Packaging technology of IPMC (ionic polymer metal composite) driver

A packaging process and driver technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc. The problem of poor bonding force with the IPMC driver can ensure the sealing performance, eliminate the relaxation effect, and achieve the effect of tight bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, the present invention will be described in further detail by taking the strip-shaped IPMC driver (40mm×5mm) as an example.

[0024] A packaging process for an IPMC driver, comprising the steps of:

[0025] (1) Make the IPMC driver and connect the lead electrodes

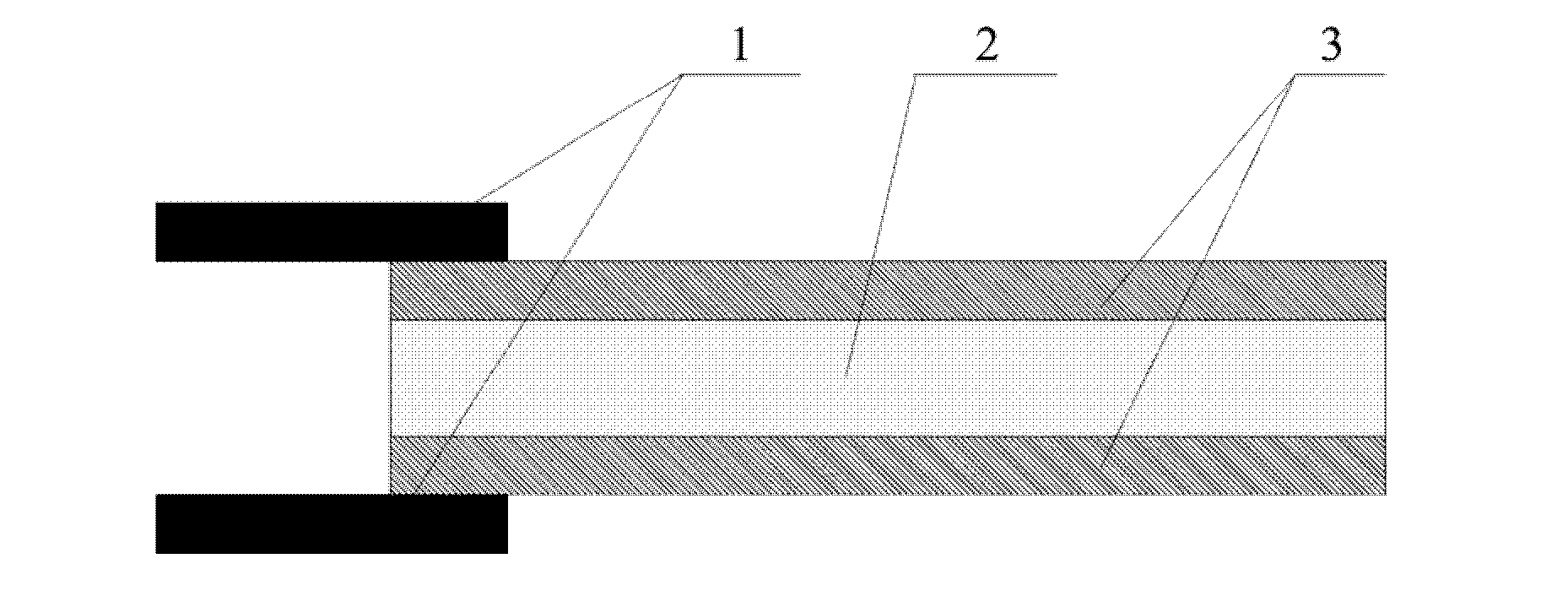

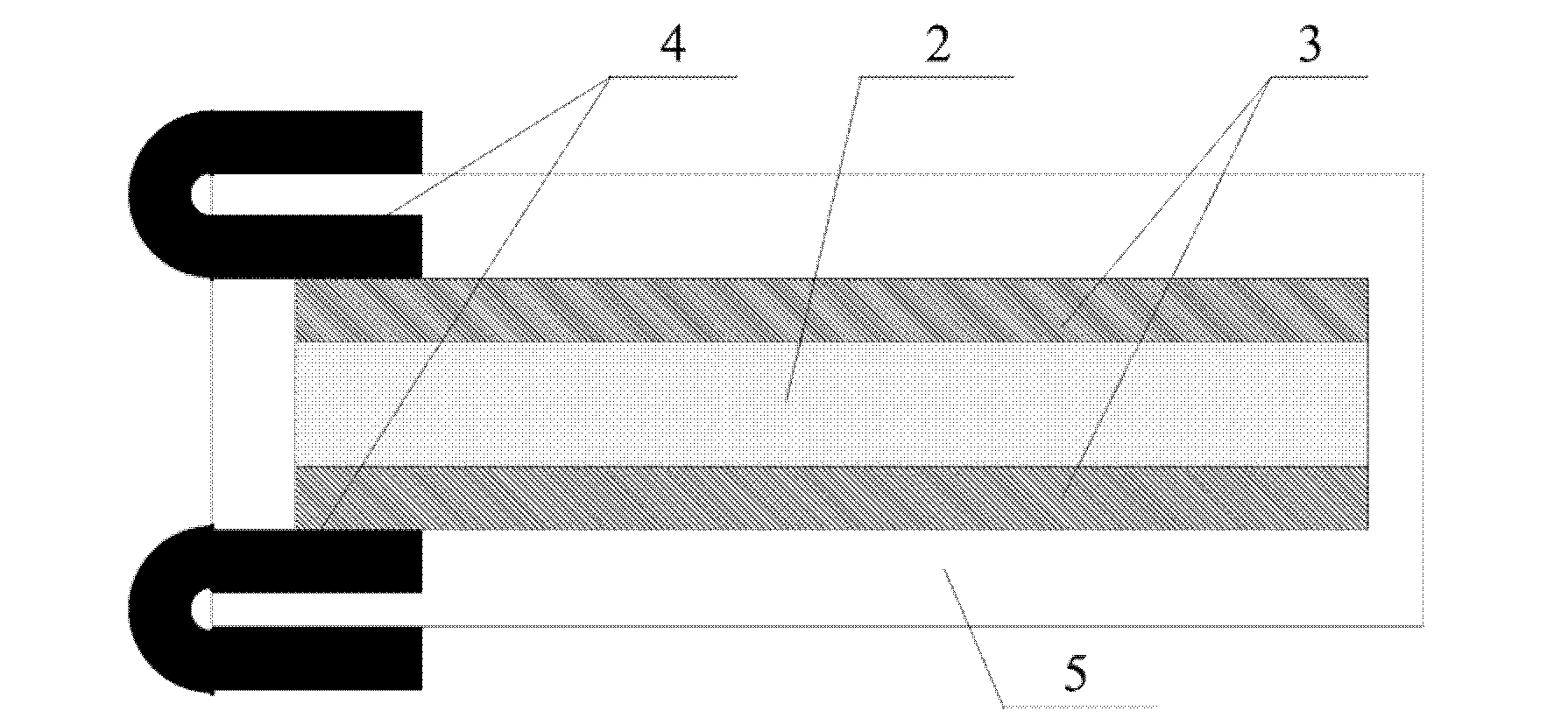

[0026] Connect upper and lower surface electrodes 3 respectively on the upper and lower surfaces of the IPMC core layer 2 to form an IPMC driver; make two initial lead-out electrodes 1, one of which is bonded to the edge of the upper surface electrode at one end of the IPMC driver, and the other is bonded to the IPMC driver. The edge bonding of the electrode on the lower surface of the terminal ( figure 1 ), and then the IPMC driver with the initial lead-out electrode 1 is put into deionized water as a whole to soak and fully absorb water;

[0027] The initial lead-out electrode 1 is cut into a 10mm×5mm electrode sheet with a conductive copper foil, and can also be cut into the same shape and size wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com