Sulfenyl anode of lithium-sulfur rechargeable battery and preparation method thereof

A lithium-sulfur battery, sulfur-based technology, applied in the direction of secondary batteries, electrode manufacturing, active material electrodes, etc., can solve the problems of unsatisfactory electrode cycle stability, achieve good cycle stability, improve cycle performance, and prevent electrode self-discharge The effect of discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of sulfur-based composite active materials for secondary lithium-sulfur batteries:

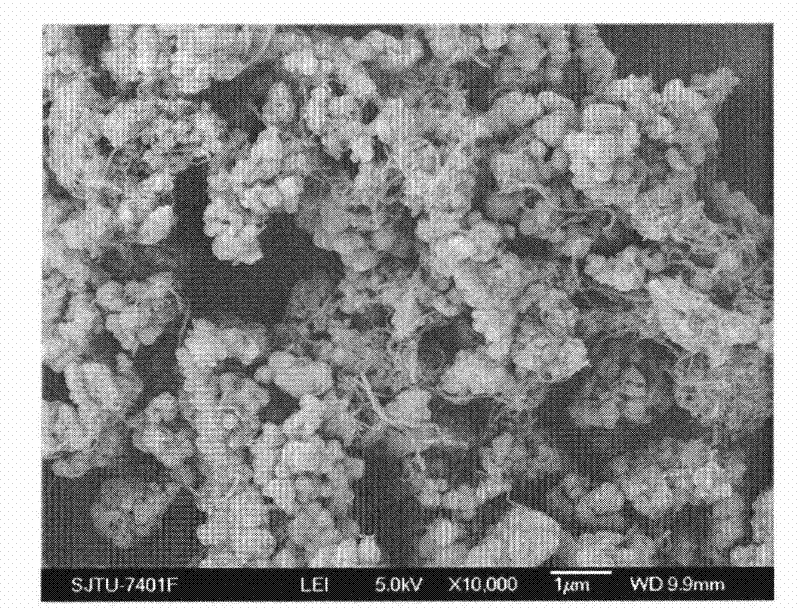

[0033] Mix 0.1g of carbon nanotubes, 6g of elemental sulfur and 1g of polyacrylonitrile, add 0.2g of absolute ethanol as a dispersant, place in an agate ball mill jar equipped with an O-ring, put in agate beads, and start ball milling. The speed of the high-energy ball mill is 250 rpm, and the ball milling time is 2 hours to obtain a uniformly dispersed carbon nanotube / elemental sulfur / polyacrylonitrile mixture; the mixture is transferred from the agate ball mill jar to a quartz boat, and vacuum-dried at 80°C After 2 hours, the dispersant absolute ethanol was removed to obtain a dry carbon nanotube / elemental sulfur / polyacrylonitrile mixture of about 6.83g; the quartz boat with the dry mixture was put into a clean quartz tube, Under the protection of an inert gas, it was kept at 320° C. for 7 hours to obtain 1.74 g of sulfur-based composite active material.

[0034] figure ...

Embodiment 2

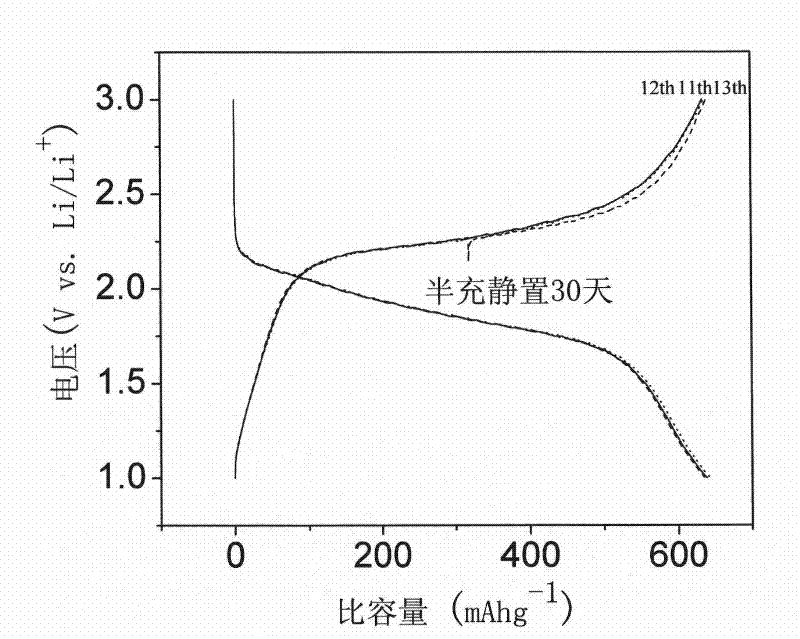

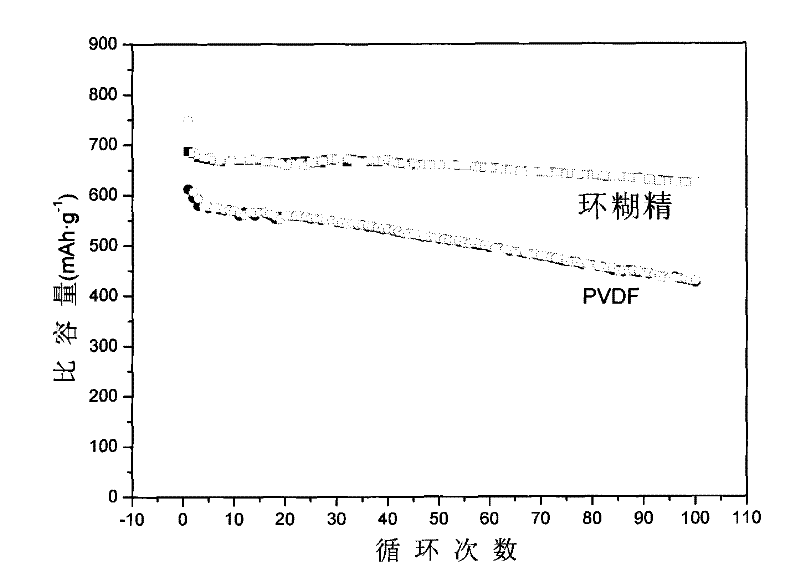

[0037] The sulfur-based composite active material for the secondary lithium-sulfur battery obtained in Example 1 is used as the active material, the binder is β-cyclodextrin, and the carbon conductive agent is Super P carbon black. Put 10mg of β-cyclodextrin and 3mL of distilled water in a mixing cup, heat to 40°C to dissolve the β-cyclodextrin in water to form a colorless solution, then add 10mg of Super P into the mixing cup Carbon black conductive agent and 80mg of sulfur-based composite active material, followed by ultrasonic treatment for 30 minutes, the ultrasonic frequency is 100kHz, then heat preservation at 40°C and magnetic stirring for 3 hours, coat the uniformly mixed slurry on aluminum foil, and vacuum dry at 80°C After 2 hours, after tableting under a pressure of 2 MPa, a sulfur-based positive electrode of a secondary lithium-sulfur battery with β-cyclodextrin as a binder was obtained.

[0038] The prepared sulfur-based positive electrode was punched into pole...

Embodiment 3

[0042] The sulfur-based composite active material for the secondary lithium-sulfur battery obtained in Example 1 is used as the active material, the binder is β-cyclodextrin, and the carbon conductive agent is Super P carbon black. Put 8mg of β-cyclodextrin and 3mL of distilled water in a mixing cup, heat to 40°C to dissolve the β-cyclodextrin in water to form a colorless solution, then add 8mg of Super P into the mixing cup Carbon black conductive agent and 84mg of sulfur-based composite active material, followed by ultrasonic treatment for 30 minutes, the ultrasonic frequency is 100kHz, then kept at 40°C and magnetically stirred for 4 hours, and the obtained uniformly mixed slurry was coated on the aluminum foil, at 80°C After vacuum drying for 2 hours and tableting under a pressure of 2 MPa, a sulfur-based positive electrode for a secondary lithium-sulfur battery with β-cyclodextrin as a binder was obtained.

[0043] The prepared sulfur-based positive electrode was punch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com