Four-gear transmission mechanism and installation method thereof

A technology of transmission mechanism and assembly method, applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problems of aggravating gear wear, affecting the service life of gears, impact, etc., to prevent impact and noise, improve use longevity, wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

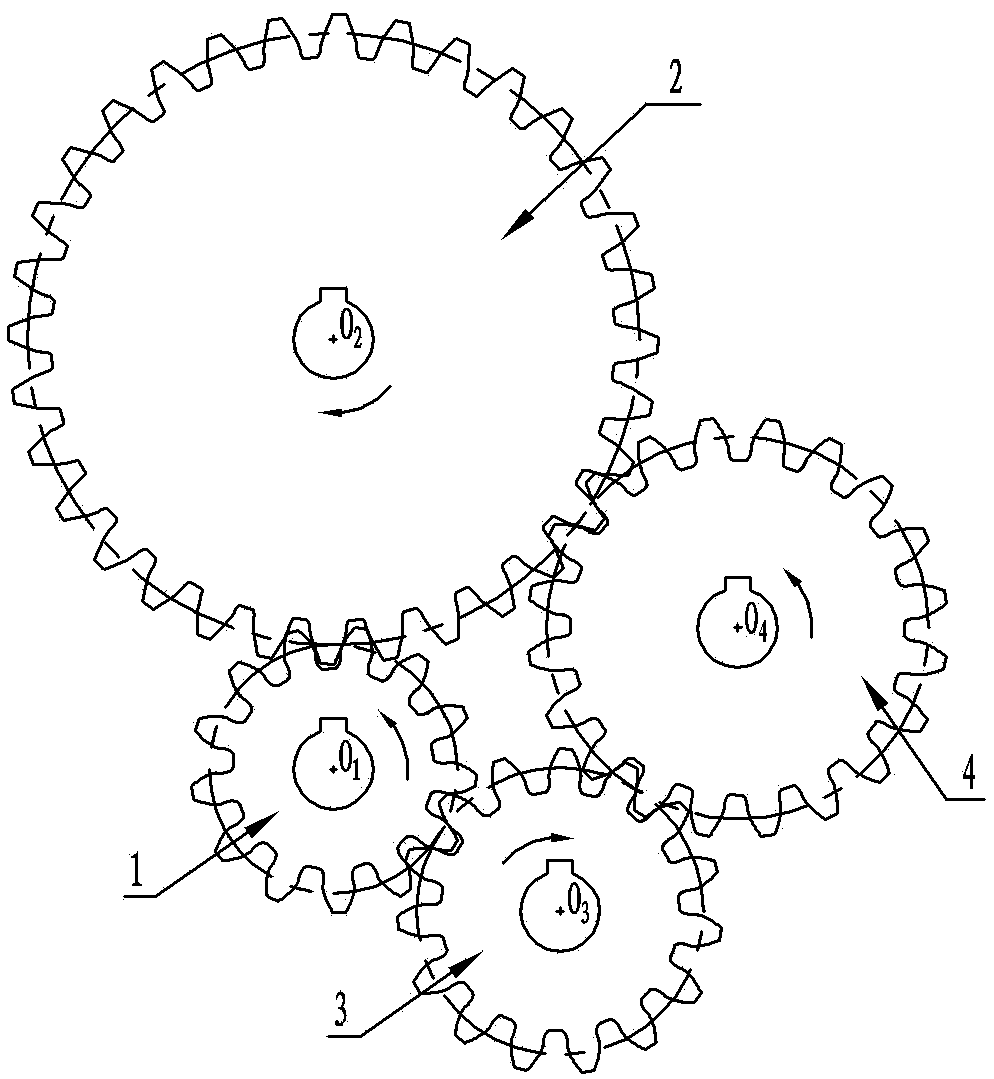

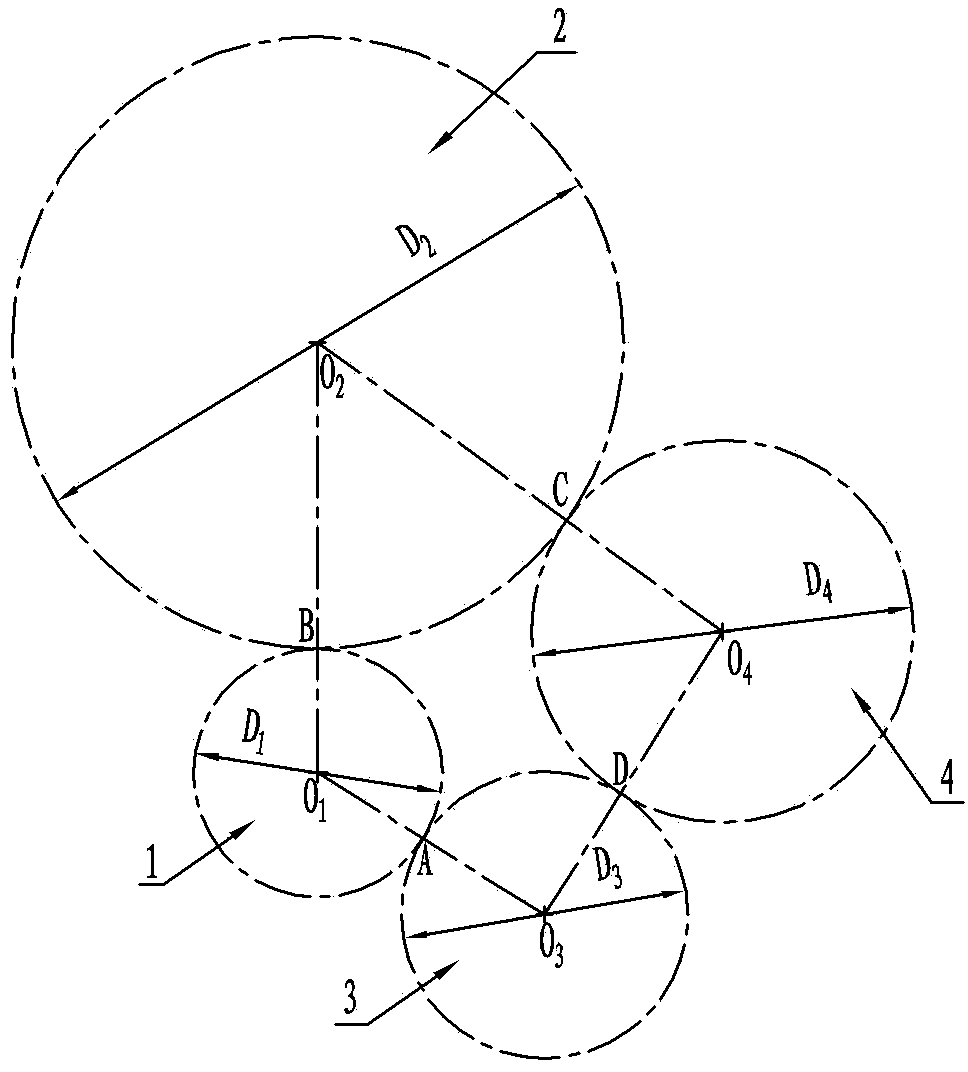

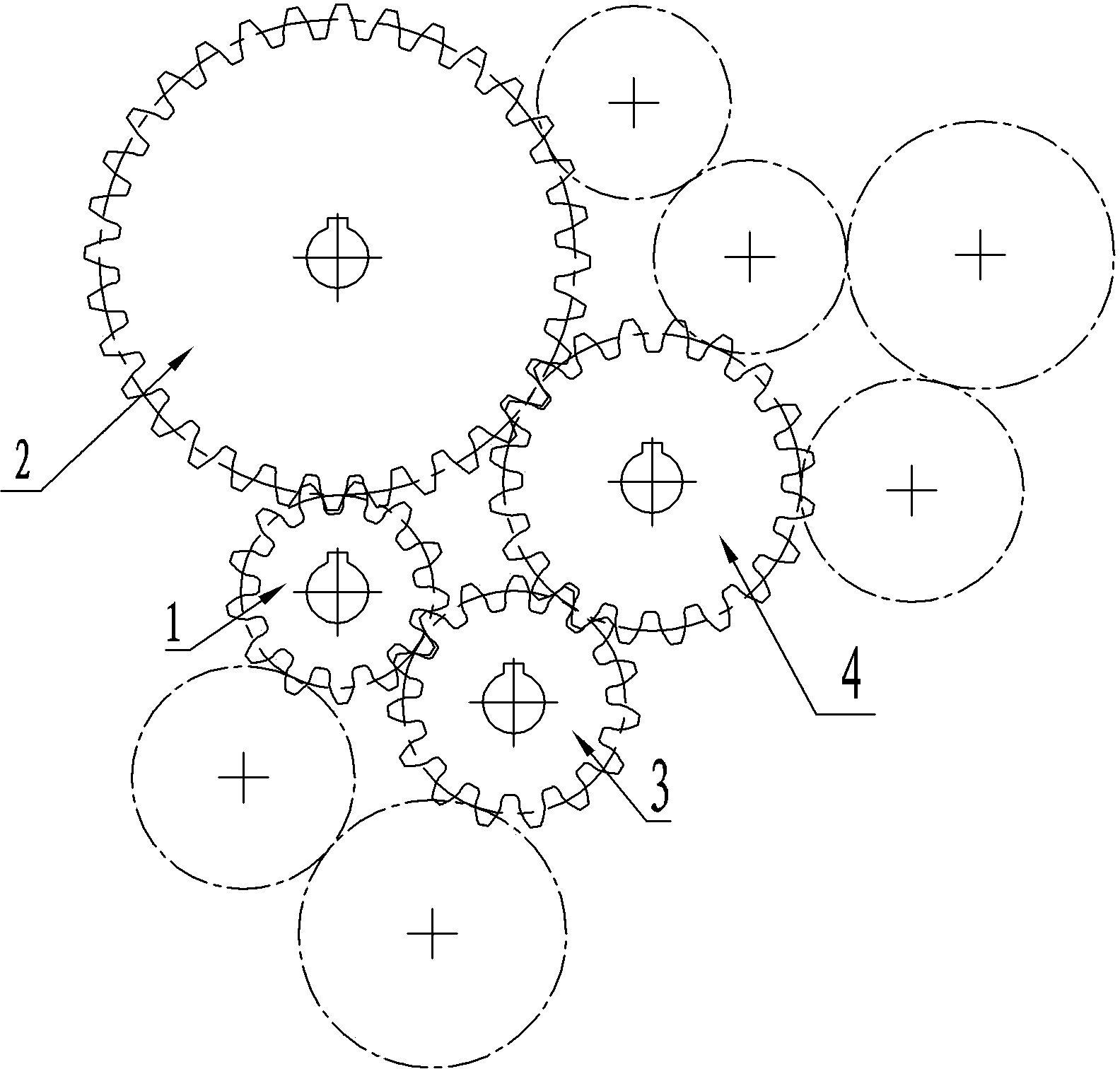

[0014] like figure 1 , figure 2 As shown in the figure, a four-gear transmission mechanism according to the present invention includes four gears 1, 2, 3, and 4 arranged together. The sizes of the four gears 1, 2, 3, and 4 can be selected according to actual needs. The index circles of the adjacent gears are tangent, and the center positions of the index circles of the four gears 1, 2, 3, and 4 are based on the formula To determine and arrange, among which, the four points A, B, C, D are the tangent points between the index circles of adjacent gears; for ∠AO 1 The arc length of the arc segment where B is less than 180°; for ∠BO 2 The arc length of the arc segment where C is greater than 180°; for ∠CO 4 The arc length of the arc segment where D is less than 180°; for ∠AO 3 The arc length of the arc segment where D is less than 180°; is the gear modulus, which is the standard value, It is the pitch of the gears, and the pitches of the four gears 1, 2, 3, and 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com