropping funnel, and place it in an ice-water bath at 0-3°C After reacting for 5 hours, use pure ethanol to neutralize to acidity, and stir to complete the reaction;

[0026] (4), filter the reaction solution to remove salt, then concentrate under reduced pressure to get ethanol, then salt out with saturated brine, separate the oil layer, and put it into another clean three-necked flask;

[0027] (5), extract the water layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com