Multi-layer co-extrusion volatile rust-proof film

A gas-phase anti-rust and multi-layer co-extrusion technology, applied in the field of plastic film, can solve the problems of short anti-rust time and achieve the effect of long anti-rust period and increased concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

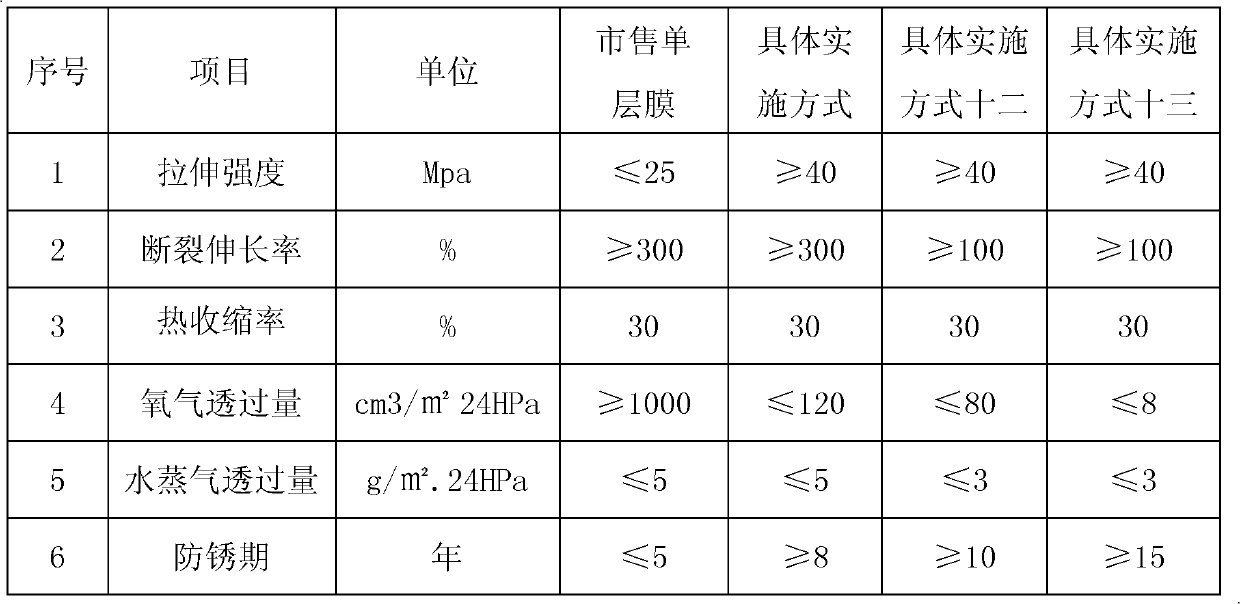

[0007] Specific implementation mode 1: In this embodiment, the multi-layer co-extruded gas-phase anti-rust film has a three-layer, five-layer or seven-layer structure; the multi-layer co-extruded gas-phase anti-rust film has a three-layer structure, and each layer from the inside to the outside is A / B / G; multi-layer co-extruded vapor phase anti-corrosion film has a five-layer structure, and each layer from the inside to the outside is A / B / D / B / G, A / B / C / B / G or A / B / C / D / G; multi-layer co-extruded vapor phase antirust film is a seven-layer structure, and each layer from the inside to the outside is A / B / C / D / C / B / G or A / B / C / D / E / F / G; the material of the A layer is a mixture of 80% to 95% (mass) polyolefin and 5% to 20% (mass) gas phase rust inhibitor or 80% to 95% (mass) polyamide and 5% to 20% (mass) % (mass) of a mixture of vapor phase antirust agents, the material of the B layer is a mixture of 90% to 98% (mass) of an adhesive and 2% to 10% (mass) of a gas phase antirust agent, a...

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment is different from Embodiment 1 in that the polyolefin is polypropylene (abbreviated as PP), polyethylene (abbreviated as PE) or chlorinated polyethylene (abbreviated as EVA). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Embodiment 3: The polyester described in this embodiment and the specific embodiment is ethylene methyl acrylate copolymer (abbreviated as EMA) or ethylene acrylic acid copolymer (abbreviated as EAA).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com