Production method of anhydrous sodium sulfate and production equipment thereof

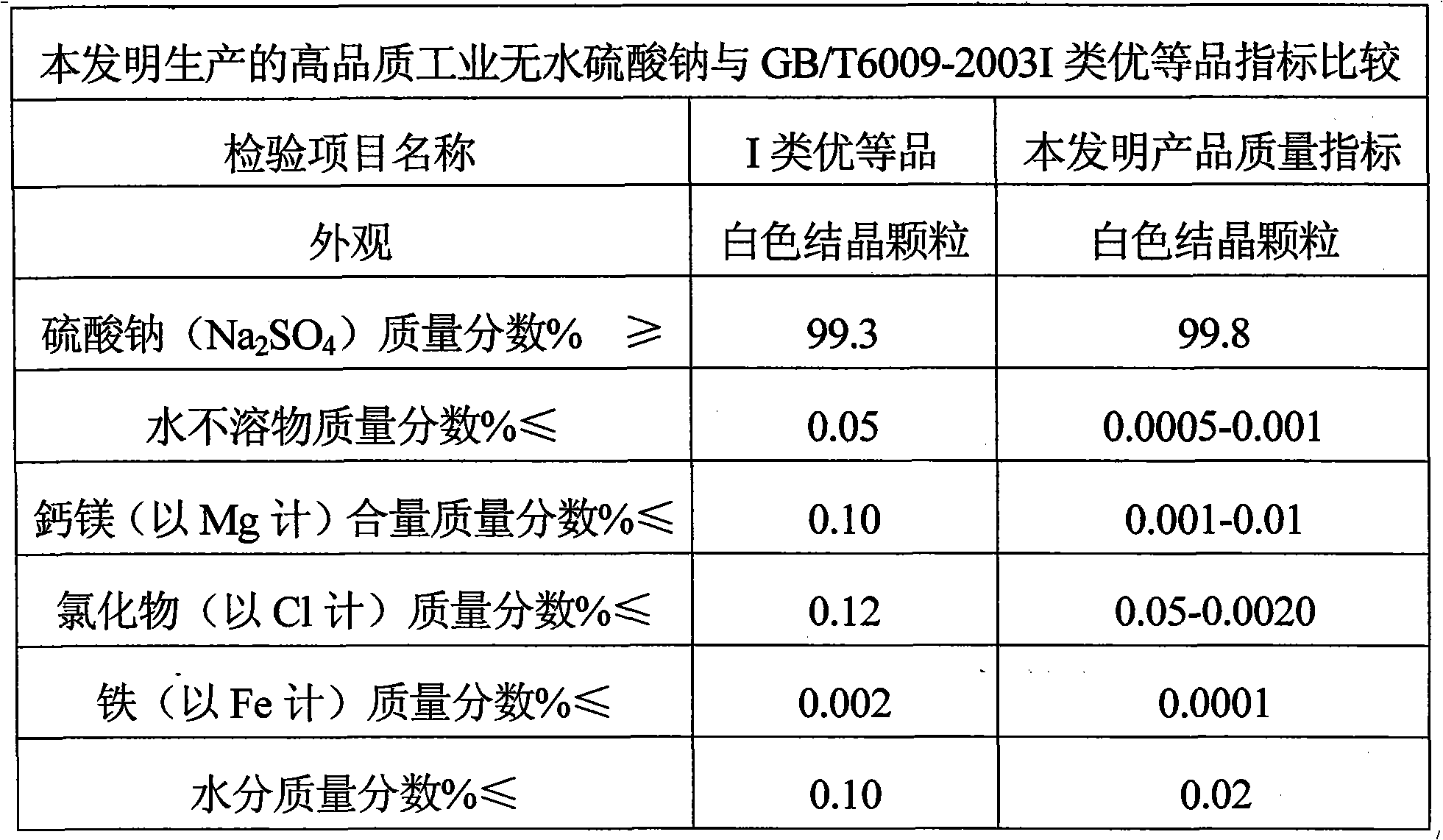

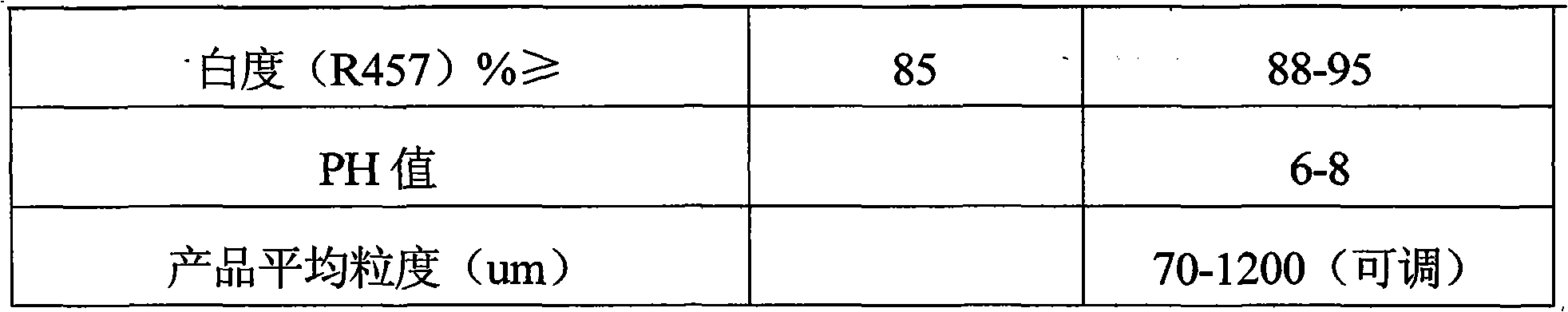

A technology of anhydrous sodium sulfate and production equipment, applied in the direction of alkali metal sulfite/sulfate dehydration, etc., can solve the problem that it is difficult to ensure that the pH value of anhydrous sodium sulfate is neutral, and the anhydrous sodium sulfate particles are difficult to reach developed countries. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

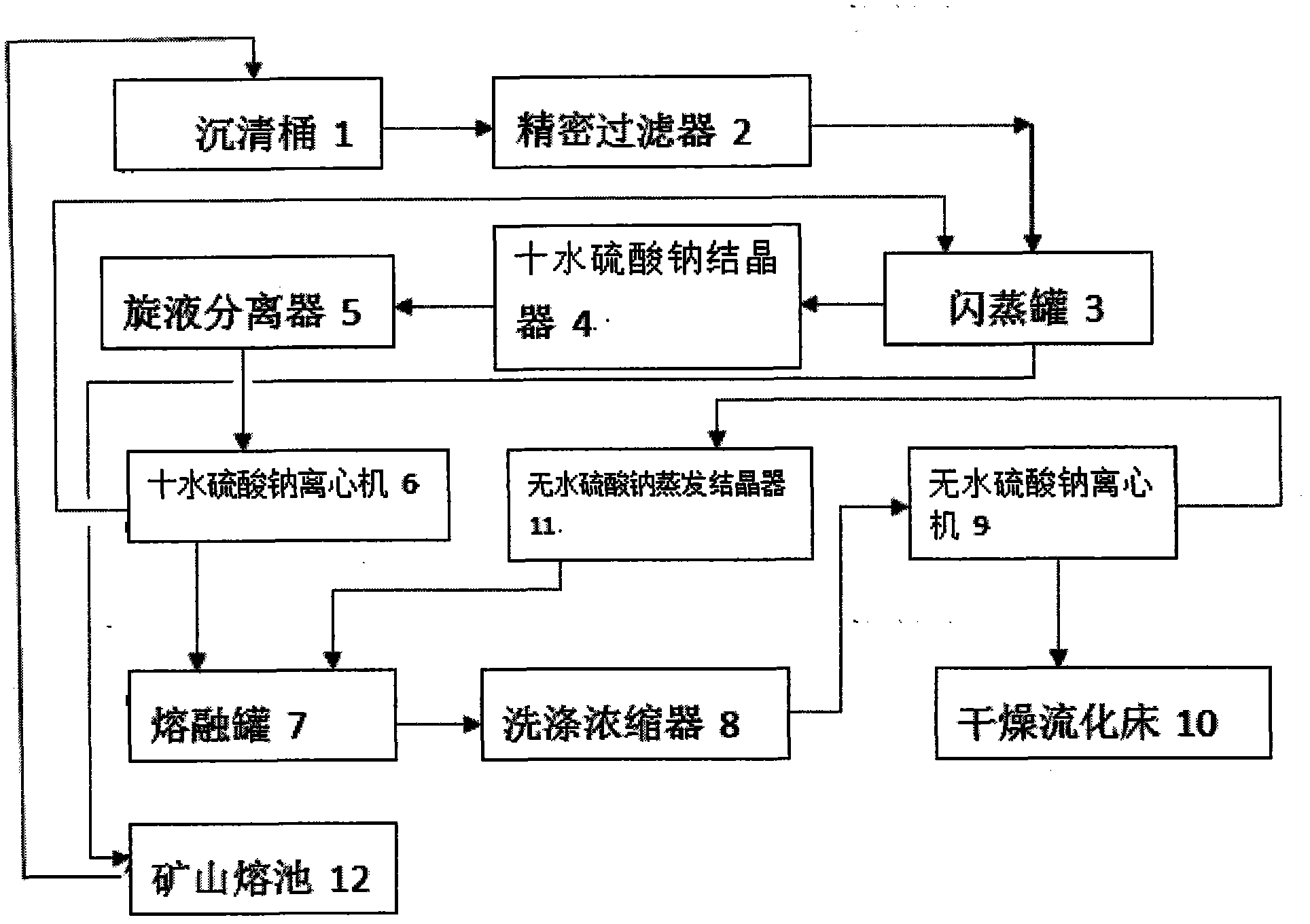

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are as follows:

[0022] The production method of anhydrous sodium sulfate of the present invention, comprises the steps:

[0023] (1) Purification of sodium sulfate aqueous solution (or nitric water for short)

[0024] The sodium sulfate aqueous solution obtained from mines or other methods is firstly cleaned to remove a large amount of impurities, and then the sodium sulfate aqueous solution is filtered with a precision filter to produce qualified sodium sulfate aqueous solution or refined nitric water for short, so that the mechanical impurities in the sodium sulfate aqueous solution The total amount of suspended solids is less than 10PPm.

[0025] (2) Preparation of sodium sulfate decahydrate

[0026] Sodium sulfate decahydrate is also called mirabilite or decahydrate salt. Its molecular formula is: Na2SO4.10H2O. Sodium sulfate decahydrate is obtained by saturated crystallization of sodium sulfate aqueous solution below 32.4°C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com