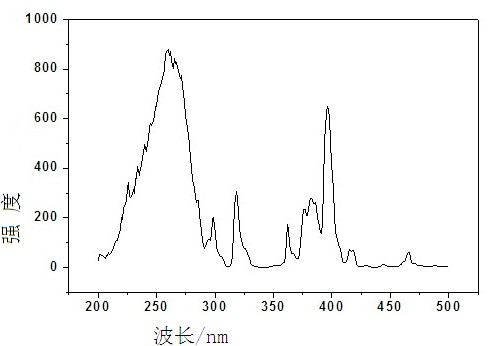

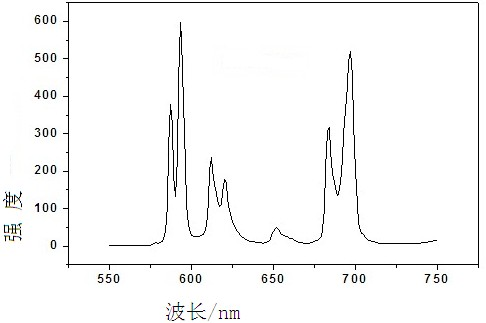

Phosphor excited at ultraviolet 250-290 nm and near ultraviolet 396 nm and preparation method thereof

A phosphor and near-ultraviolet technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of lack of and can not effectively improve the color rendering index of energy-saving lamps and white LEDs assembled, and achieves simple preparation method, excitation Wide wavelength range and good luminous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

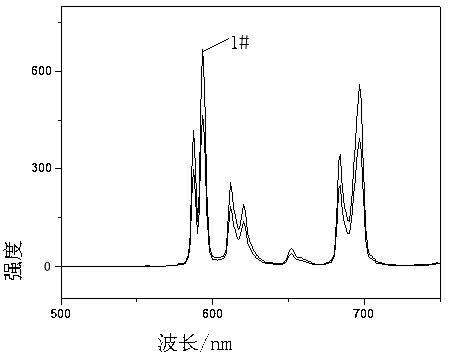

Embodiment 1

[0026] Weigh Li according to the molar ratio Li:Zn:P:Eu=1.09:0.82:1:0.09 2 CO 3 , ZnO, (NH 4 ) 2 HPO 4 , Eu 2 o 3 , the above raw materials are all analytically pure, after mixing the above raw materials evenly, put them into an alumina crucible and place them in a muffle furnace for roasting in an air atmosphere at a temperature of 500°C and keep them warm for 5 hours; grind them after cooling, and then put them in an air atmosphere Baking at 1000°C for 3 hours. The resulting product is crushed, washed with water to remove impurities, and dried to obtain the chemical composition of Li 1.09 Zn 0.82 PO 4 :0.09Eu 3+ sample.

Embodiment 2

[0028] Weigh Li according to the molar ratio Li:Zn:P:Eu=1:0.91:1:0.09 2 CO 3 , ZnO, (NH 4 ) 2 HPO 4 , Eu 2 o 3 , the above raw materials are all analytically pure, after mixing the above raw materials evenly, put them into an alumina crucible and place them in a muffle furnace for roasting in an air atmosphere at a temperature of 500°C and keep them warm for 5 hours; grind them after cooling, and then put them in an air atmosphere Baking at 1000°C for 3 hours. The obtained product is crushed, washed with water to remove impurities, and dried to obtain the chemical composition of LiZn 0.91 PO 4 :0.09Eu 3+ sample.

Embodiment 3

[0030] Weigh Li according to the molar ratio Li: Zn: P: Eu=1.11:0.78:1:0.11 2 CO 3 , ZnO, (NH 4 ) 2 HPO 4 , Eu 2 o 3 , the above raw materials are all analytically pure, after mixing the above raw materials evenly, put them into an alumina crucible and place them in a muffle furnace for roasting in an air atmosphere at a temperature of 500°C and keep them warm for 5 hours; grind them after cooling, and then put them in an air atmosphere Baking at 1000°C for 3 hours. The resulting product is crushed, washed with water to remove impurities, and dried to obtain the chemical composition of Li 1.11 Zn 0.78 PO 4 :0.11Eu 3+ sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com