Glass batch presintering treatment technology

A technology of glass batch materials and processing technology, applied in glass production, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of discontinuous production process and increased difficulty of breaking, so as to increase single-line production, reduce energy consumption, and increase heat the effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

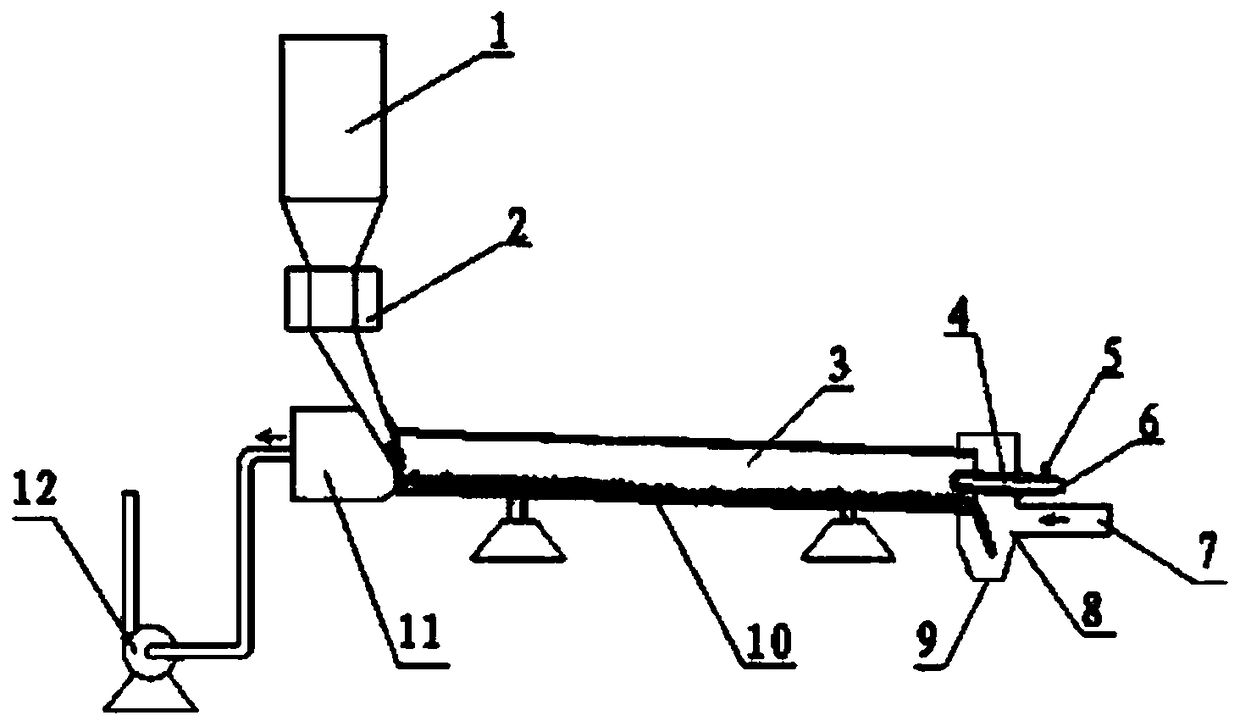

[0025] Such as figure 1 As shown, a device for decomposing glass batch materials outside a carbonate melting furnace - a rotary heating furnace, which includes a feeding device 2, a rotary heating cylinder 3 with an inclination angle of 3 to 12° from the horizontal, and a kiln head sealing device 8 , kiln tail sealing device 11 and burner 4;

[0026] The upper end of the feeding device 2 is provided with a storage bin 1, and the lower end is connected with the kiln tail sealing device 11;

[0027] The high end and the low end of the rotary heating cylinder 3 are respectively sealed and connected with the kiln tail sealing device 11 and the kiln head sealing device 8, and one end of the kiln tail sealing device 11 is connected with the inlet of the high-temperature induced draft fan 12, and the kiln head The sealing device 8 is provided with a flue gas inlet 7 and a spherical pellet outlet 9;

[0028] The burner 4 extends into the rotary heating cylinder 3 through the kiln he...

Embodiment 2

[0037] The difference with embodiment 1 is:

[0038] (1) Dissolve the water glass accounting for 1.5wt% of the glass batch in water accounting for 8wt.% of the glass batch, then mix the above-mentioned water glass solution into the glass batch, mix well, and use a semicircular concave surface on the surface It is pressed into spherical pellets of 5-18 mm by pair of rollers.

[0039] (2) Put the spherical pellets into the rotary heating furnace, pre-fire at 1180-1250° C., and feed the sintered and compacted spherical pellets into the glass melting furnace from the outlet of the rotary heating furnace.

[0040] Since the pellets compressed into a spherical shape are 5-18mm in size, the pre-calcination decomposition time in the rotary heating cylinder is about 1 hour.

[0041] Water glass described in the present embodiment can also be replaced with methyl cellulose.

Embodiment 3

[0043] The difference with embodiment 1 is:

[0044] (1) Dissolve water glass accounting for 3wt% of the glass batch in hot water (80-100°C) accounting for 7wt.% of the glass batch, then add the above-mentioned water glass solution into the glass batch, mix well, It is pressed into spherical pellets of 8-25 mm by means of a pair of rollers with a semicircular concave surface on the surface.

[0045] (2) Put the spherical pellets into the rotary heating furnace, pre-fire at 1020-1150° C., and feed the sintered and compacted spherical pellets into the glass melting furnace from the outlet of the rotary heating furnace.

[0046] Since the pellets compressed into a spherical shape are 8-25mm in size, the pre-calcination decomposition time in the rotary heating drum is about 1.5 hours. In this embodiment, three sets of devices described in Embodiment 1 are used to simultaneously pre-fire the glass batch.

[0047] Water glass described in the present embodiment can also be replaced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com