Driving component, cleaning device and ultraviolet sterilizing equipment

A technology for cleaning devices and driving components, which is applied in the direction of electric components, electromechanical devices, cleaning methods and appliances, etc. It can solve the problems of uneven movement speed, vibration, instability, etc., and achieve low cost, long service life and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

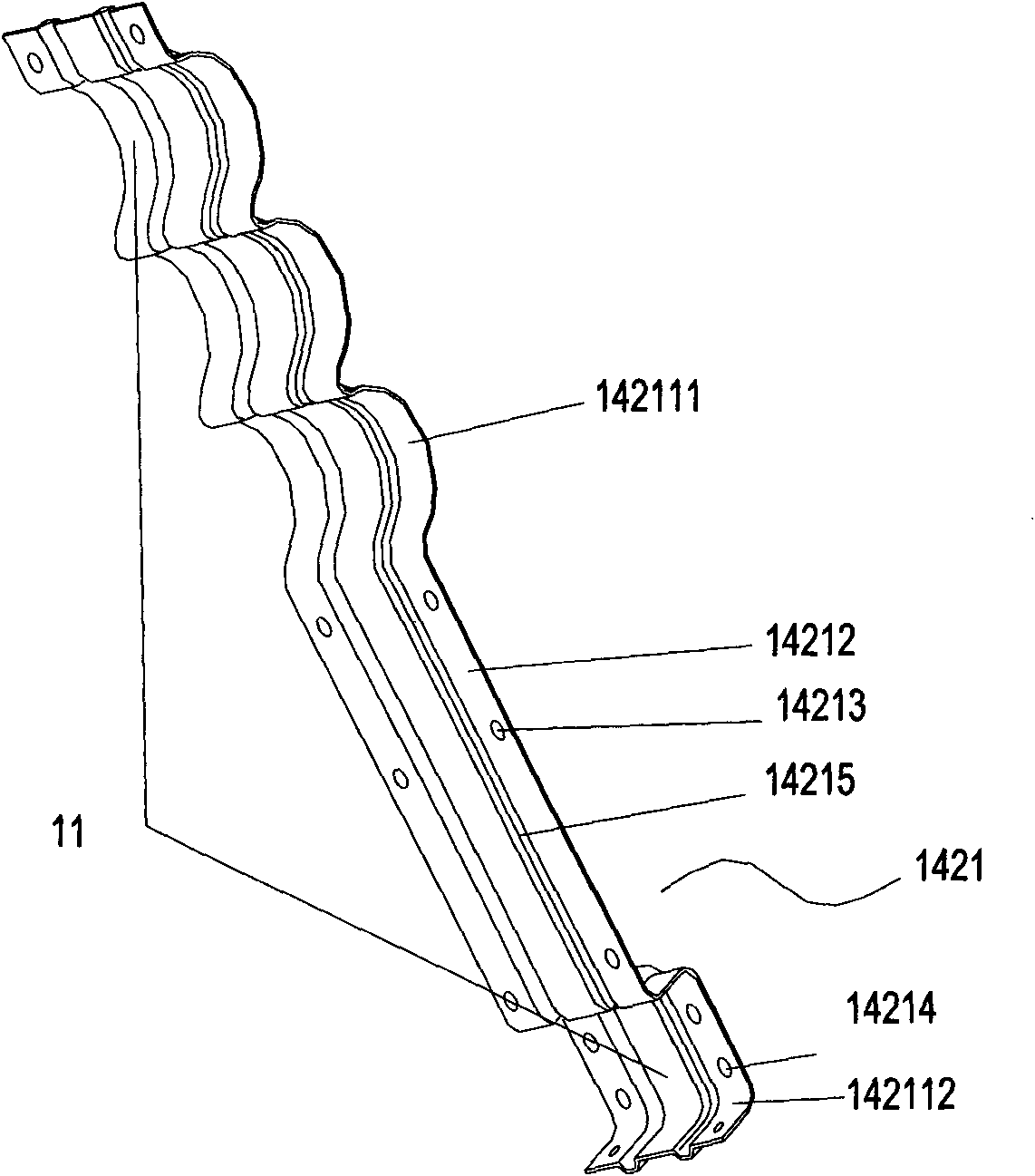

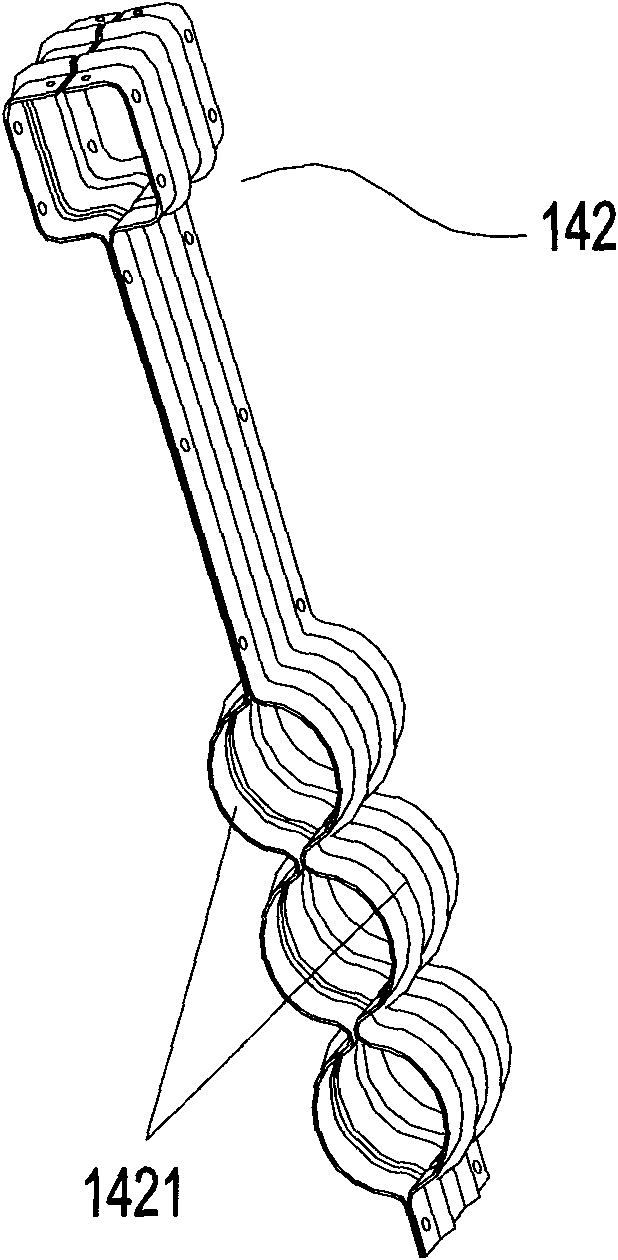

[0033] like Figure 9 As shown, an ultraviolet disinfection device 1 includes a housing 11, a fixed frame 12 supporting the housing 11, a plurality of ultraviolet lamps 13 arranged in parallel up and down on the fixed frame 12, and also includes a housing mounted on the fixed frame 12. The cleaning device 14, such as Figure 7 As shown, the cleaning device 14 includes a wiper 141 for wiping the ultraviolet lamp 13 , a clamping member 142 and a driving assembly 143 .

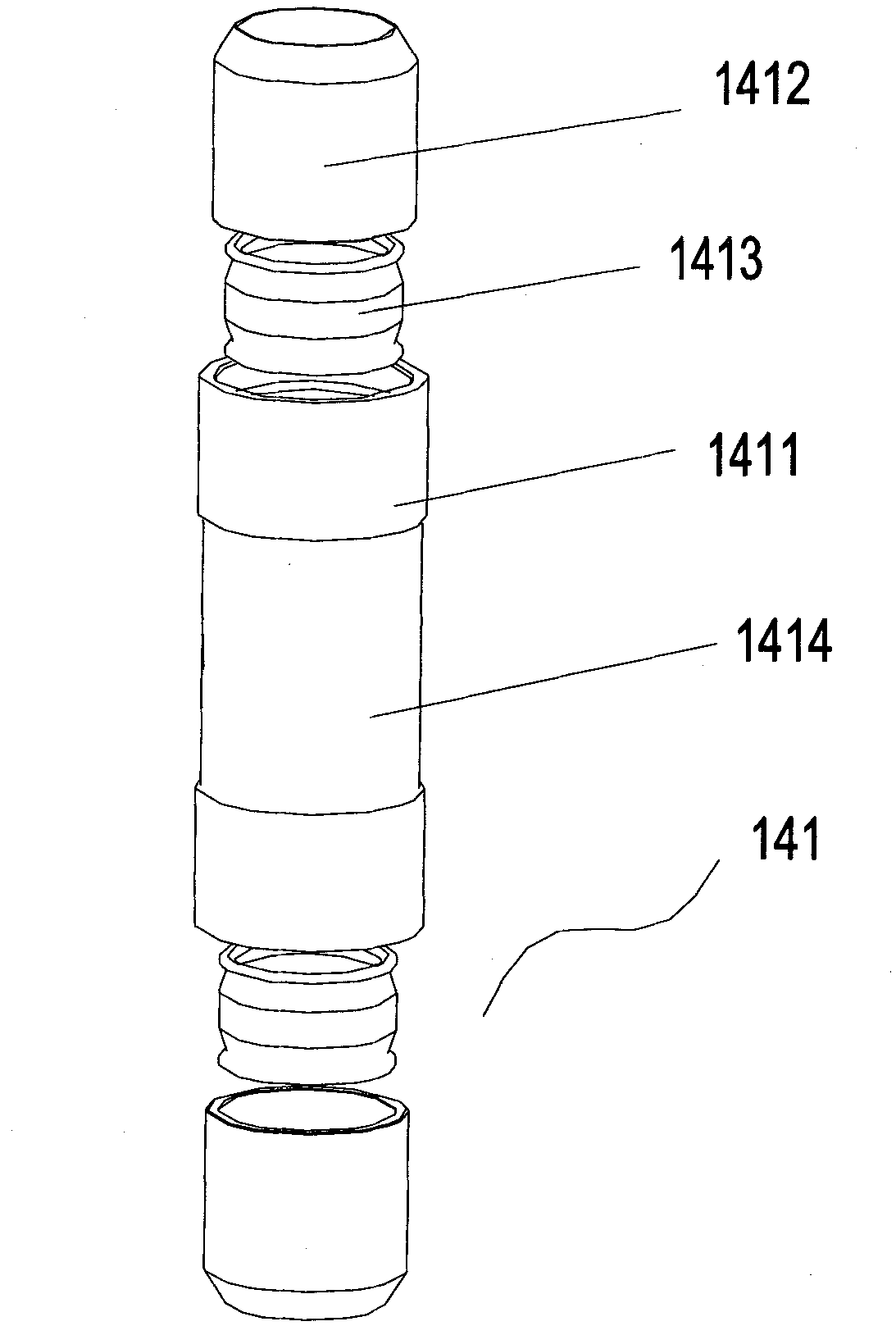

[0034] like image 3 As shown, the wiper 141 includes a wiper main sleeve 1411, two wiper secondary sleeves 1412 respectively installed at both ends of the wiper main sleeve 1411, the wiper main sleeve 1411 and two wipers A wiper inner annular groove (not shown in the figure) is divided between the secondary sleeve pipes 1412, and a wiper apron 1413 for wiping the ultraviolet lamp 13 is arranged in the wiper inner annular groove, and the wiper apron 1413 1413 is sleeved on the ultraviolet lamp tube 13, and the...

Embodiment 2

[0046] On the basis of above-mentioned embodiment 1, combine again Figure 8 and 10 As shown, the cleaning device 14 of the ultraviolet disinfection equipment 1 also includes a sensor 144 that establishes a signal transmission link with the controller. The sensor 144 is set outside the ultraviolet lamp 13. The sensor 144 includes a The wiping unit 1441 and the sensing unit (not shown) for sensing light intensity, the wiping unit 1441 includes a sensor main sleeve 14411, two sensor secondary sleeves 14412 installed at both ends of the sensor main sleeve 14411 A sensor inner annular groove 14413 is provided between the sensor main sleeve 14411 and the two sensor auxiliary sleeves 14412, and a sensor rubber ring (not shown in the figure) for wiping the ultraviolet lamp is arranged in the sensor inner annular groove 14413 ), the sensing unit is arranged on the inner wall of the sensor main sleeve 14411, and the middle part of the sensor main sleeve 14411 is clamped in the arches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com