Control method and system for hydraulic control device of continuously variable speed transmission of hybrid power system

A compound power and control device technology, applied in the direction of transmission control, power device, air pressure power device, etc., can solve problems such as poor efficiency, inability to obtain power output results, and inability to fully respond to various vehicle conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to have a further cognition and understanding of the features, purpose and functions of the present invention, the relevant detailed structure and design concept of the device of the present invention will be described below, so that the characteristics of the present invention can be clearly understood, and the detailed statement as follows:

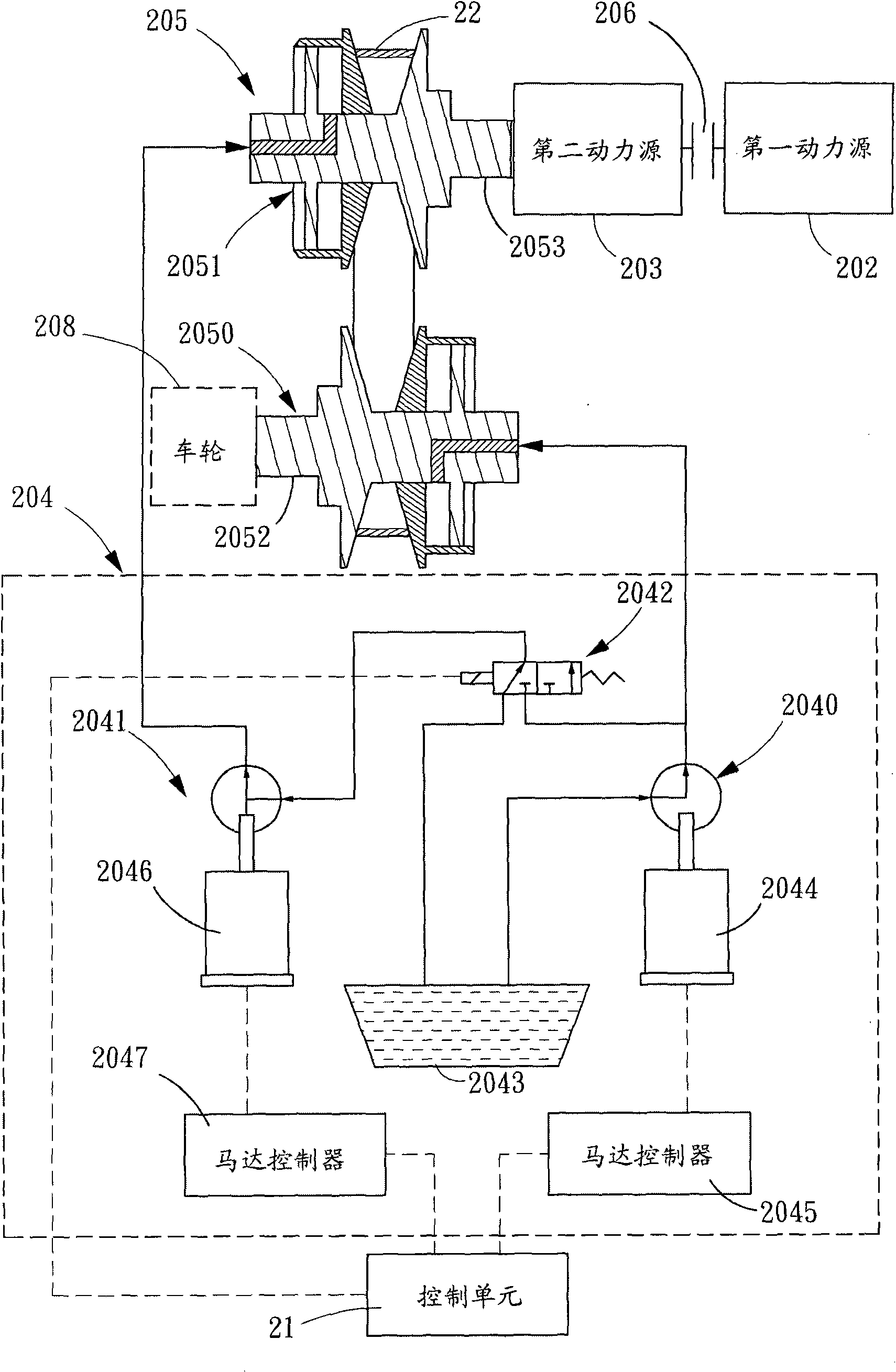

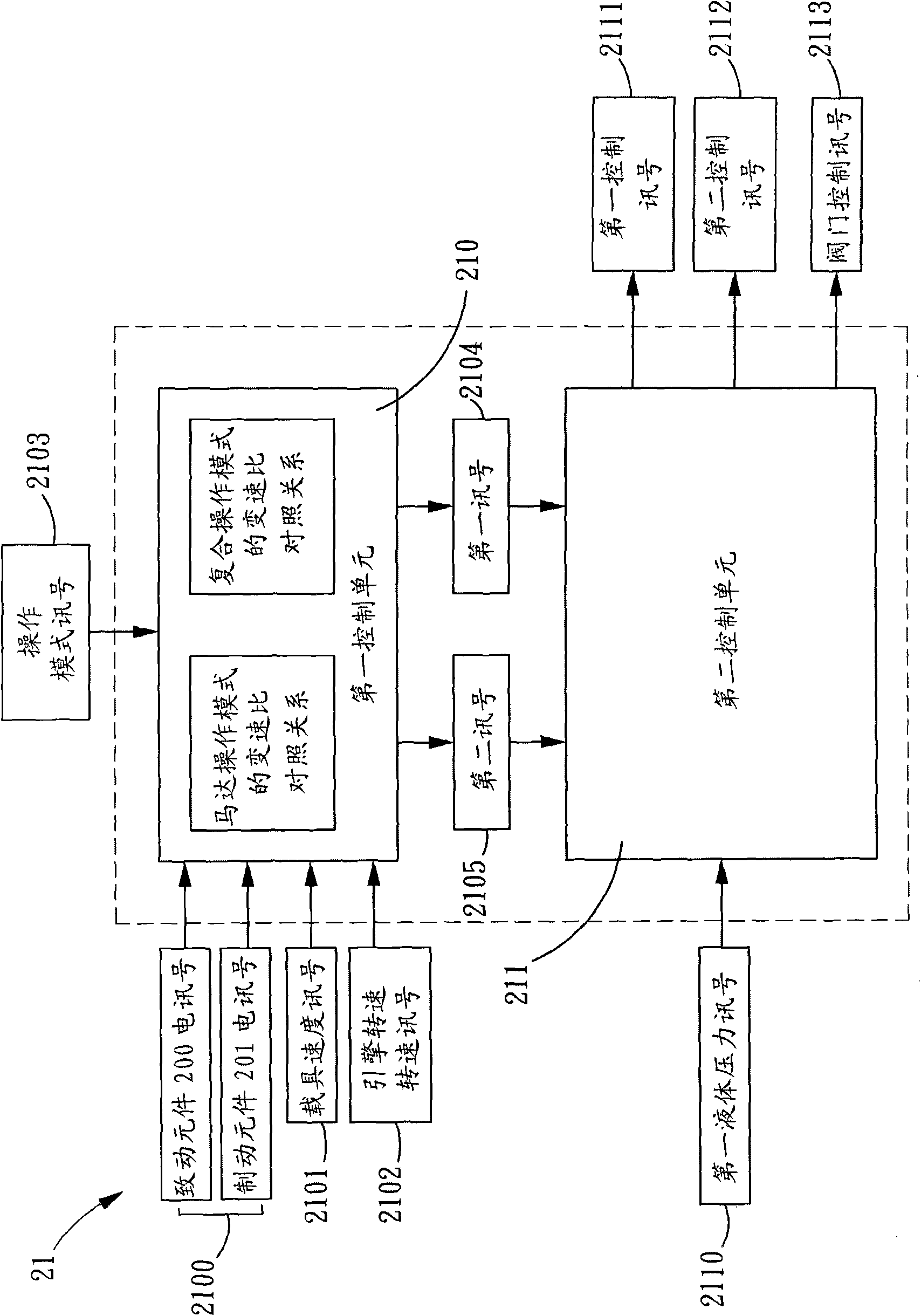

[0071] see figure 1 As shown, this figure is a schematic diagram of the control system of the hydraulic control device of the compound power system continuously variable transmission of the present invention. The control system 2 includes a hybrid power system 20 having two control components. In this embodiment, the control components are respectively an actuating component 200 and a braking component 201 on a carrier 90 . The carrier 90 is a wheeled vehicle, but it is not limited thereto, as long as it is a mobile tool that needs to utilize compound power, it can be the aspect covered by the carrier of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com