Electrochemical power-supply composite membrane and preparation method thereof

A composite diaphragm and electrochemical technology, applied in the field of electrochemical power supply, can solve the problems of non-woven diaphragm, excessive pores, self-discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A composite separator for electrochemical power supply and its preparation method:

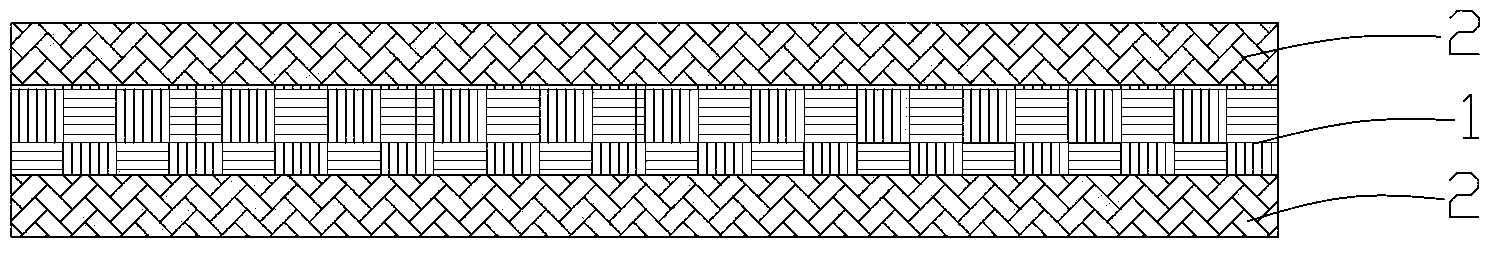

[0037] The composite diaphragm structure of the electrochemical power source is as follows figure 1 As shown, it includes an oxidized aluminum mesh layer 1 and a polyvinylidene fluoride-hexafluoropropylene copolymer layer 2 combined with both sides of the aluminum mesh layer 1 . Wherein, the thickness of the polyvinylidene fluoride-hexafluoropropylene copolymer layer 2 is 10 μm, and the thickness of the aluminum mesh layer 1 is 30 μm.

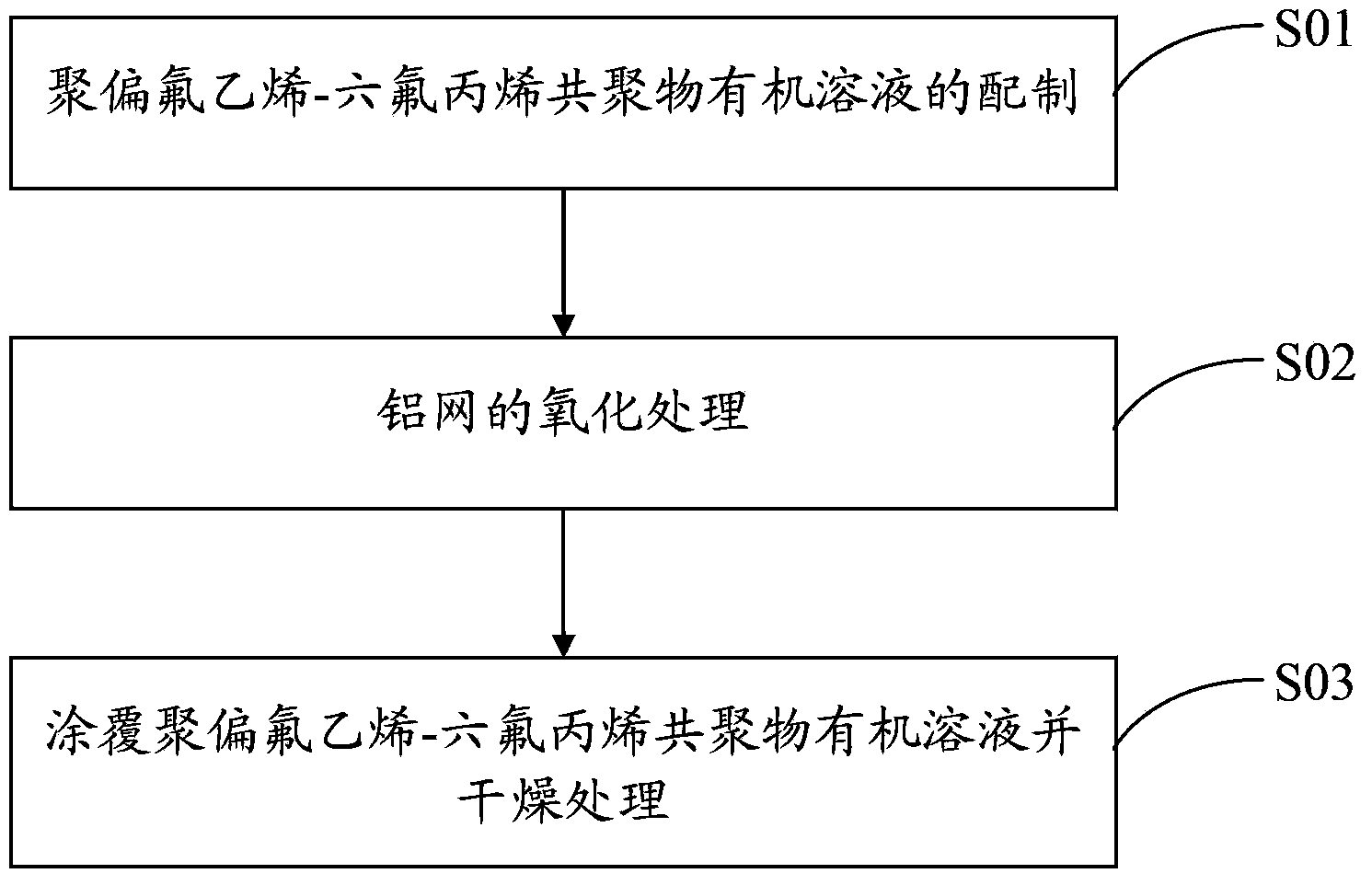

[0038] The preparation method of the electrochemical power composite diaphragm:

[0039] Step S11. Preparation of polyvinylidene fluoride-hexafluoropropylene copolymer organic solution: Take a certain amount of PVDF-HFP with a HFP content of 2% and add it to a container containing a certain amount of acetone, and stir evenly to obtain PVDF-HFP 10% acetone solution;

[0040] Step S12. Oxidation treatment of the aluminum mesh: place an aluminum mesh wit...

Embodiment 2

[0044] A composite separator for electrochemical power supply and its preparation method:

[0045] The structure of the composite diaphragm for electrochemical power source is the same as that of the composite diaphragm for electrochemical power source in Example 1. Wherein, the thickness of the polyvinylidene fluoride-hexafluoropropylene copolymer layer is 15 μm, and the thickness of the aluminum mesh layer 1 is 40 μm.

[0046] The preparation method of the electrochemical power composite diaphragm:

[0047] Step S21. Preparation of polyvinylidene fluoride-hexafluoropropylene copolymer organic solution: Take a certain amount of PVDF-HFP with a HFP content of 5% and add it to a container containing a certain amount of chloroform, and stir evenly to obtain PVDF-HFP 10% chloroform solution;

[0048] Step S22. Oxidation treatment of the aluminum mesh: place an aluminum mesh with a thickness of 25 microns and a pore size of 10 microns in a muffle furnace at 400° C. for 12 hours,...

Embodiment 3

[0052] A composite separator for electrochemical power supply and its preparation method:

[0053] The structure of the composite diaphragm for electrochemical power source is the same as that of the composite diaphragm for electrochemical power source in Example 1. Wherein, the thickness of the polyvinylidene fluoride-hexafluoropropylene copolymer layer is 10 μm, and the thickness of the aluminum mesh layer 1 is 20 μm.

[0054] The preparation method of the electrochemical power composite diaphragm:

[0055] Step S31. Preparation of polyvinylidene fluoride-hexafluoropropylene copolymer organic solution: Take a certain amount of PVDF-HFP with a HFP content of 1% and add it to a container containing a certain amount of tetrahydrofuran, and stir evenly to obtain the PVDF-HFP content 20% tetrahydrofuran solution;

[0056] Step S22. Oxidation treatment of the aluminum mesh: place an aluminum mesh with a thickness of 10 microns and a pore size of 95 microns in a muffle furnace an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com