Method and apparatus for treating high-temperature slag

A processing method and processing device technology, applied in the direction of processing discharged materials, furnaces, furnace components, etc., can solve the problems of low cooling efficiency, long time, huge equipment and cost, etc., to achieve improved recovery efficiency, high separation efficiency, The effect of cheap equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

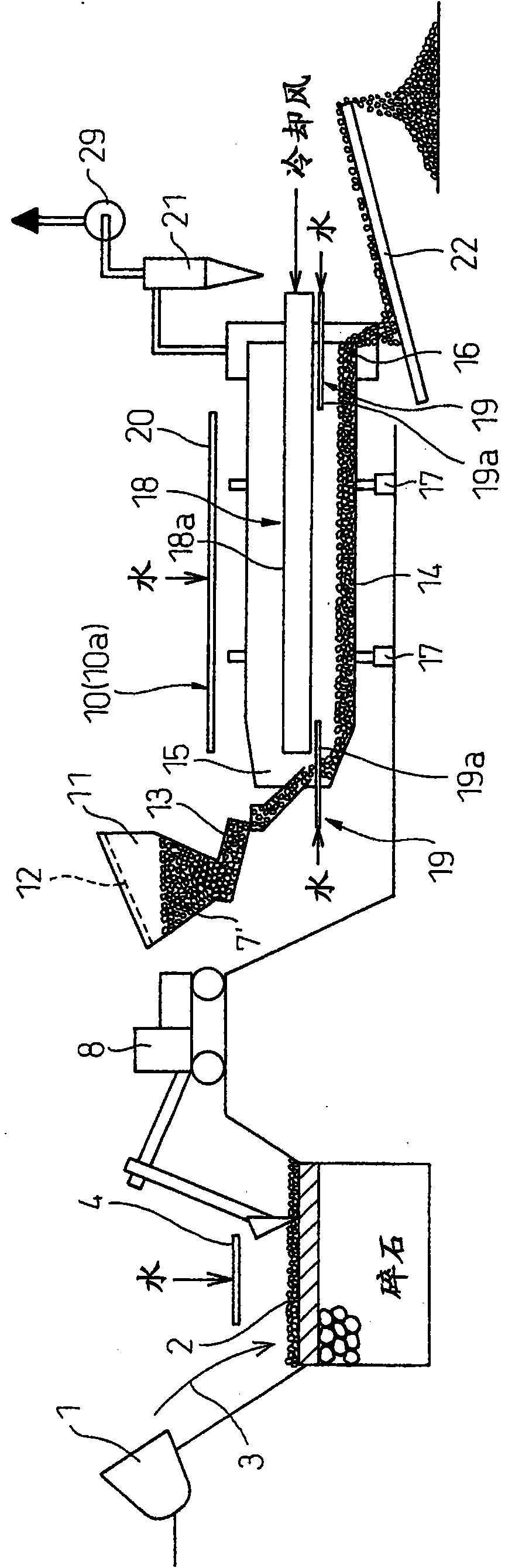

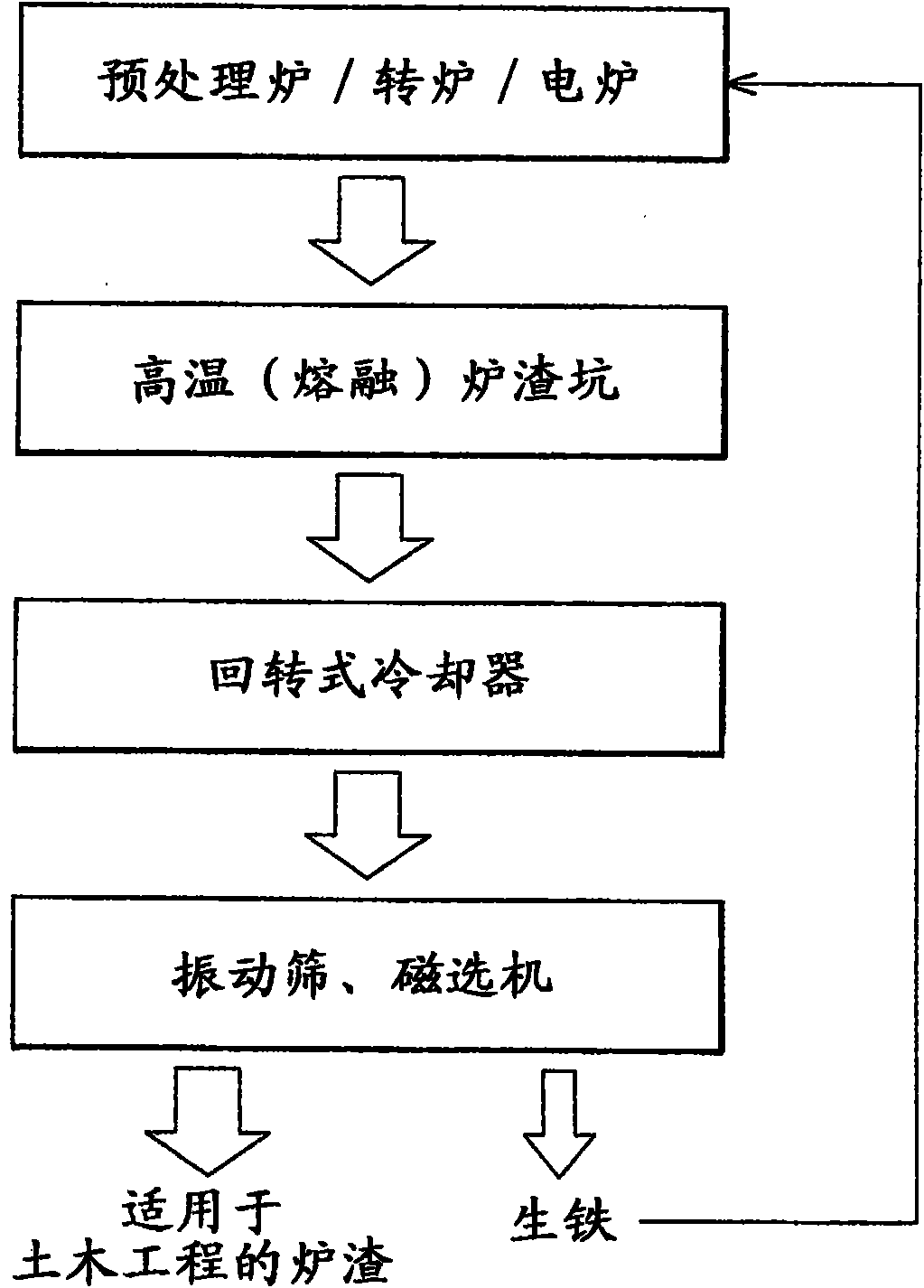

[0113] About 20 tons of molten iron pretreatment slag containing CaO at about 1300 °C generated when CaO powder was blown in for dephosphorization and desulfurization of molten iron was transferred to such as figure 1 The shown pit covered with steel slag was stirred to a uniform thickness, and then water was sprayed on the surface to cool down to 1000°C once. The thickness of the slag layer is 0.25 m and its area is about 6 m x 5 m. The cooling water evaporates instantly without producing free water.

[0114] The slag which has been cooled once in this way is put into the hopper, and the large pieces of pig iron are separated and removed by a grid screen, and thereafter, it is supplied to a slag with a diameter of about 2m and a length of about 8m. figure 1 The rotary cooler shown in , with secondary cooling. The slag temperature at the slag charging port of the rotary cooler was 850°C. Inject 142m to the slag 3 / hour of cooling air, air cooling inside the rotary coole...

Embodiment 2

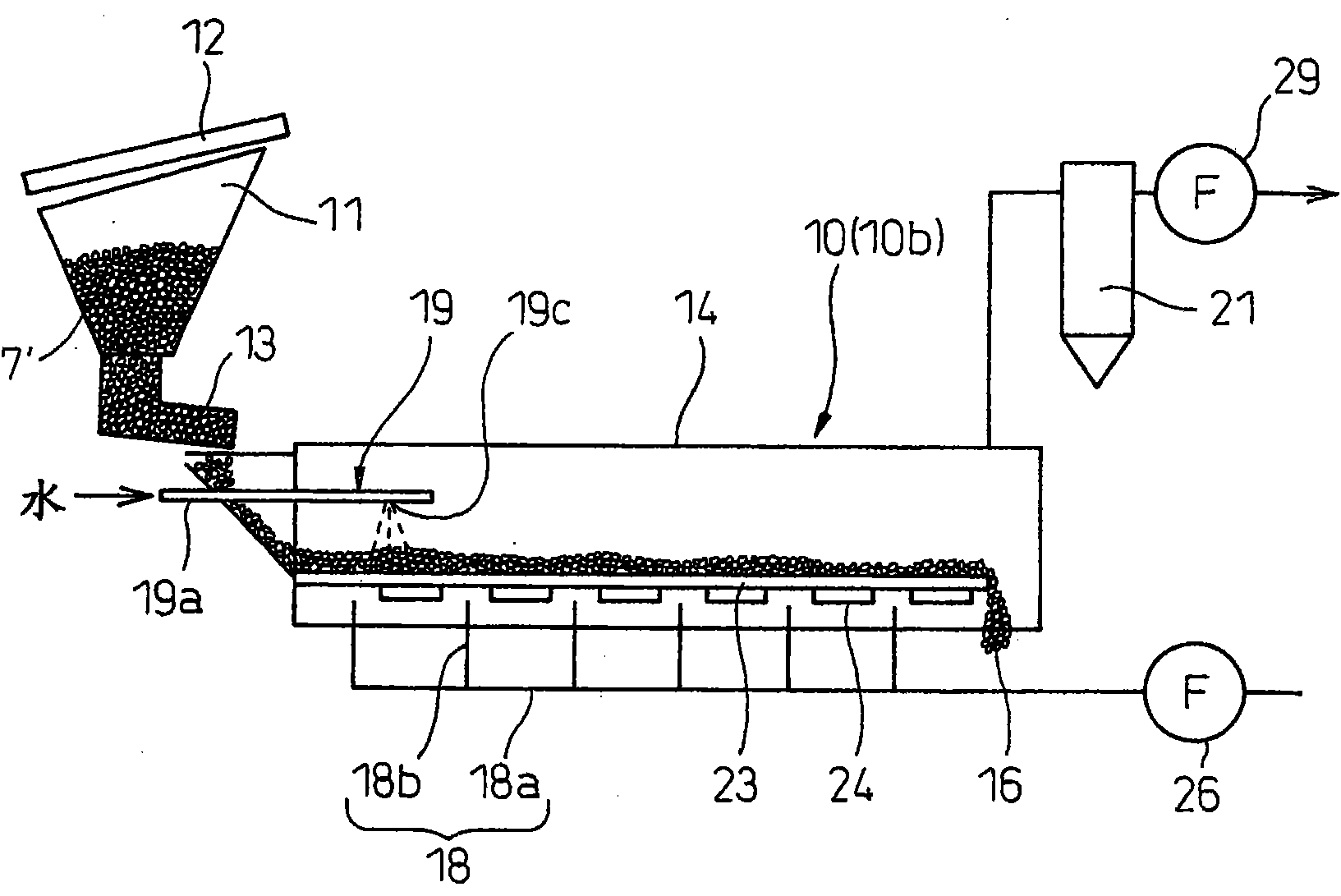

[0119] The present invention was carried out using 1,000 tons of steelmaking slag discharged from the steelmaking process. The temperature of the slag discharged from the furnace is about 1400°C in a molten state, and it is Figure 4 The shown cooling pit was allowed to stand for 20 minutes to solidify, and instead of spraying cooling water as in the past, a 3.0m 3 / hour, 5 minutes of water spray cooling. Next, the slag was excavated by a power excavator and put into a rotary cooler. The feeding rate is 10 tons / hour, and the slag temperature at the time of feeding is about 1000°C.

[0120] The casing (shell) of the rotary cooler was rotated at 5 rpm, the residence time of the slag inside was 20 minutes, and 400 m of slag was supplied to the inside of the casing (shell). 3 / min of cooling air and 5m 3 / hour of cooling water. No free water was produced in this water cooling. Formed inside the case (shell) as Figure 5 As shown in the protrusion, the slag is crushed by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com