Electro-hydraulic system for crawler crane

A technology for crawler cranes and hydraulic systems, applied in cranes, electric vehicles, control drives, etc., can solve the problems of high use and maintenance costs, complex operating procedures, and large shapes, so as to reduce the use and maintenance costs and improve safety performance. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

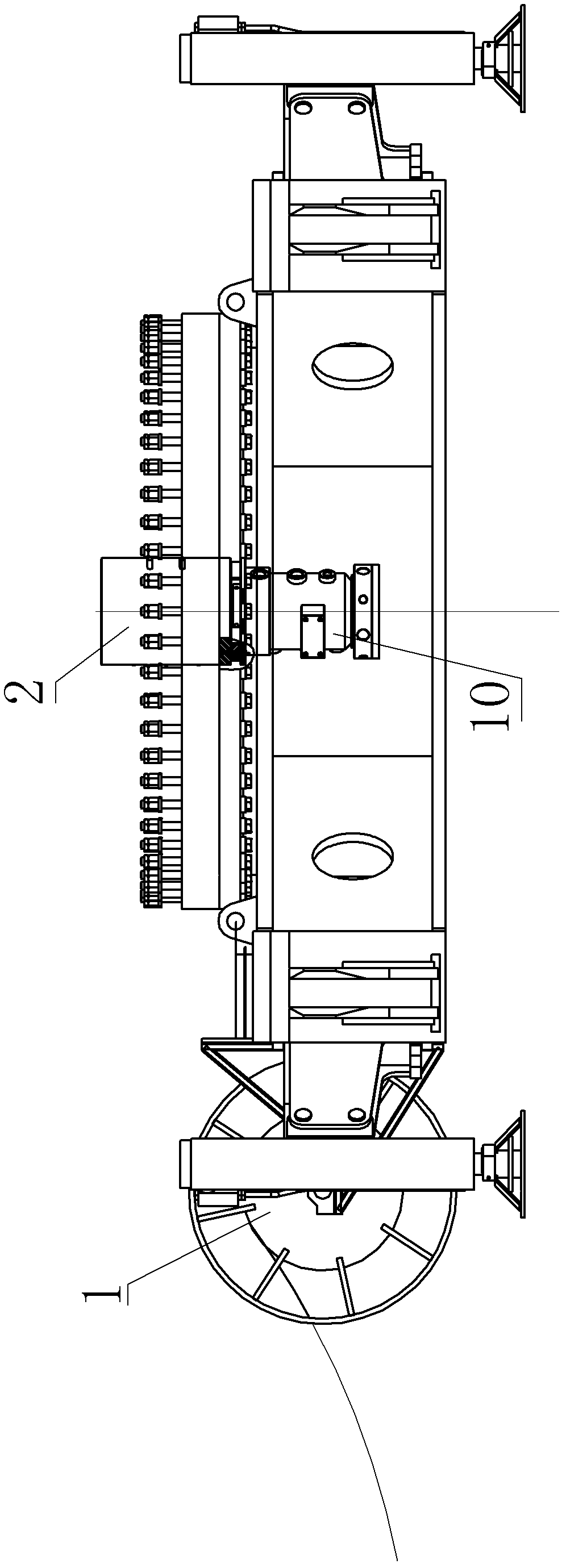

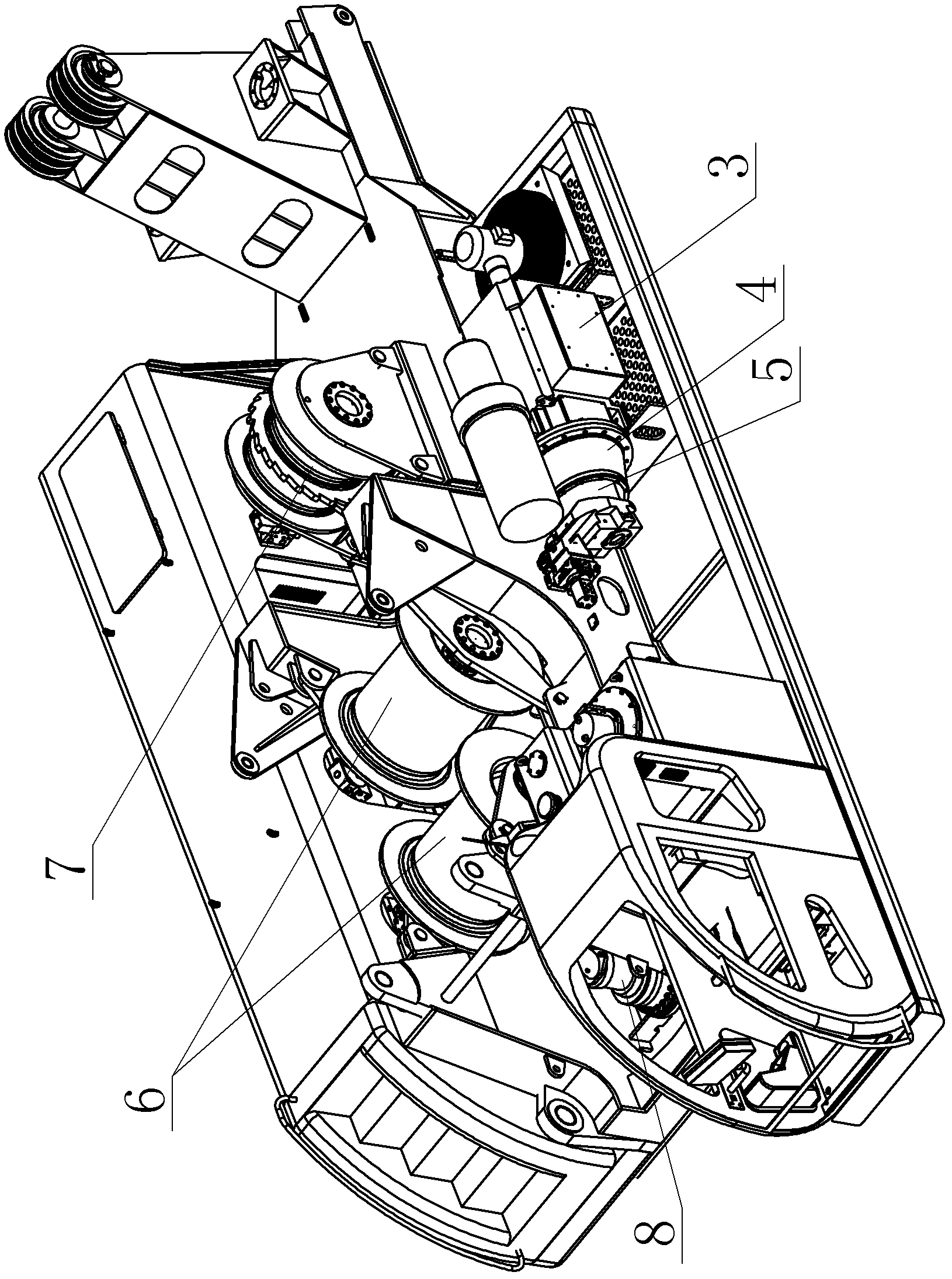

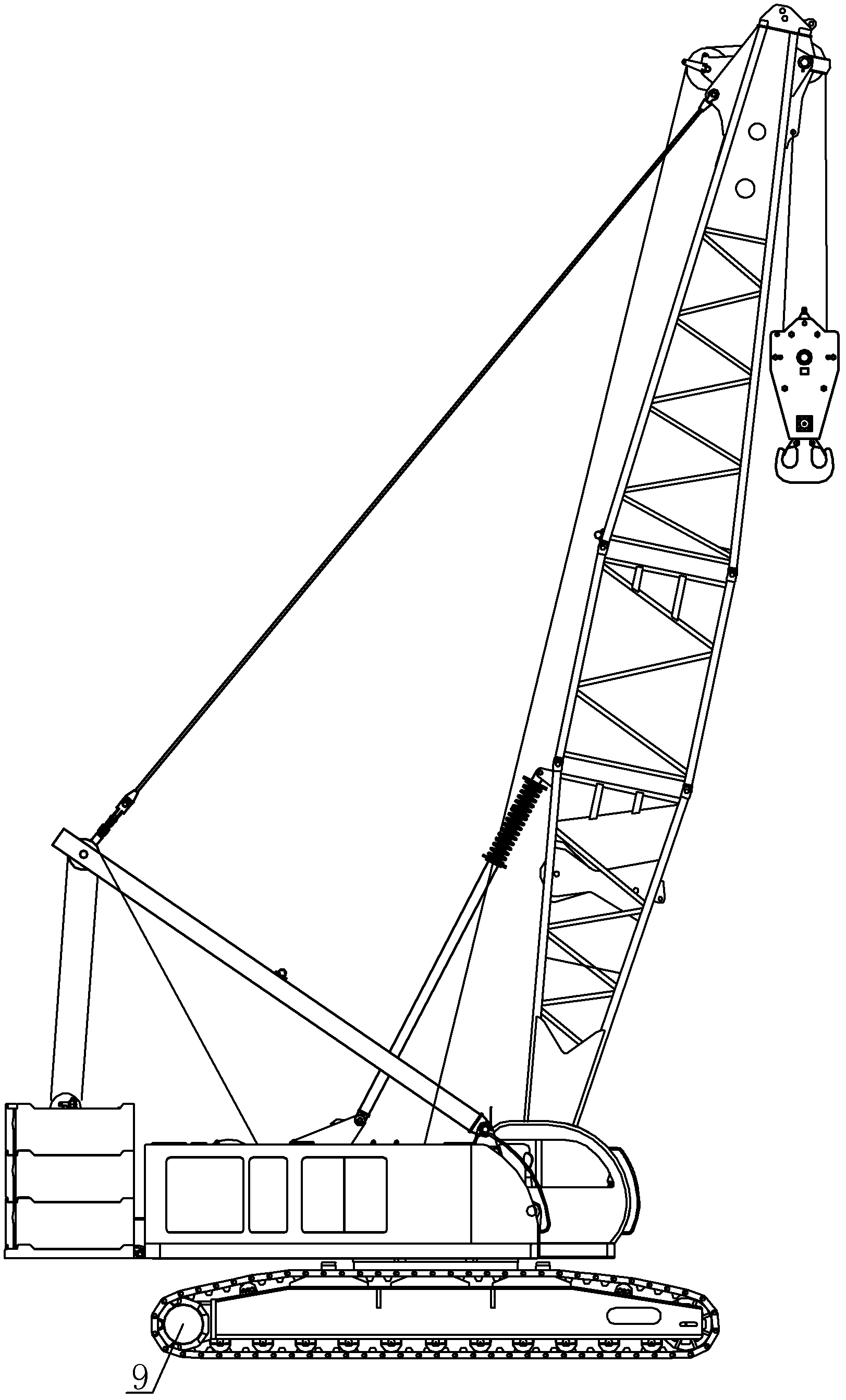

[0018] Such as figure 1 , figure 2 with image 3 As shown in common, the electric hydraulic system of a crawler crane includes a DC speed regulation system, a load regulation system, a hydraulic system and a display. The DC speed regulation system includes a DC speed regulator, which is connected to a DC motor 3. The direct current motor 3 is connected to an oil pump 5 for supplying hydraulic oil to the hydraulic system; the hydraulic system is connected with the hoisting mechanism, luffing mechanism, slewing mechanism, traveling mechanism and each oil cylinder of the crawler crane. The input end of the DC speed regulator is connected to the output end of the slip ring 2, and the input end of the slip ring 2 is connected to an AC power supply through a cable.

[0019] The 380V external AC power supply is connected to the slip ring 2 through a cable. The cable between the AC power supply and the slip ring 2 is wound on the cable drum 1 under the crane. The slip ring 2 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com