Tri-mixed gas (fuel, oxygen and air) lamp cap

A lamp holder and lamp wick technology, which is applied to gas fuel burners, combustion methods, combustion types, etc., can solve the problems of tube bottle waste, safety hazards, easy to be blown out and extinguished, etc., to ensure quality, eliminate safety hazards, and save money. effect of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

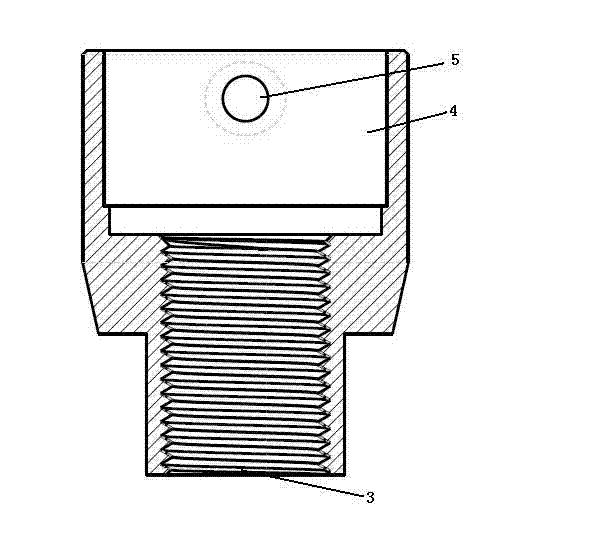

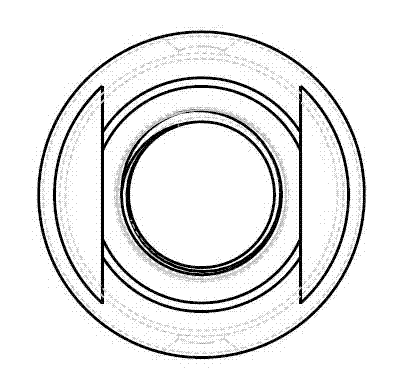

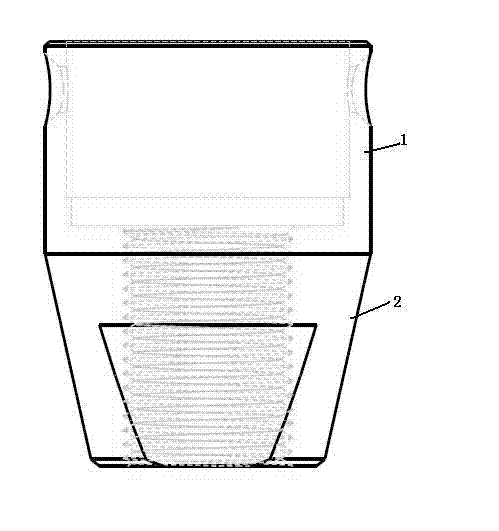

[0022] A three-gas hybrid lamp cap, which is composed of a lamp shell and a wick. The shape of the lamp shell is a superposition of cylindrical part 1 and round table part 2, such as figure 1 As shown, the truncated part 2 is 13mm high, the large bottom diameter is 23mm, and the small ground diameter is 17mm. There is a through and threaded round hole 3 with a diameter of 10mmd, which can be connected to the air supply pipe. The cylindrical part 1 has a diameter of 23mm. It is 27mm high and has a circular groove 4 opening at the front end of the lamp cap. The diameter of the circular groove 4 is 20mm, which matches the diameter of the wick, so that the wick can be seated in the circular groove 4. The bottom of the circular groove 4 has an inwardly shrinking step, so There is a space of 2.5mm between the wick and the bottom of the circular groove 4, so that the incoming mixed gas can flow freely. There are two symmetrical, penetrating, and threaded round holes with a diameter of 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com