Presintering treatment process of glass batch and device thereof

A technology of glass batch materials and processing technology, applied in glass manufacturing equipment, glass production, manufacturing tools, etc., can solve the problems of increasing the difficulty of breaking, discontinuous production process, etc., to reduce energy consumption, increase single-line production, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

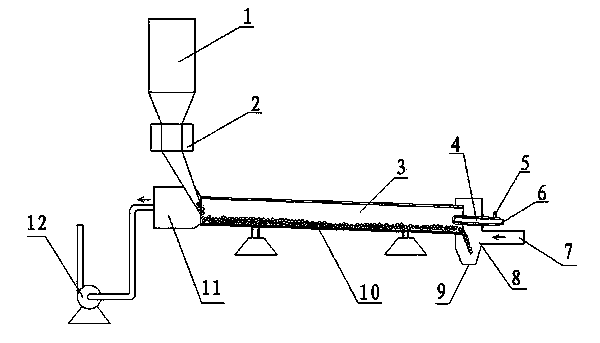

[0025] like figure 1 Show, a device that is decomposed by glass with carbonate melting kiln -rotary heating furnace, which includes a feed device 2. The rotary heating tube with the level of 3 ~ 12 ° incumbent 3. The kiln head sealing device 8 8, Kiln sealing device 11 and burner 4;

[0026] There is a storage compartment 1 at the upper end of the investment device 2, and the lower end is connected to the kiln tail seal device 11;

[0027] The high -end and low -end of the rotary heating cylinder 3 are connected with the kiln tail sealing device 11 and the kiln head sealing device 8 sealing.The sealing device 8 is equipped with flue gas entrance 7 and spherical granular export 9;

[0028] The burner 4 passed through the kiln head sealing device 8 into the rotary heating cylinder 3, with gas imports 5 and air import 6 on the burner 4.

[0029] The length of the rotary heating cylinder 3 is 10 ~ 50 meters, the inner diameter is 1.2 ~ 3.5 meters, the speed is 3 ~ 10 rpm / minutes, the ...

Embodiment 2

[0037] Unlike Example 1::

[0038] (1) The water glass that occupies 1.5WT%of the glass with ingredients is dissolved in the water that occupies 8WT.%of the glass and the ingredients, and then the above water glass solution is mixed into the glass and the material is mixed.The roller suppress it into a spherical material of 5 to 18mm.

[0039] (2) Add the spherical granules to the rotary heating furnace, pre -fever at 1180 ~ 1250 ° C, and add the densely tied spherical granules from the exit of the rotary heating furnace to the glass melting kiln.

[0040] Because the supplementary granular material is 5 ~ 18mm, the pre -fever and decomposition in the turning heating cylinder is about 1 hour.

[0041] The water glass in this embodiment can also be replaced with methyl cellulose.

Embodiment 3

[0043] Unlike Example 1::

[0044] (1) Solk the glass glass with 3WT%of the ingredients in the glass with the glass with the water (80-100 ° C) with the glass and the ingredients, and then mix the above water glass solution toThe roller with a semi -circular concave surface is used to suppress it into a spherical material of 8 ~ 25mm.

[0045] (2) Add the spherical granules to the rotary heating furnace, pre -burned at 1020 ~ 1150 ° C, and the densely tied spherical granules are added from the exit of the rotary heating furnace to the glass melting kiln.

[0046] Because the supplementary granular material is 8 ~ 25mm, the pre -fever and decomposition in the turning heating cylinder is about 1.5 hours.The device of the three groups of practical examples 1 in this embodiment is pre -burned at the same time.

[0047] The water glass in this embodiment can also be replaced with methyl cellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com