Dish-type solar thermal and natural gas combined power generation system

A technology of combined power generation and solar energy, which is applied in solar thermal power generation, solar thermal devices, steam generation, etc., can solve the problems of discontinuous energy utilization, expensive equipment and materials, and difficult implementation, and reduce the working medium and heat of start-up and shutdown Low loss, low power consumption, and reduced input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

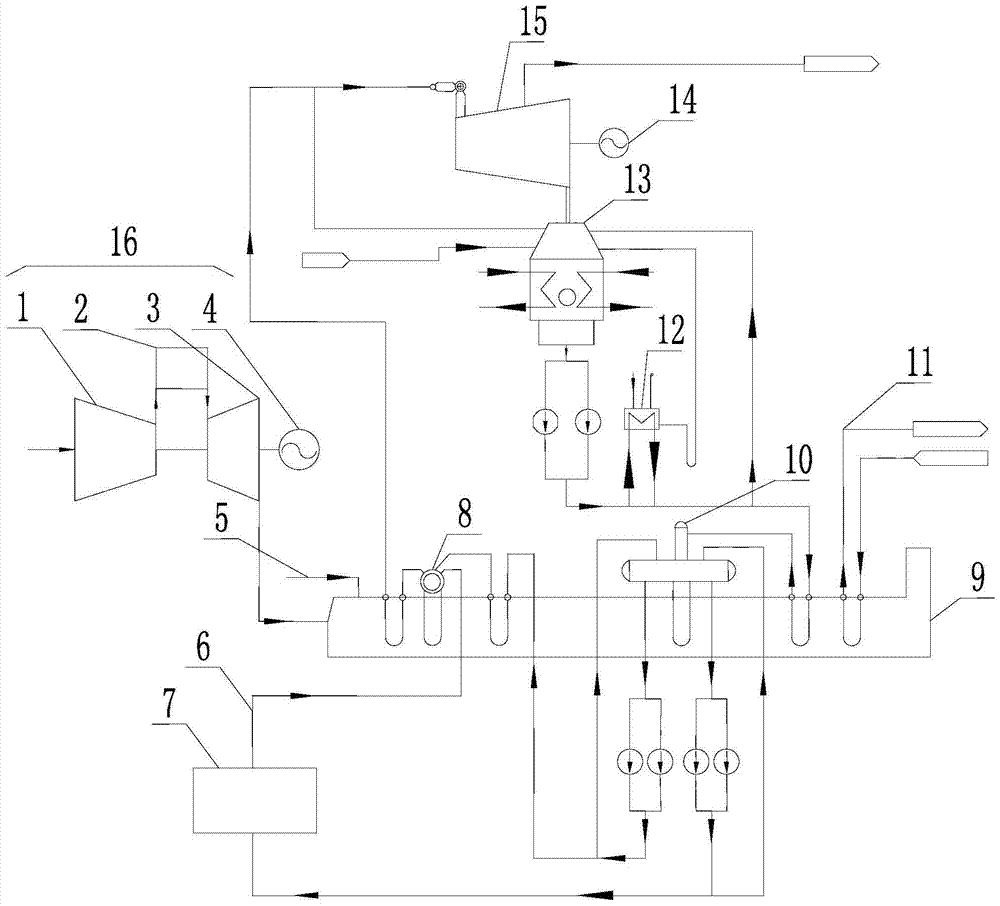

[0024] Embodiment 1 of the present invention: as figure 1 As shown, a dish-type solar-thermal and natural gas combined power generation system includes a gas-fired power generation system 16, a waste heat boiler 9, a dish-type solar-thermal conversion system 7, a steam turbine 15 and a second generator 14; the steam turbine 15 and the second power generator The gas-fired power generation system 16 is connected with the flue gas system of the waste heat boiler 9, the steam-water system of the steam turbine 15 is connected with the steam-water system of the waste heat boiler 9, and the dish solar light-to-heat conversion system 7 is connected to the steam-water circulation channel 6 and the steam turbine 15. connected. The gas power generation system 16 includes an air compressor 1 , a combustion chamber 2 , a gas turbine 3 and a first generator 4 . The air compressor 1, the combustion chamber 2 and the gas turbine 3 are connected in sequence, the gas turbine 3 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com