Method for compacting coal in a manner suitable for coke oven chambers

一种炼焦炉、压实体的技术,应用在炼焦炉、带机械装置输送的炼焦炉、化学仪器和方法等方向,能够解决没有描述制造压实体等问题,达到优异仓储能力、制造简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

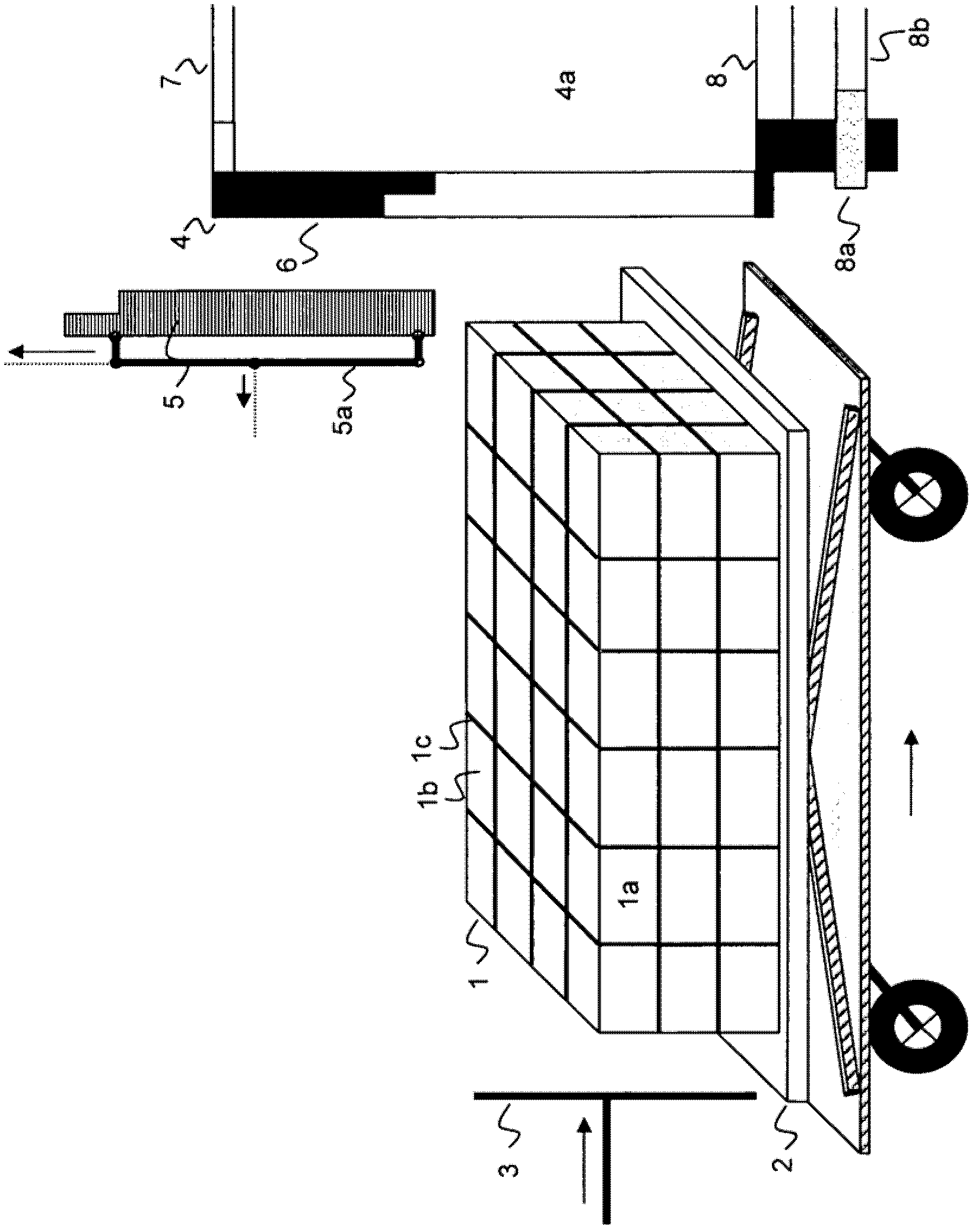

[0031] Here a briquette ( 1 ) is shown which has been divided into a certain number of compacted bodies by means of a cutting device. Here, the compacted bodies (1a, 1b) can be seen on the front side (1a) and from the upper side (1b) of the briquette (1), wherein the compacted bodies are separated by the cutting surface (1c). Here a real briquette (1) can be seen on a running car (2). The car is pushed into the coke oven cavity (4a) by means of a pushing device (3). Here it can be seen that the coke oven chamber is open. Also visible is the coke oven chamber (4), the coke oven chamber door (5) with the opening mechanism (5a), the wall (6) including the coke oven chamber door, part of the coke oven chamber cover (7) and the Part of the bottom (8) of the coke oven chamber with the opening (8a) for the secondary air base (8b).

[0032] List of reference signs

[0033] 1 briquette

[0034] 1a Coal compaction body, visible from the front side of the briquette

[0035] 1b Coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com