Method and battery pole piece for reducing battery self-discharge and improving safety performance

A technology of battery pole piece and safety performance, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems affecting battery safety performance, battery self-discharge, battery short circuit, etc., to improve the overall production quality and reduce battery Self-discharge, the effect of avoiding battery self-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

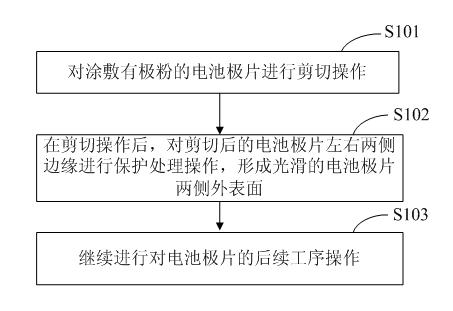

[0025] see figure 1 , figure 2 , the invention provides a method for reducing battery self-discharge and improving safety performance, comprising the following steps:

[0026] Step S101: During the production process of the battery pole piece, the battery pole piece coated with pole powder (positive pole powder or negative pole powder) is sheared;

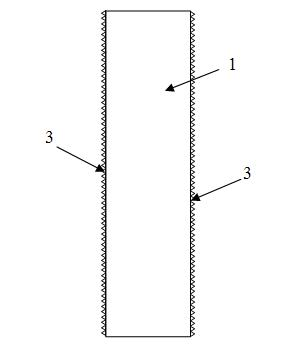

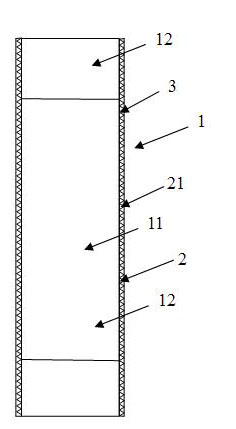

[0027] Step S102: After the shearing operation, protect the left and right edges of the cut battery pole piece to form smooth outer surfaces on both sides of the battery pole piece;

[0028] Step S103: Then continue to perform subsequent operations on the battery pole piece (such as battery pole piece winding, battery assembly process).

[0029] It should be noted that, for step S101, after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com