Converter afterheat and steam compensation combustion type generating system

A waste heat steam and power generation system technology, applied in steam engine installations, furnaces, waste heat treatment, etc., can solve problems such as large steam consumption, turbine shutdown, safety generation of turbine generators and impact on power generation benefits, etc., to improve power generation efficiency. , the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

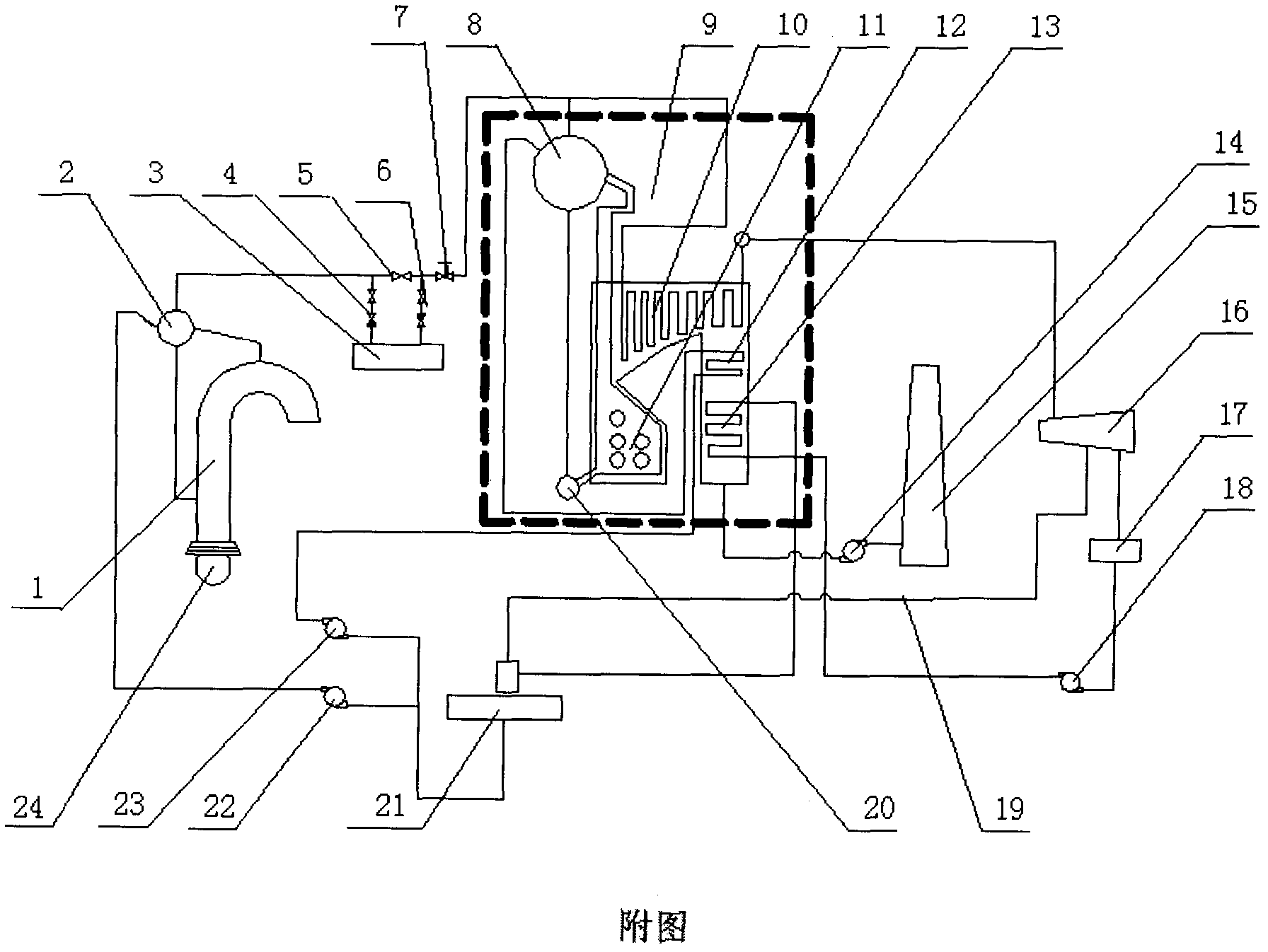

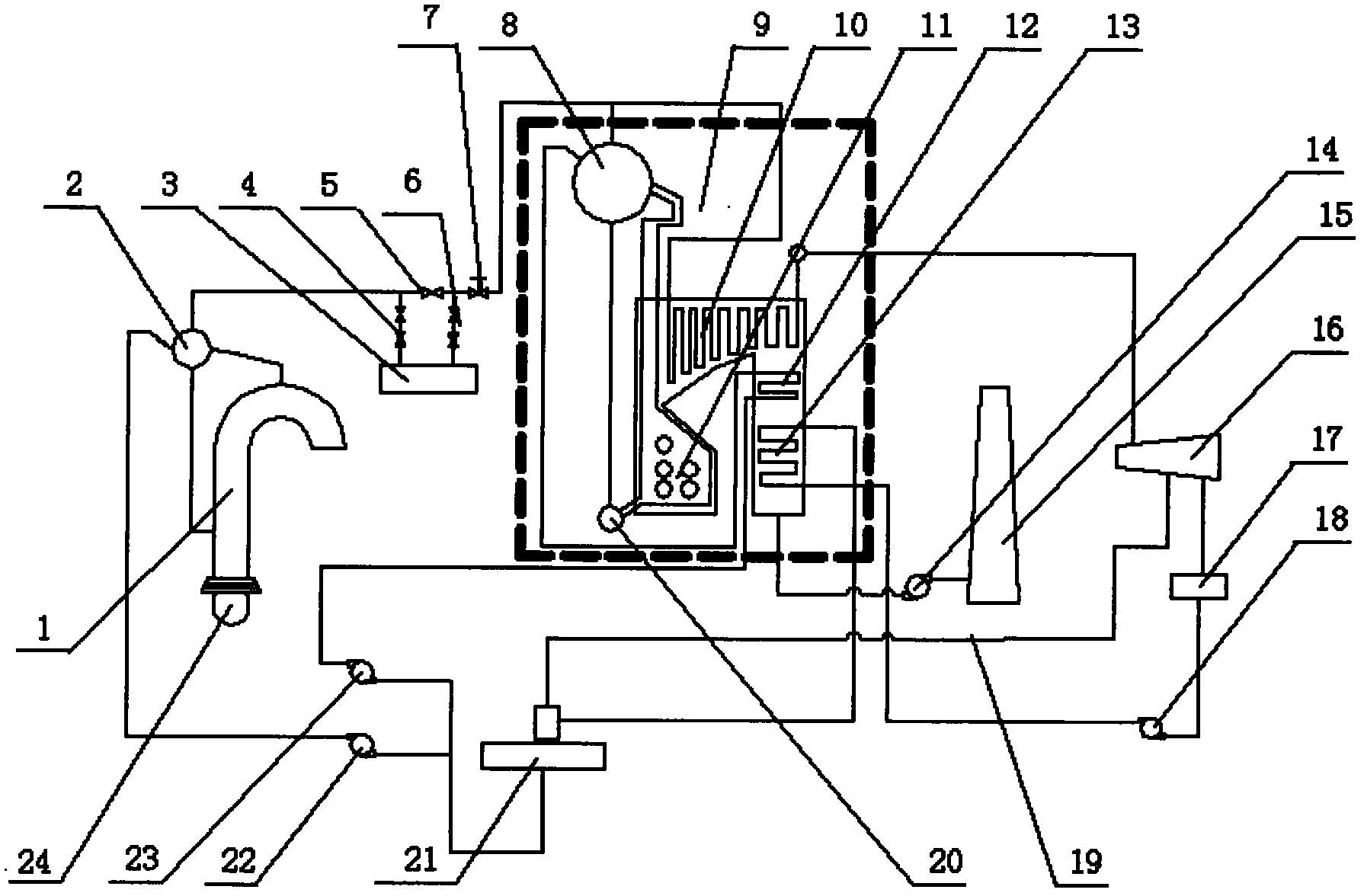

[0021] Embodiment: As shown in the accompanying drawings, a converter waste heat steam supplementary combustion power generation system, which includes a converter vaporization flue (1), a converter steam drum (2), a heat accumulator (3), a steam turbine generator set (16 ), the steam outlet of the converter steam drum (2) is connected with the steam inlet of the heat accumulator (3) and the steam outlet of the heat accumulator (3) through pipelines, and it is characterized in that: the steam outlet of the heat accumulator (3) A post-combustion boiler (9) is provided on the steam pipeline between the port and the steam inlet of the steam turbine generator set (16), and a superheater (10) and a steam drum (8) are provided inside the post-combustion boiler (9). The steam outlet of the heater (3) is connected to the steam outlet of the steam drum (8) of the supplementary combustion boiler (9) through a pipeline, and the steam outlet of the steam drum (8) of the supplementary combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com