Five-lens type image lens and electronic device applying same

A five-chip, imaging technology, applied in the field of optical lenses, can solve the problems of different optical parameters, sacrifice optical properties, etc., achieve the effects of low manufacturing cost, reduce off-axis astigmatism, and improve aberrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] Before the present invention is described in detail, it is noted that in the following description, similar elements are denoted by the same reference numerals.

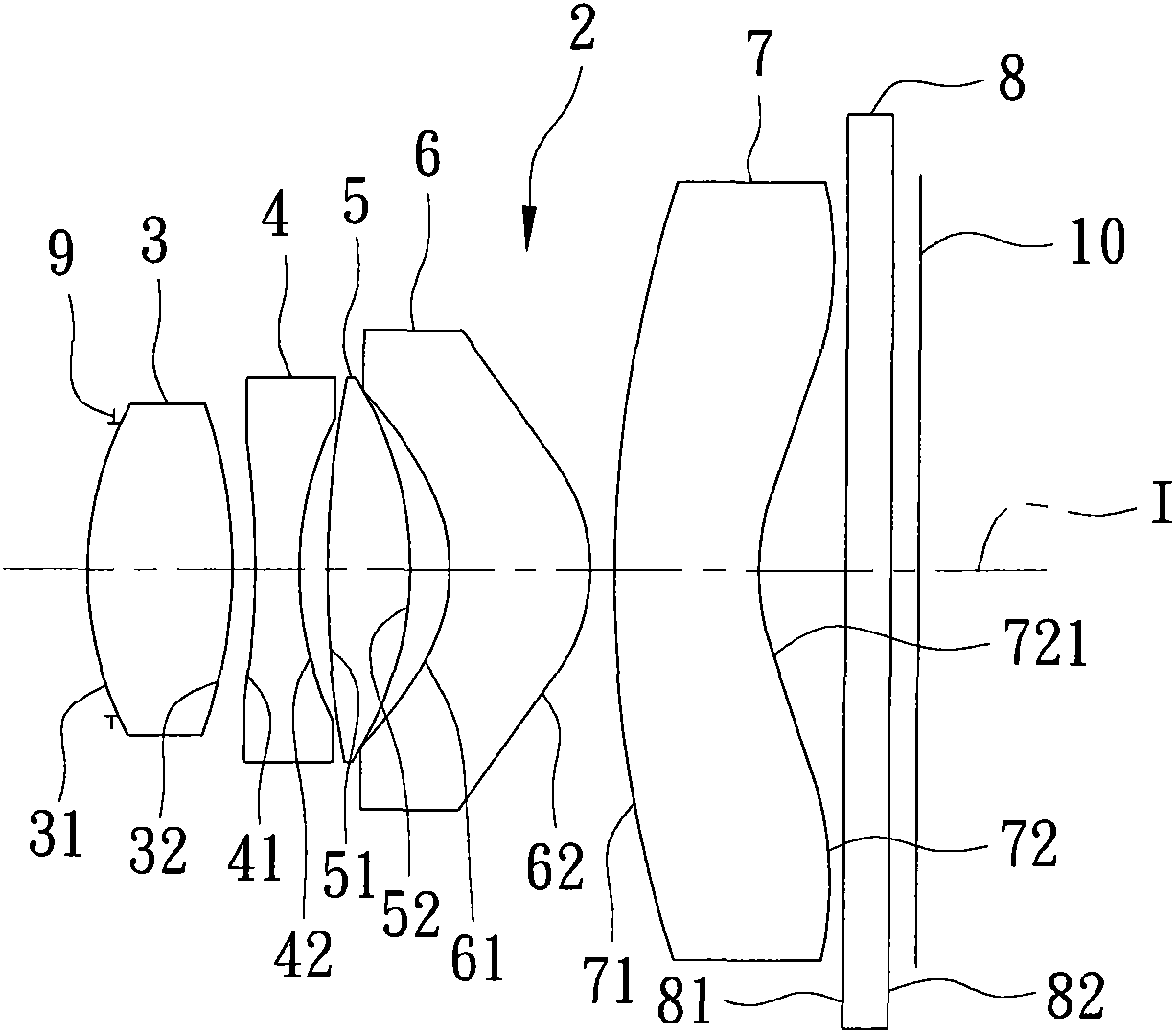

[0030] refer to figure 1 , the five-piece imaging lens 2 of the present invention includes a first lens 3, a second lens 4, a third lens 5, a fourth lens 6, a fifth lens 7, and a filter in sequence from the object side 8. Wherein, the first lens 3 , the second lens 4 , the third lens 5 , the fourth lens 6 and the fifth lens 7 are all made of plastic material. In addition, the imaging lens 2 also includes an aperture 9 (Aperture Stop), and in this embodiment, the aperture 9 is arranged in front of the first lens 3 . When the light emitted by an object to be photographed enters the imaging lens 2, it passes through the aperture 9, the first lens 3, the second lens 4, the third lens 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com