Online recycling crushers

A pulverizer and recycled material technology, which is applied in the direction of plastic recycling, recycling technology, mechanical material recycling, etc., can solve the problems of difficult control of the discharge speed, easy blockage of the discharge pipe, and no discharge, so as to avoid pollution, Effects of changing production methods and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

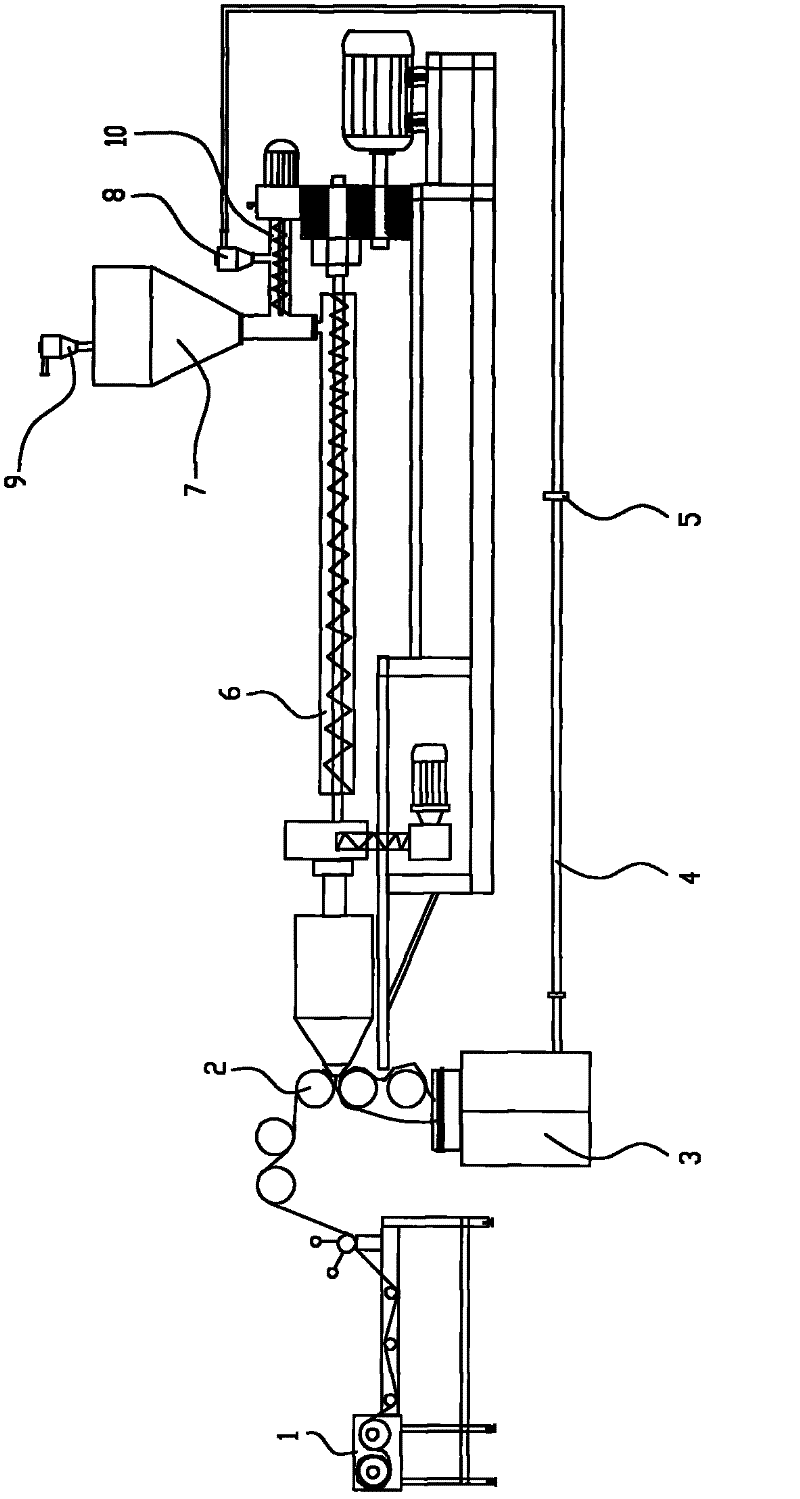

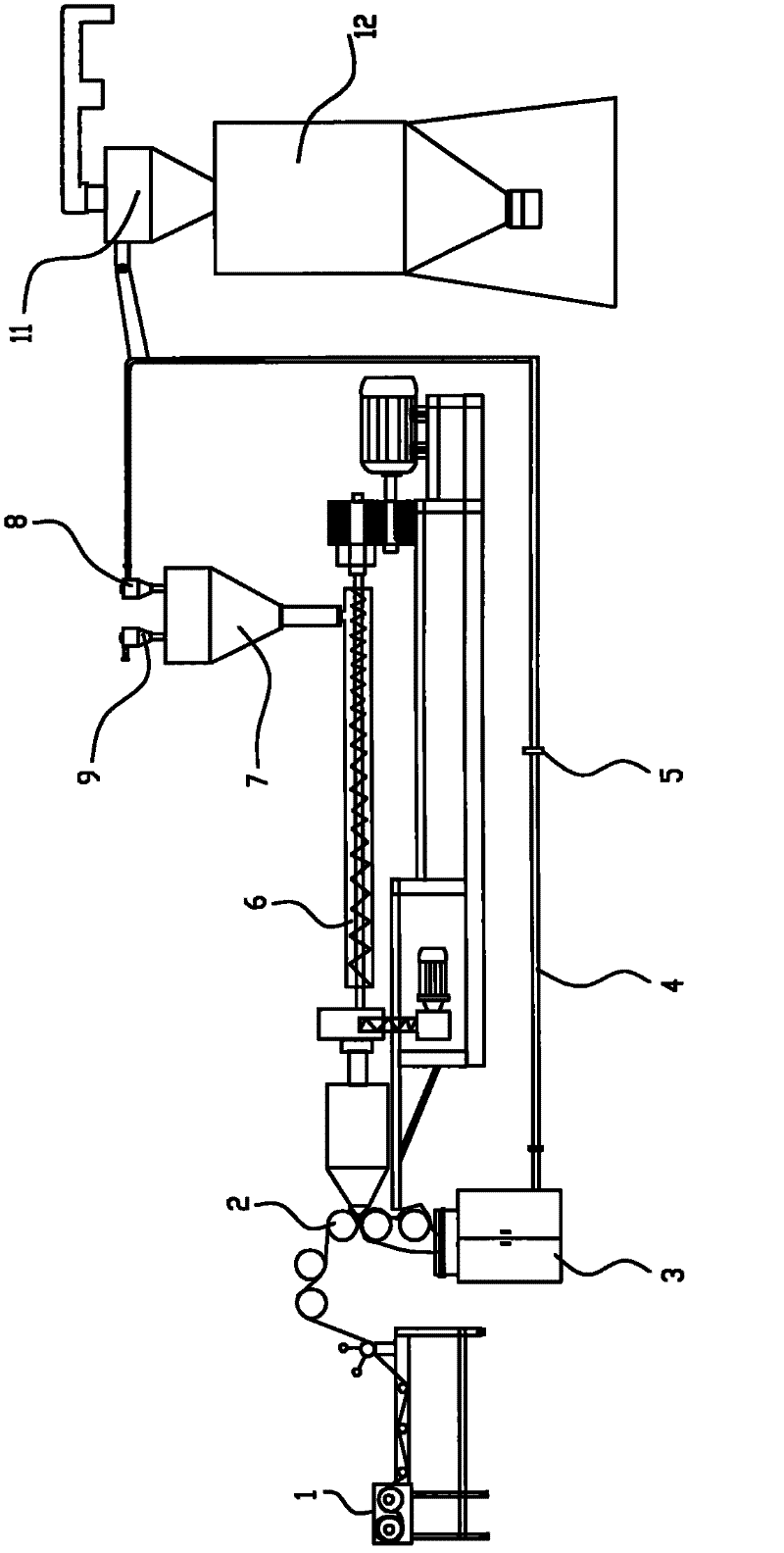

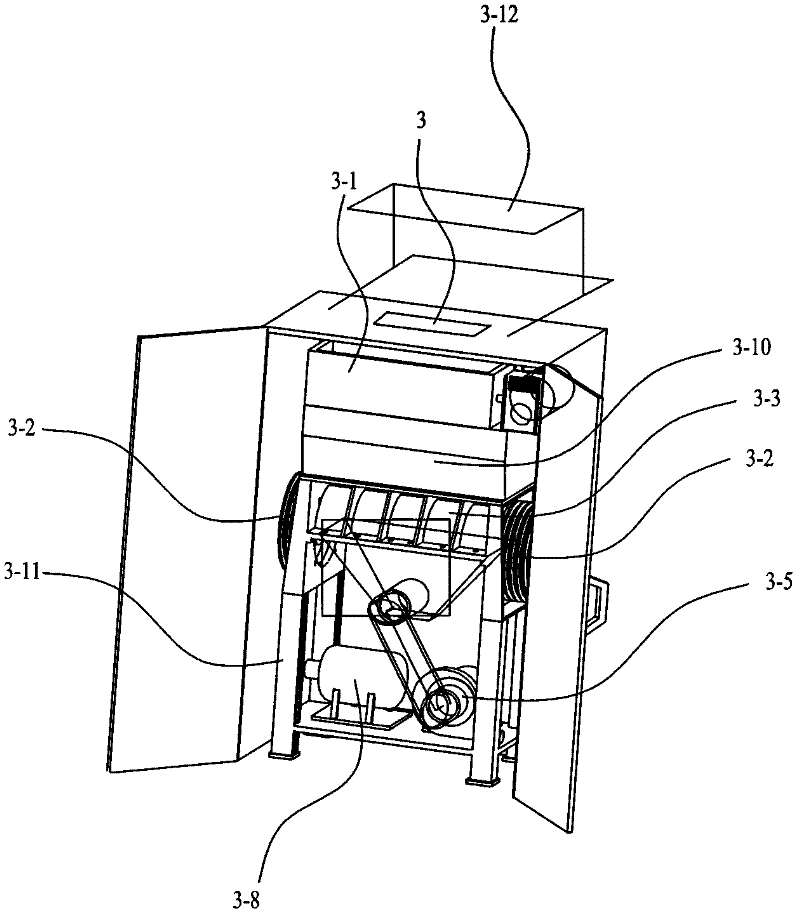

[0014] like figure 1 As shown, the first online recycling pulverizer involved in this embodiment includes: a finished product winding machine 1, a sheet material drum 2, an ear material recycling pulverizer 3, a feeding pipeline 4, a pipeline joint 5, a forming machine screw 6, Raw material hopper 7, recycled material hopper 8, suction machine 9 and extruder 10, the crushed material outlet of ear material recovery pulverizer 3 is connected with recycled material hopper 8 through feeding pipeline 4, pipeline joint 5, and the outlet of recycled material hopper 8 It is connected with the extruder 10, and the outlet of the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com