Power thermocouple conversion element with long-range concentrated cooling mode

A technology of conversion elements and thermocouples, which is applied to thermoelectric device parts, thermoelectric devices that only use the Peltier or Seebeck effect, etc., can solve the problem of low output power of thermocouple conversion elements, large use of semiconductor thermoelectric materials, and insufficient energy Using problems such as reducing the influence of the Peltier effect, reducing the generation of Joule heat, and reducing the length of the arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

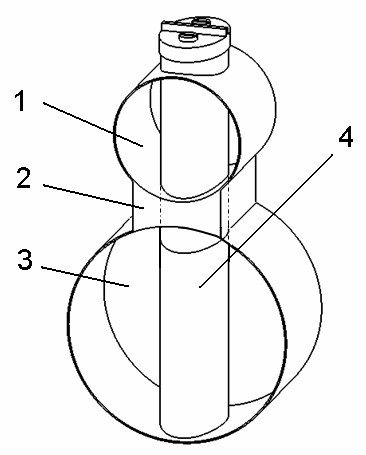

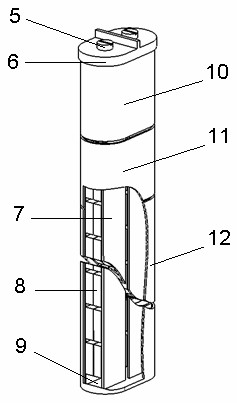

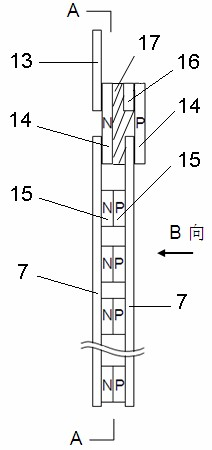

[0040] Such as figure 1 As shown, the thermocouple conversion element 4 of the present invention (the cross section is in-line shape) is arranged in the cold source channel 1, the heat insulation layer 2, and the heat source channel 3. If the heat source channel 3 is axially extended, the thermocouple conversion element 4 will be Axial extension. Corresponding to the set position, the thermocouple conversion element 4 is divided into three sections along the longitudinal direction: (1) The high-temperature section of the thermocouple conversion element 4 is set in the heat source channel 3, and the thermal fluid flowing in the channel is a high-temperature heat source, And the temperature is uniform, the high temperature section of the thermocouple conversion element 4 performs convective heat exchange and radiation heat exchange with the hot fluid to obtain the maximum heat energy; (2) The heat source channel 3 and the cold source channel 1 are separated by the heat insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com