Air supply system for zinc-air power battery pack

A power battery pack and gas supply system technology, which is applied to hybrid battery components, fuel cell half-cells and primary battery-type half-cells, etc., can solve the problem of zinc-air battery's normal start-up performance and ensure normal operation. enabled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

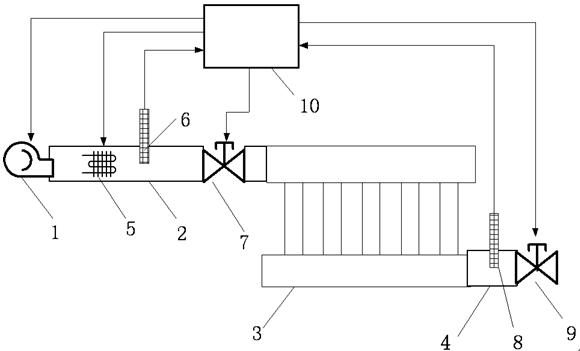

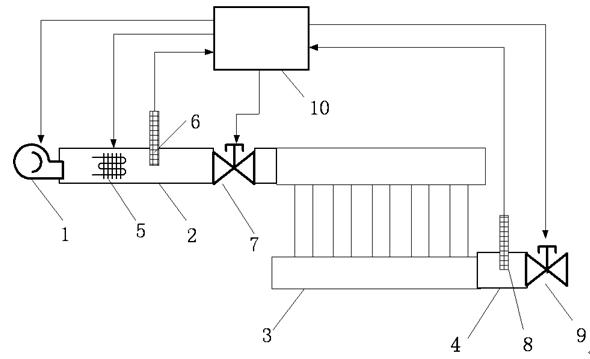

[0020] Such as figure 1 As shown, the gas supply system for zinc-air power battery packs includes a fan 1, an air intake pipe 2, a zinc-air power battery pack 3, and an air outlet pipe 4 connected in sequence, and also includes a heater 5, a first temperature sensor 6, a first normal closed solenoid valve 7, a second temperature sensor 8, a second normally closed solenoid valve 9 and a controller 10, the heater 5 is arranged on the air intake pipe 2 near the end of the fan 1, the first A normally closed solenoid valve 7 is arranged on the air intake pipe 2 near the end of the zinc-air power battery pack 3, and the first temperature sensor 6 is arranged between the fan 1 and the first normally closed solenoid valve 7 On the inlet pipe 2, the second normally closed solenoid valve 9 is arranged on the outlet pipe 4 close to the end of the zinc-air battery pack 3, and the second temperature sensor 8 is arranged on the On the outlet pipeline 4 between the zinc-air power battery pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com