Constant-temperature cold water unit and control method thereof

A chiller and refrigerating unit technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of single PID control mode unstable effect, large electromagnetic interference, damage, etc., to achieve perfect self-adaptive performance and ensure water temperature The effect of constant and stable precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

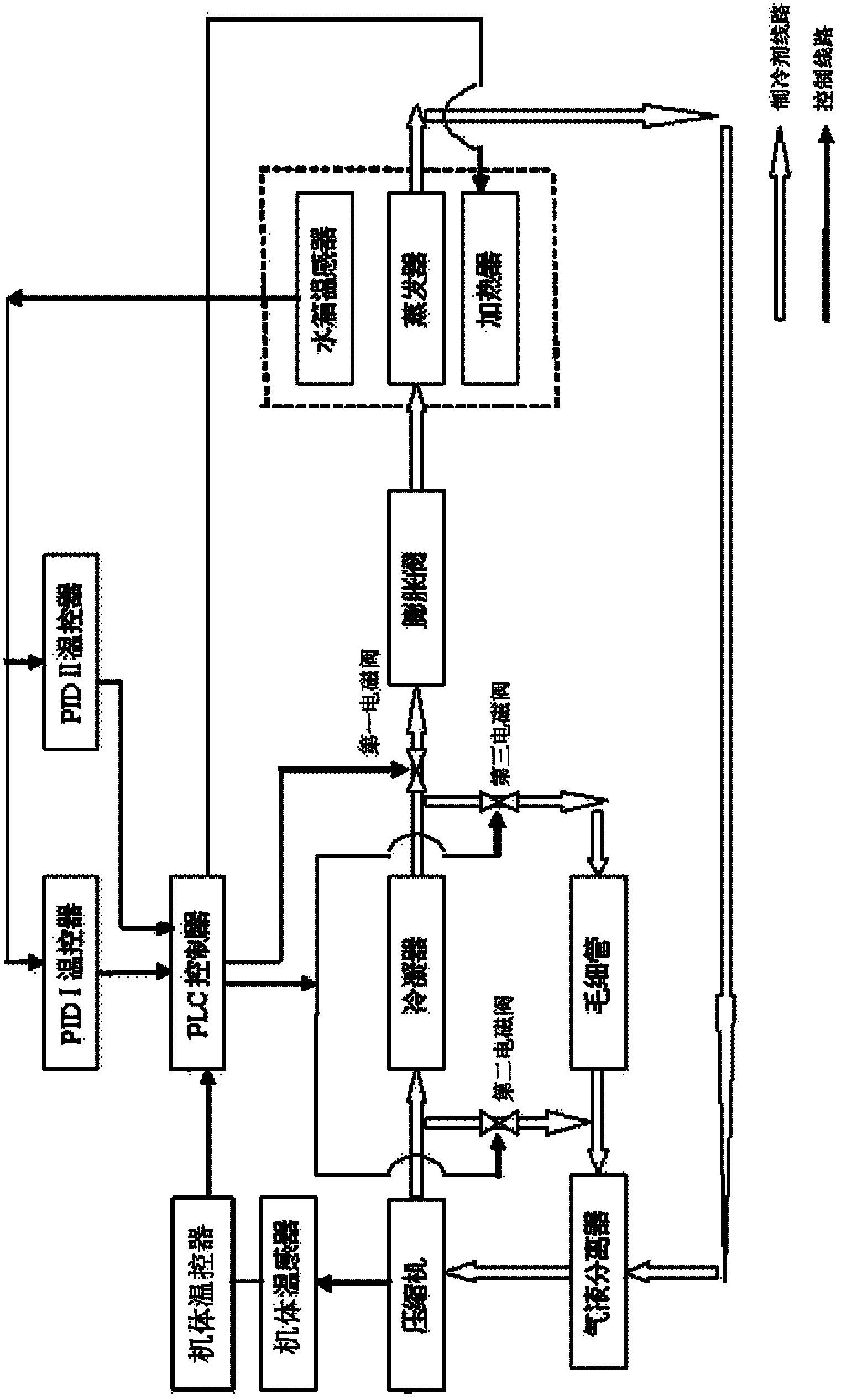

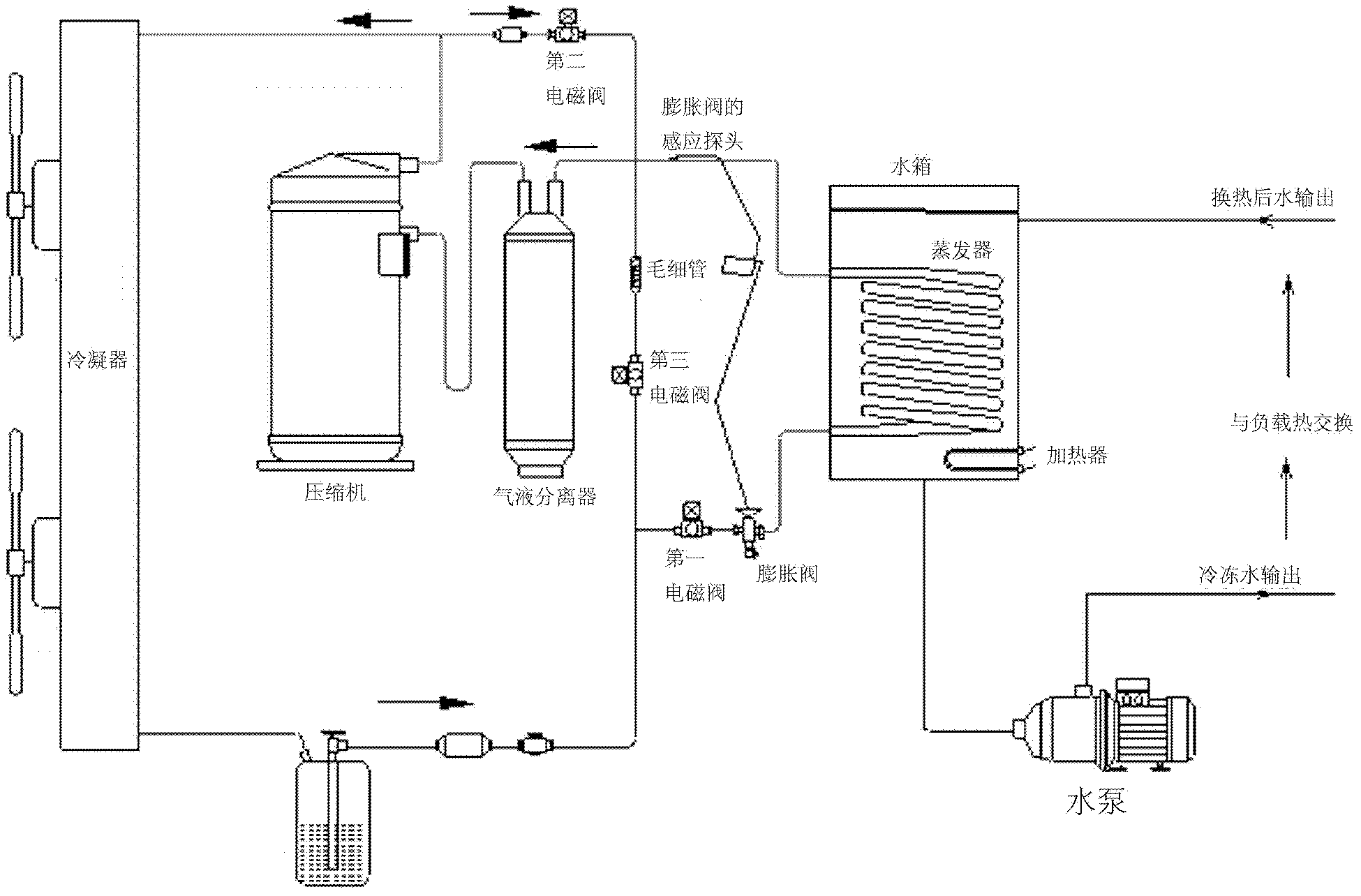

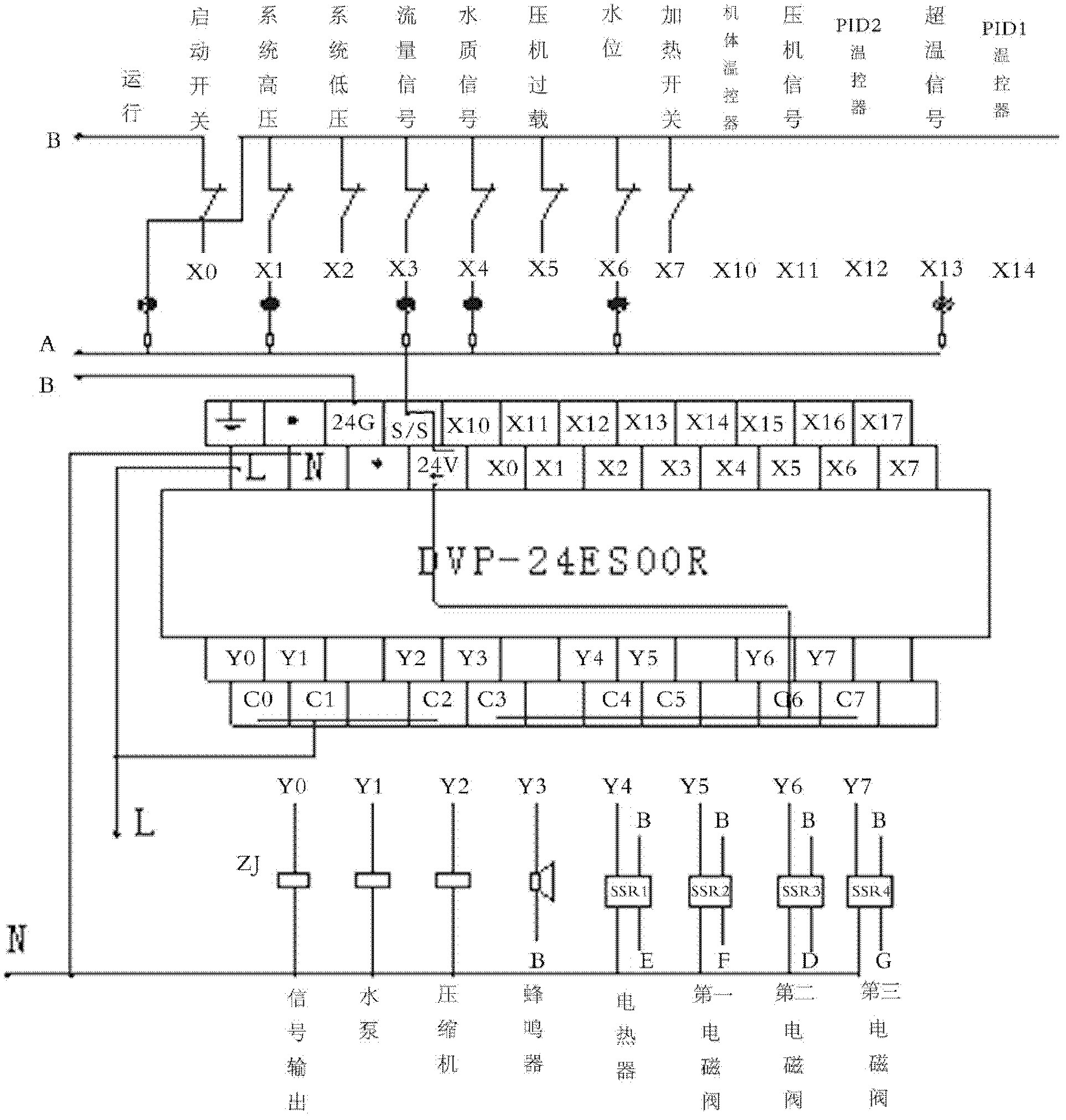

[0029] In this embodiment, the Copeland scroll compressor is selected, with a cooling capacity of 20,000W and a water tank of 120L. Delta DVP-PLC programmable controller and dual Omron digital thermostats are used to realize dual PID control through its self-tuning mode. figure 1 It is a system block diagram of an embodiment of the present invention, figure 2 It is a technical diagram of the refrigeration system, including a water tank, a refrigeration unit, a controller, a water tank temperature sensor, and a water tank thermostat. The refrigeration unit is sequentially composed of a compressor, a condenser, an expansion valve, and an evaporator to form a closed water tank refrigeration circuit. The evaporator and the water tank temperature sensor are arranged in the water tank, and the signal output by the water tank temperature sensor is input to the controller through the water tank temperature controller.

[0030] The refrigeration unit also includes a first solenoid val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com