Insulated gate bipolar transistor with floating buried layer

A bipolar transistor, insulated gate technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as difficulty in meeting the requirements of high-speed IGBT devices, low forward voltage drop, slow turn-off speed, etc. The effect of reverse safe working area, reducing forward voltage drop, and reducing turn-off time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

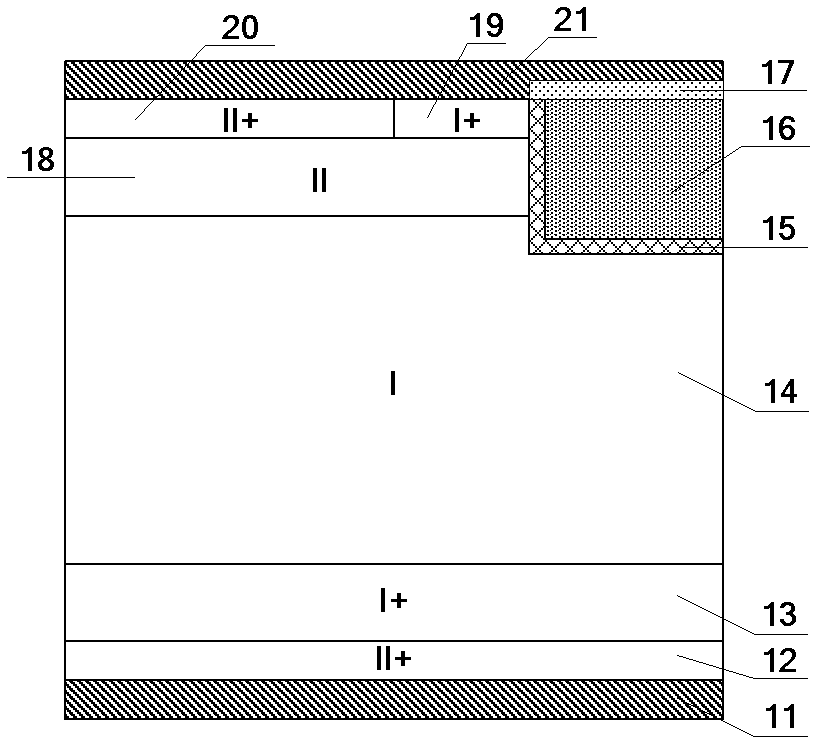

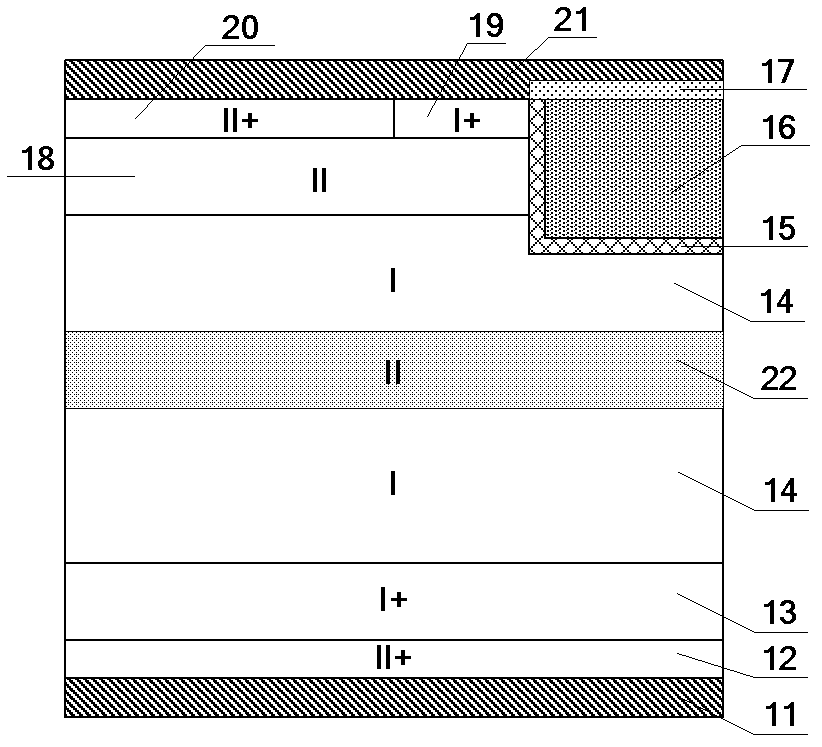

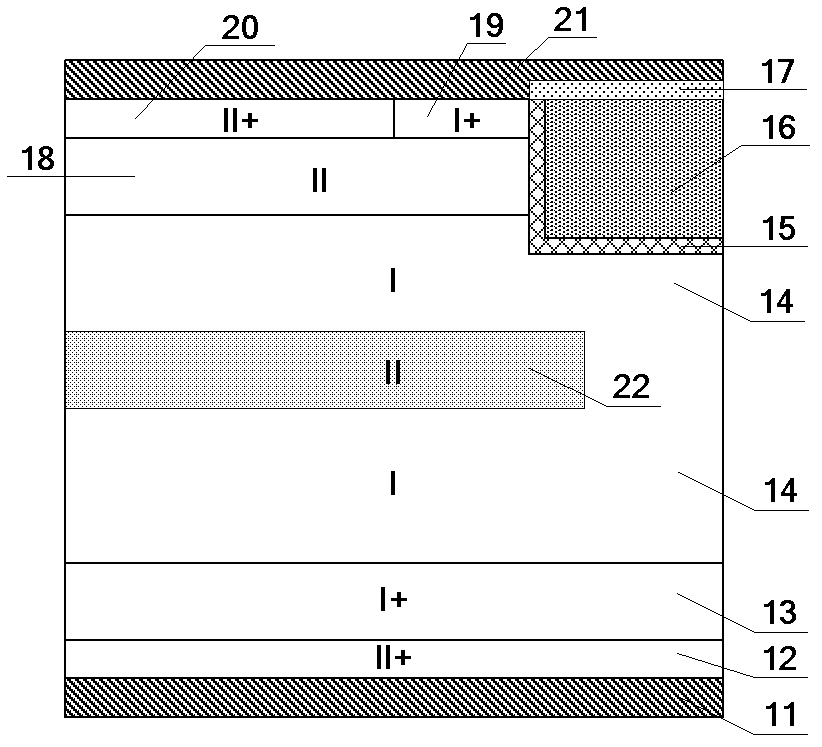

[0022] An insulated gate bipolar transistor with a floating buried layer, such as Figure 2 to Figure 7 As shown, there are one or more layers of continuous or discontinuous buried layers 21 of the second conductivity type in the drift region 14 of the first conductivity type of the IGBT.

[0023] In the above embodiment:

[0024] The buried layer 22 of the second conductivity type can be obtained through a two-step diffusion process on the substrate material of the first conductivity type before the traditional IGBT process starts. That is, before the start of the traditional IGBT process, a step-deep diffusion of impurities of the second conductivity type is performed on the substrate material of the first conductivity type, and then a shallow step of diffusion of impurities of the first conductivity type is performed to control the junction depth between the two diffusions. If it is poor, the buried layer 22 of the second conductivity type meeting the thickness and concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com