Method for adjusting power of auxiliary electric boiler of nuclear power plant

A power regulation and auxiliary power technology, which is applied in the fields of nuclear power plant auxiliary equipment, factory parameter adjustment, nuclear power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

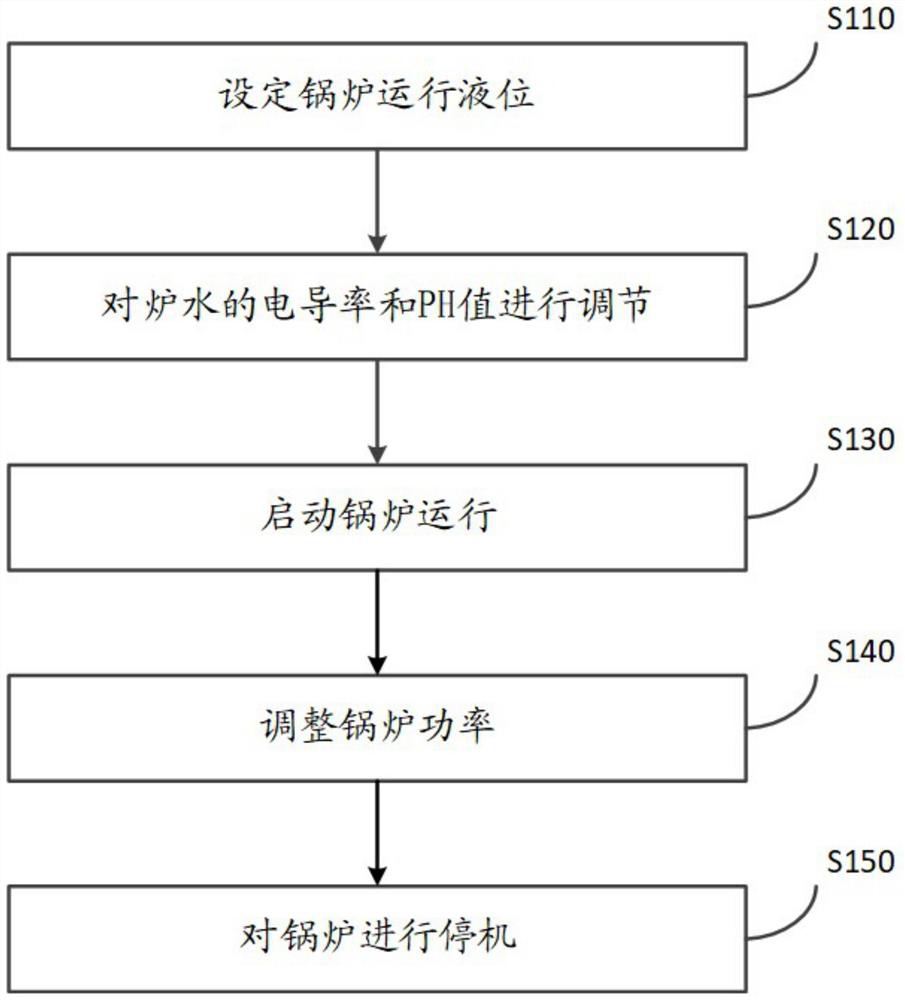

[0030] A method for regulating power of an auxiliary electric boiler in a nuclear power plant, comprising the following steps:

[0031] (1) The boiler is supplied with water to the set operating liquid level of 1500mm, and when the low liquid level is set to 1400mm, the replenishment pump is started in chain to replenish water, and when the operating liquid level is reached to 1500mm, the replenishment pump is stopped in chain; when the high liquid level is set to 1600mm, the boiler sewage is started in chain The valve is discharged, and when the operating liquid level reaches 1500mm, the boiler blowdown valve is closed in chain.

[0032] (2) Start the first boiler water dosing pump, add a conductivity regulator to the boiler, and adjust the conductivity to a range of 20-30 μS / cm; start the second boiler water dosing pump, and add a boiler water pH regulator to the boiler , so that the pH value of the furnace water is in the range of 9.5 to 10.0.

[0033] (3) Start the boiler...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com