Condensation pipe and filtering module using same

A filtration module and condensation tube technology, applied in the direction of steam condensation, total evaporation, semi-permeable membrane separation, etc., can solve the problems of low specific surface area of membrane, large fiber pressure difference, inconvenience, etc., to improve the permeation flux and increase the flux Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

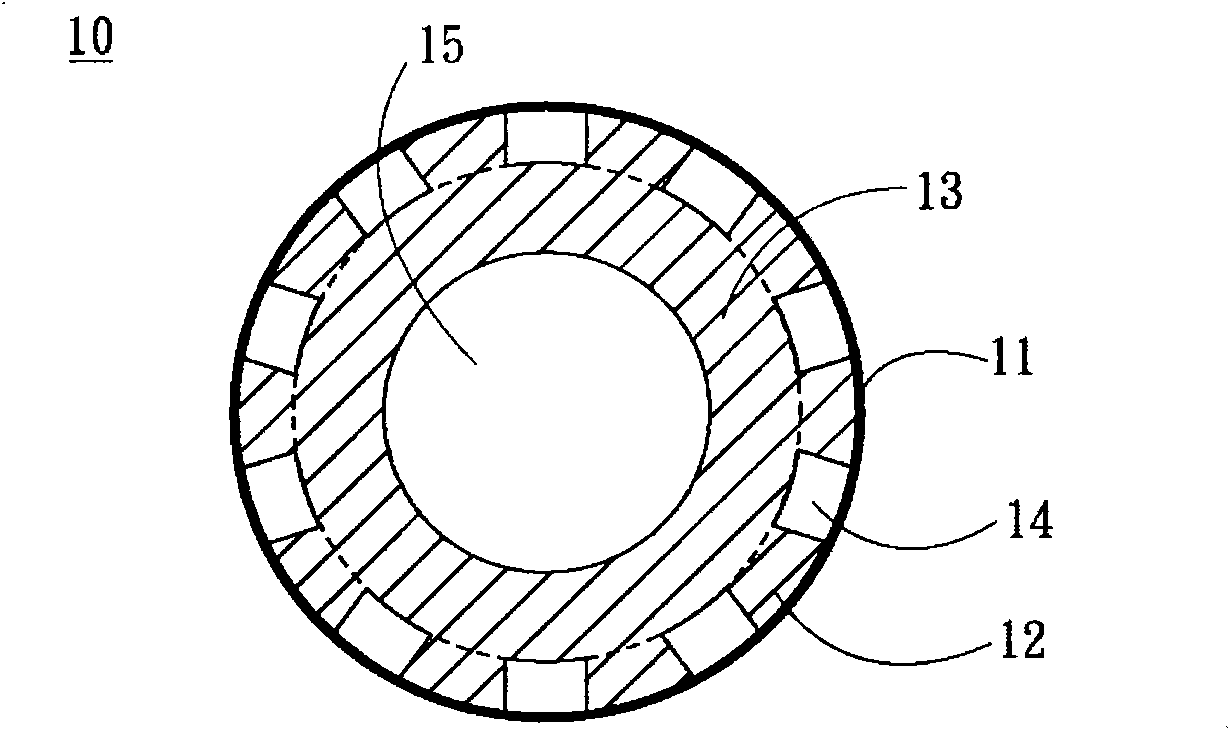

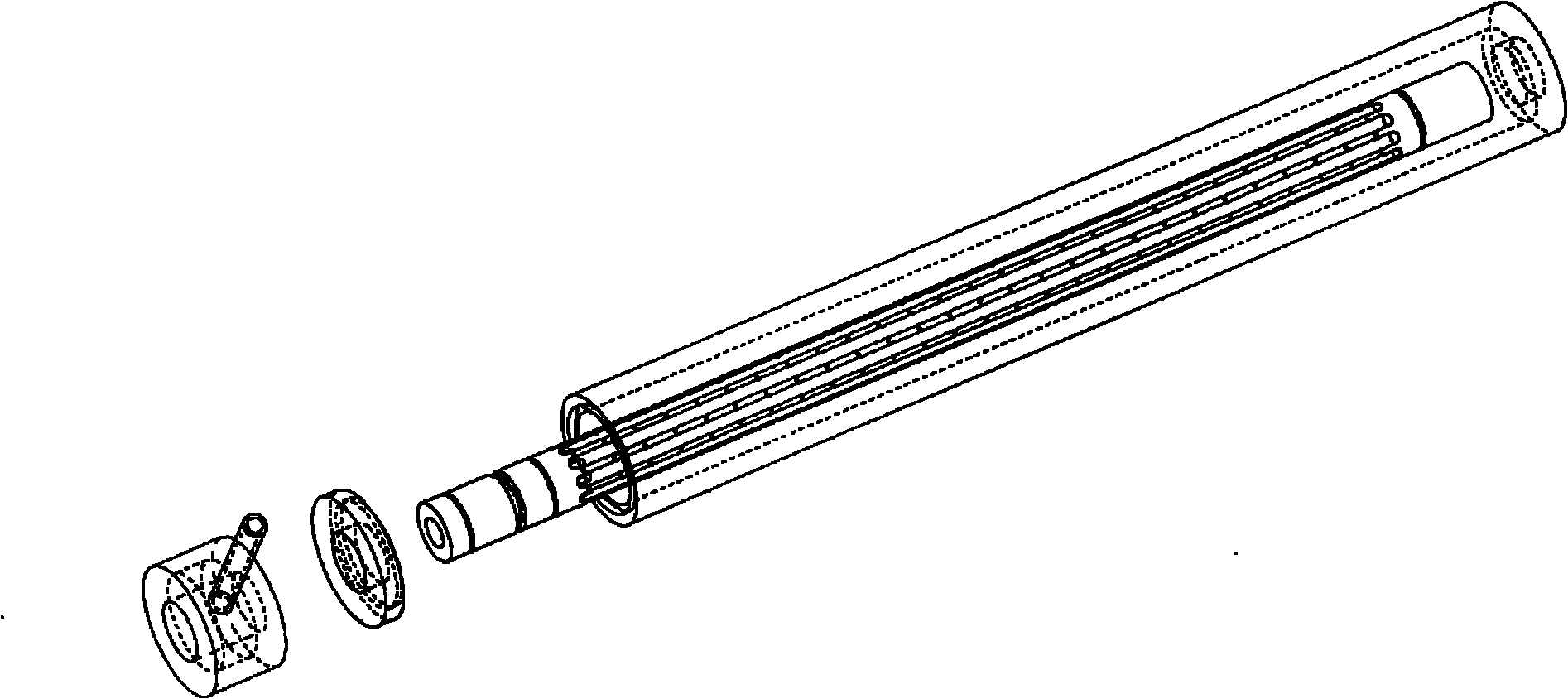

[0058] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, and Features and their functions are described in detail below.

[0059] Some embodiments of the present invention will be described in detail as follows. However, in addition to the following descriptions, the present invention can also be widely implemented in other embodiments, and the protection scope of the present invention is not limited by the embodiments, which shall prevail by the protection scope of the claims. Moreover, in order to provide a clearer description and an easier understanding of the present invention, various parts in the drawings have not been drawn according to their relative sizes, and some dimensions have been exaggerated compared with other relevant dimensions; irrelevant details hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com