On-line automatic weighing system for filling and sealing of bottle container

An automatic weighing and container technology, which is applied in the field of food and pharmaceutical packaging equipment, can solve the problems of untimely picking out, high environmental requirements, and inaccurate check weighing, etc., and is conducive to manual debugging and operation, high degree of automation, and improved The effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

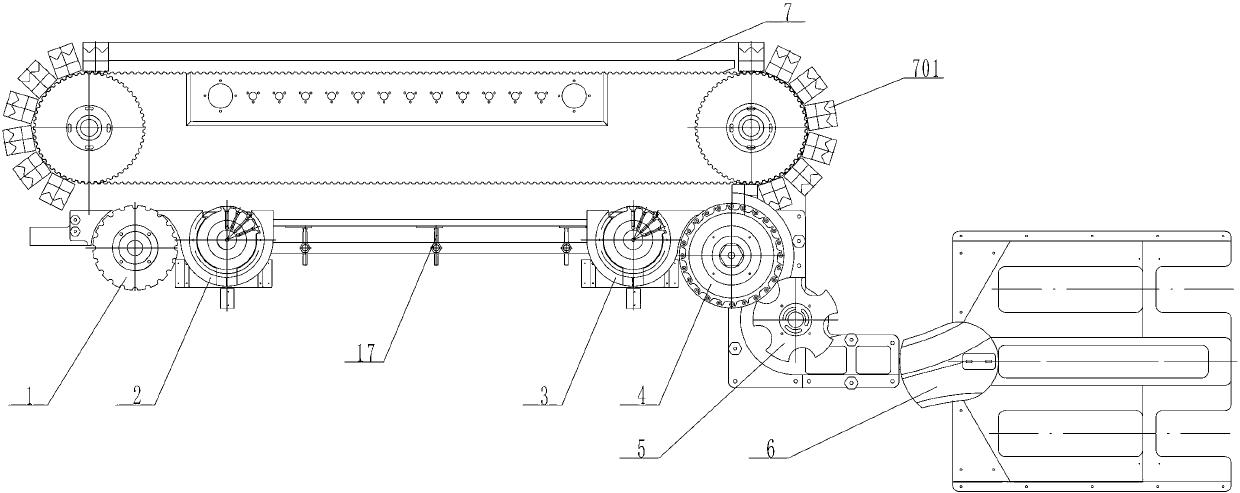

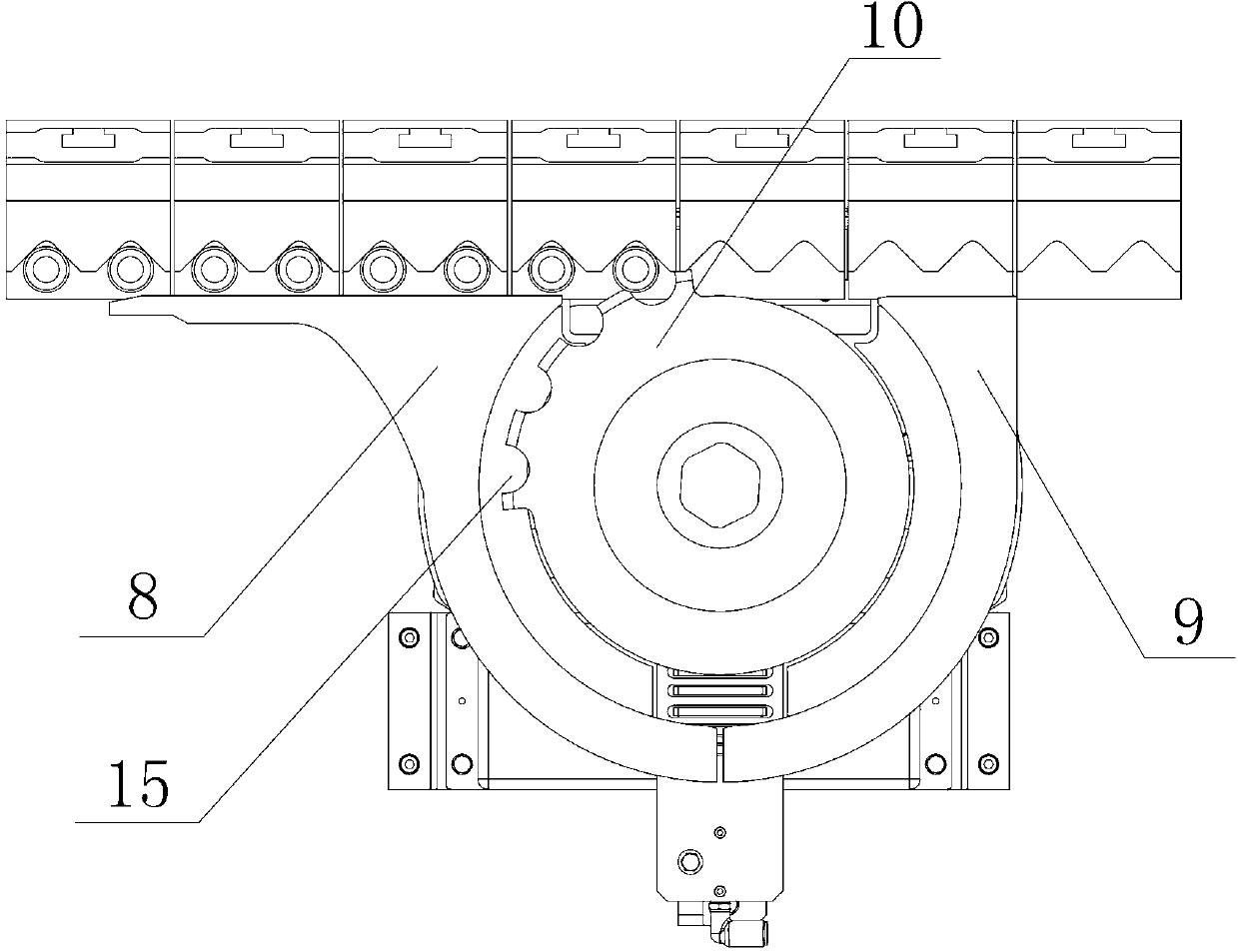

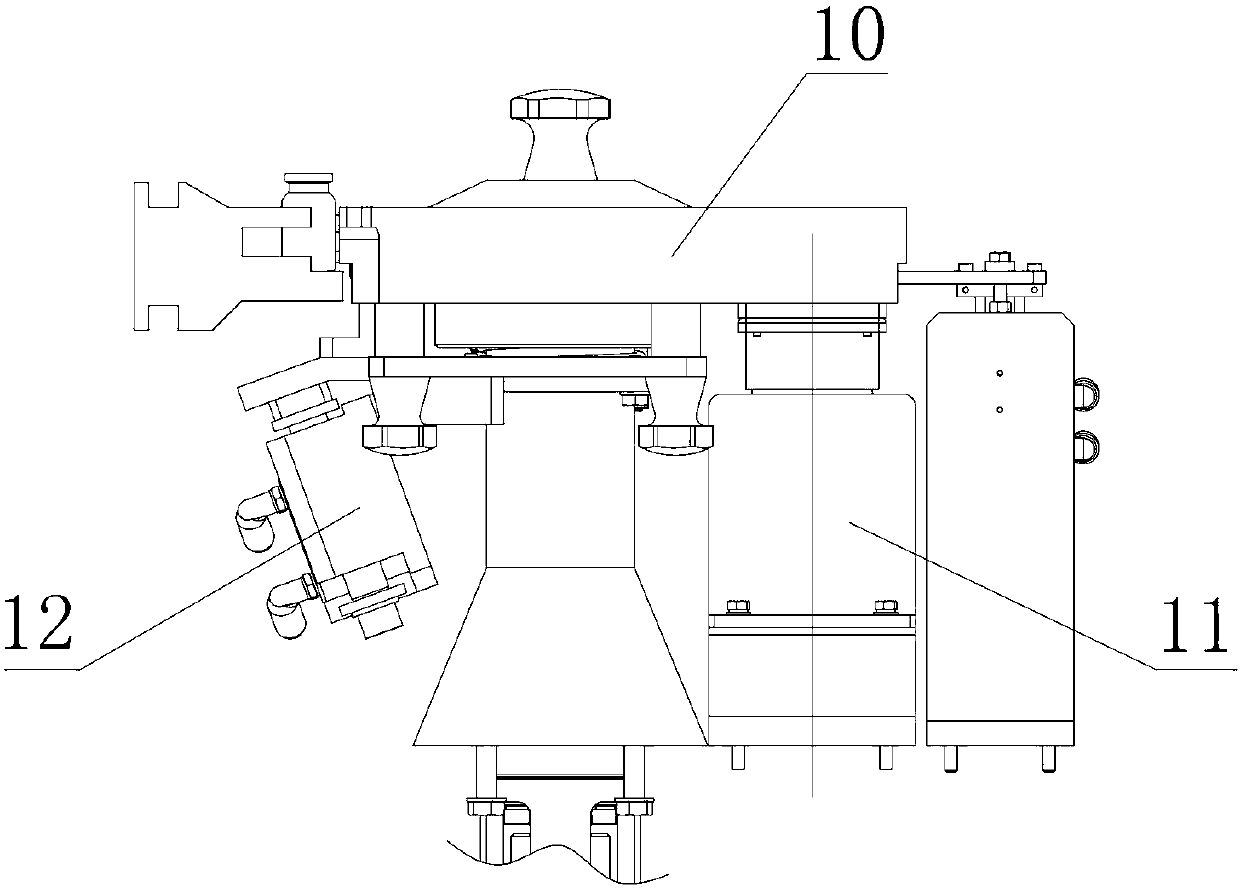

[0027] Such as figure 1 As shown, the online automatic weighing system for bottle container filling and sealing of the present invention includes a control assembly and an empty bottle weighing assembly 2 arranged before the filling station 17, and an empty bottle weighing assembly 2 arranged at the filling station 17 and the stoppering station 4 Between the weighing component 3 after filling, the control component judges whether the filling is qualified according to the weight difference detected by the weighing component 2 of the empty bottle and the weighing component 3 after filling. After the weight detection and judgment are carried out by the difference method, the measurement accuracy is greatly improved. Moreover, the entire weighing assembly is organically combined with the filling and sealing line, which can be completely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com