High-power battery charger and control method thereof

A technology of a battery charger and a control method, which is applied to different battery charging, battery circuit devices, collectors, etc., and can solve the problems of large volume and poor detection accuracy of synchronous rectification circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

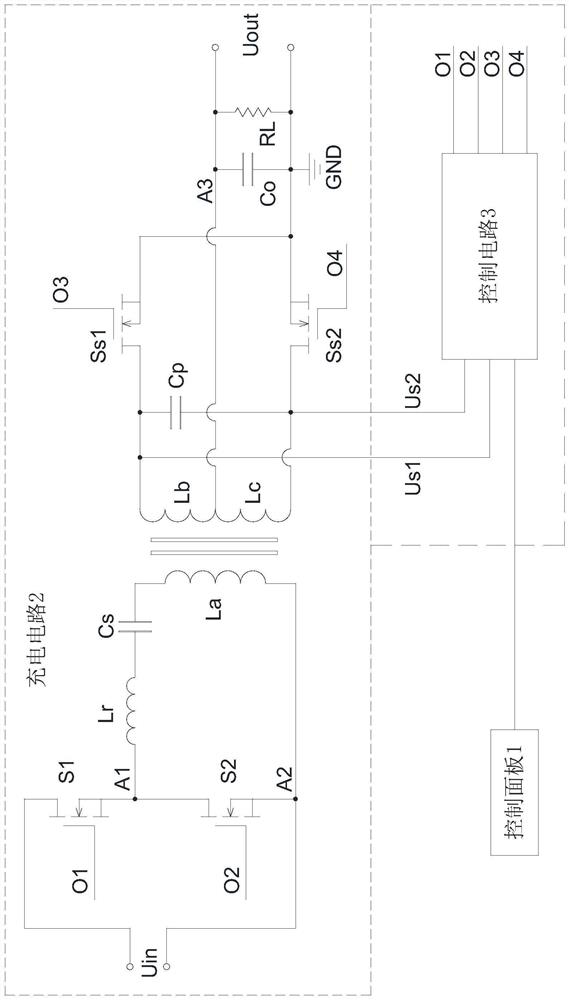

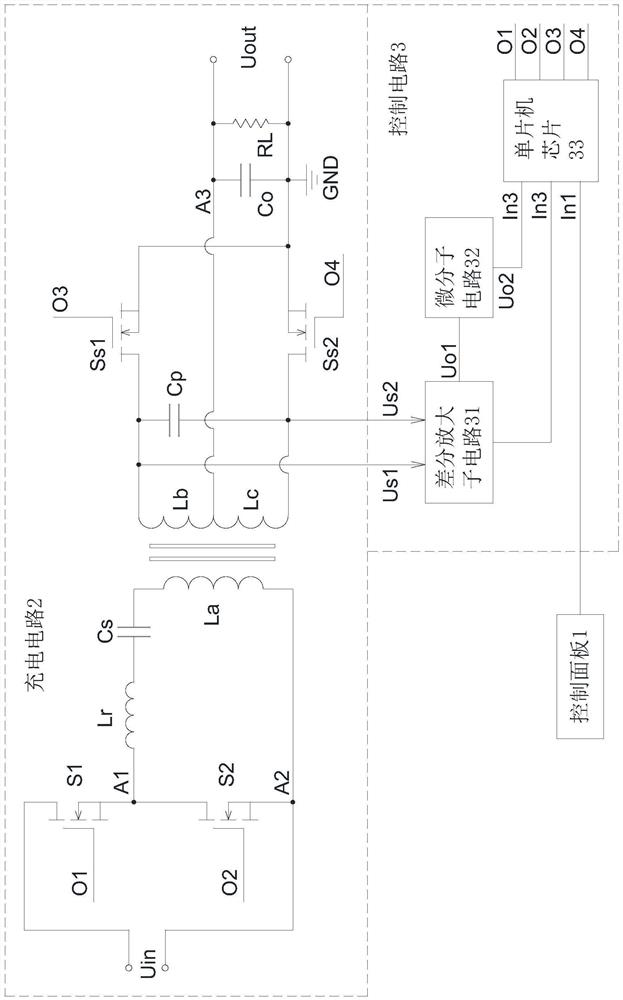

[0026] like Figure 1 to Figure 4 As shown, what this embodiment provides is a high-power battery charger, including a control panel 1, a charging circuit 2 and a control circuit 3, characterized in that:

[0027] The charging circuit 21 includes a voltage input terminal Uin, a transformer, and a voltage output terminal Uout. One end of the voltage input terminal Uin is connected to the D pole of the upper switching tube S1 of the half bridge, and the other end of the voltage input terminal Uin is connected to the lower switching tube S2 of the half bridge. The S pole of the switch tube S1 on the half bridge is connected to form the second node A2, the S pole of the switch tube S1 on the half bridge is connected to the D pole of the switch tube S2 on the half bridge to form the first node A1, and the first node A1 is connected to the second node A2 A2 is connected in series with the primary resonant inductor Lr, the primary resonant capacitor Cs and the primary coil La of the ...

Embodiment 2

[0037] like Figure 5 As shown, this embodiment provides a method for controlling a high-power battery charger, and the high-power battery charger is the high-power battery charger described in Embodiment 1, wherein the control method includes:

[0038] Step A, controlling the first output terminal and the second output terminal of the control circuit according to the signal sent by the control panel, so as to adjust the switching frequency of the upper switching tube S1 of the half bridge and the lower switching tube S2 of the half bridge;

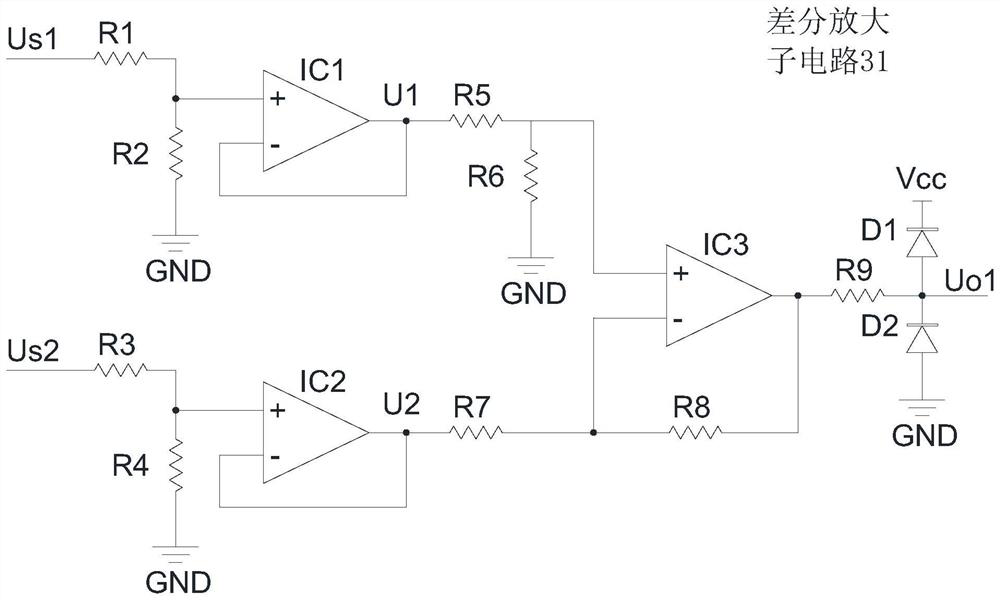

[0039] Step B, detecting the voltage values of the first synchronous rectification detection input terminal Us1 and the second synchronous rectification detection input terminal Us2 to obtain the synchronous rectification conduction value VCp;

[0040] Step C, when the synchronous rectification conduction value VCp is equal to the first preset value, the third output terminal of the control circuit outputs a high level, and the first re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com