Method for connecting external scaffold with wall for large-span and ultra-story-height structures

An external scaffolding and large-span technology, applied in the field of E04G scaffolding and formwork, can solve the problems of unfavorable scaffolding stability and adverse effects on the overall stability of the scaffolding, achieve broad market application prospects, meet construction requirements, and ensure construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in combination with specific embodiments.

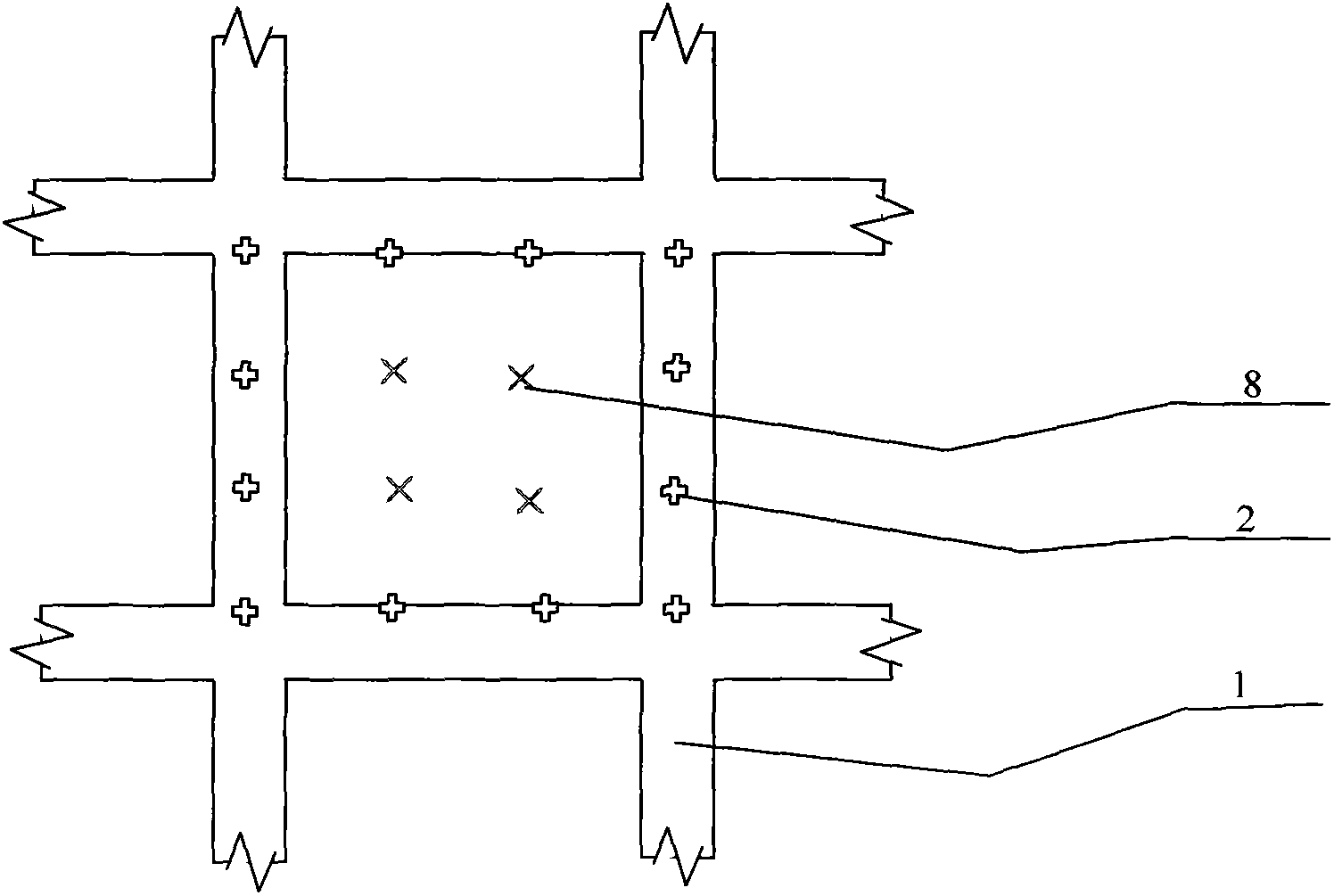

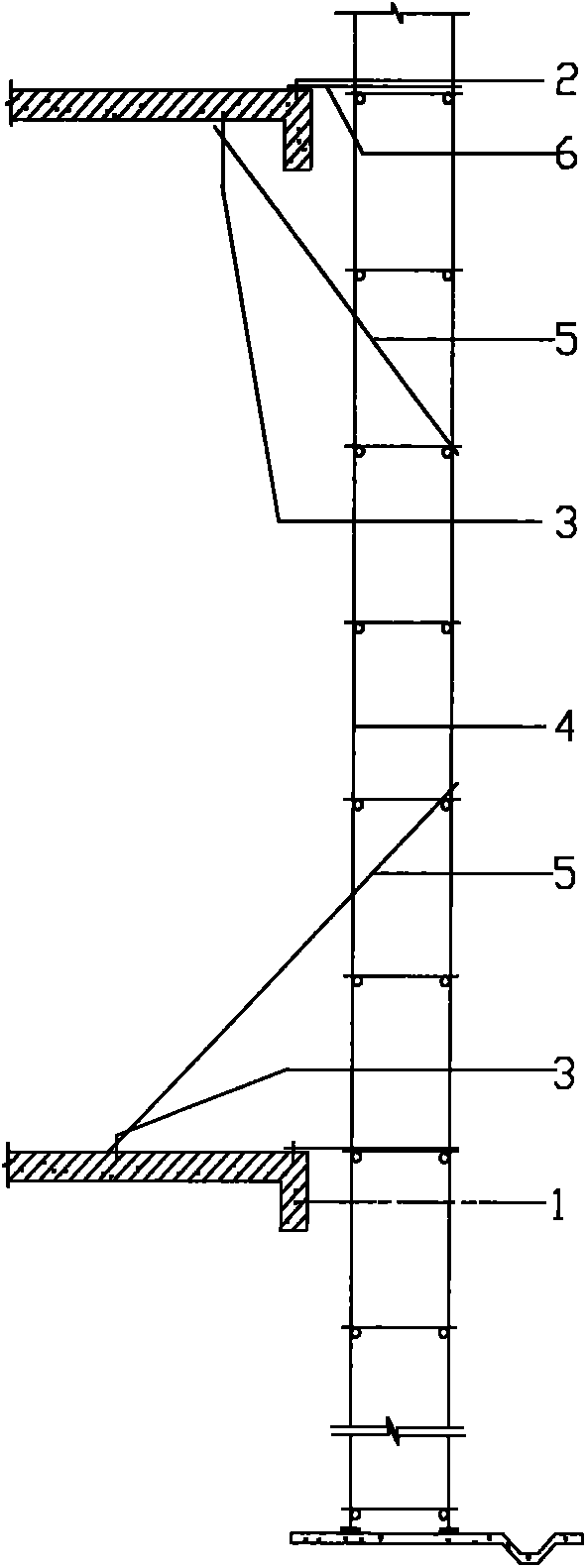

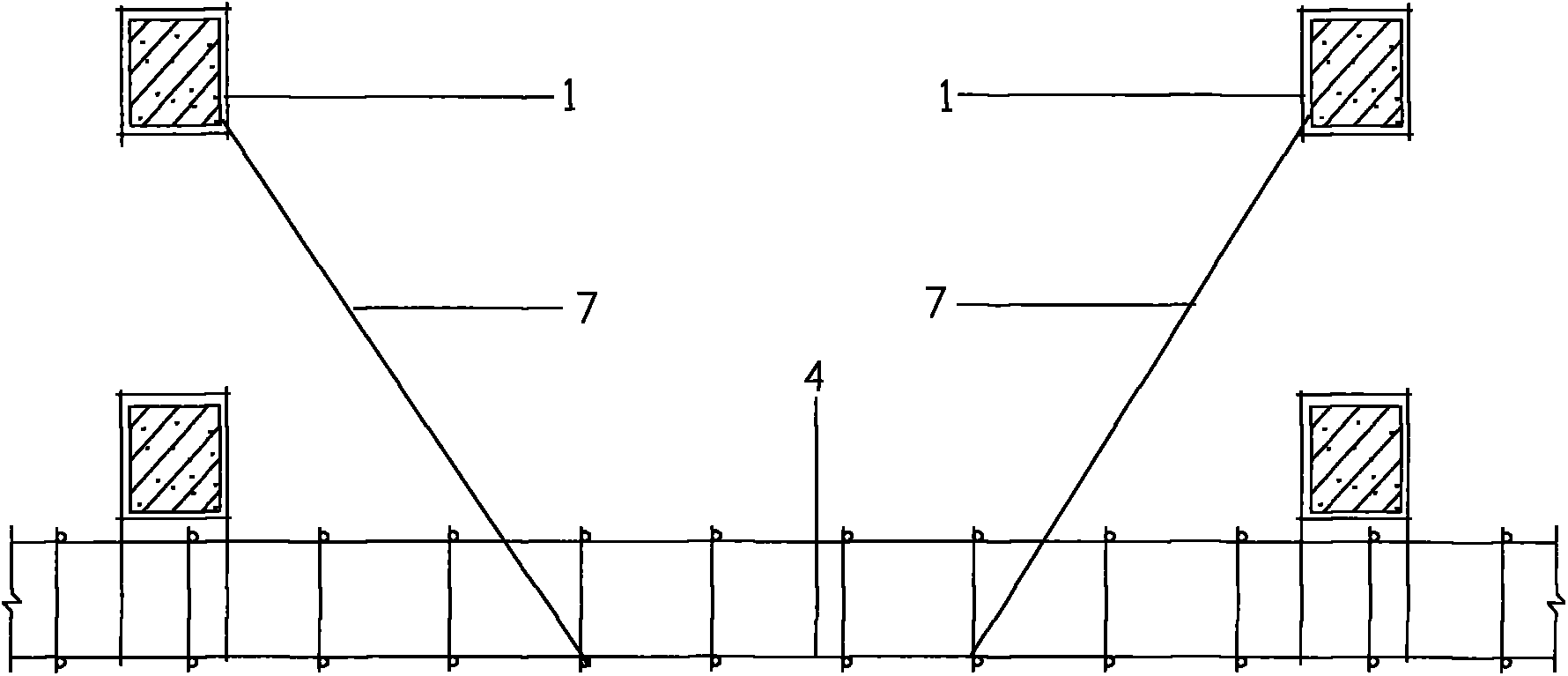

[0015] The pre-embedded connectors 2 on the edge beams and columns of the large-space concrete main structure 1 are used as connecting wall points 3. When super-high structures are encountered (attached figure 1 ), when the setting of the connecting piece 2 between the outer scaffold 4 and the main structure 1 cannot meet the requirements of two steps and three spans, the connecting piece 2 is pre-embedded on the main structure 1, and the vertical cable-stayed steel pipe 5 is used to connect with the outer scaffold 4. The included angle between the drawn steel pipe 5 and the main structure 1 is 45-60°, and the projection of the vertical cable-stayed steel pipe 5 on the floor is perpendicular to the plane of the scaffold; figure 2 ), the external scaffold 4 is reliably connected to the main structure 1 by using the horizontal cable-stayed steel pipe 7, and the projection of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com