Novel combined soft water closed circulation cooling system

A circulating cooling system and soft water sealing technology, applied in cooling devices, etc., can solve the problems of uneconomical investment and operating costs, unreasonable configuration of combined soft water closed circulating cooling system, and large water volume in subsystems, etc., to reduce the number of pipelines , Reduced operating costs, the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

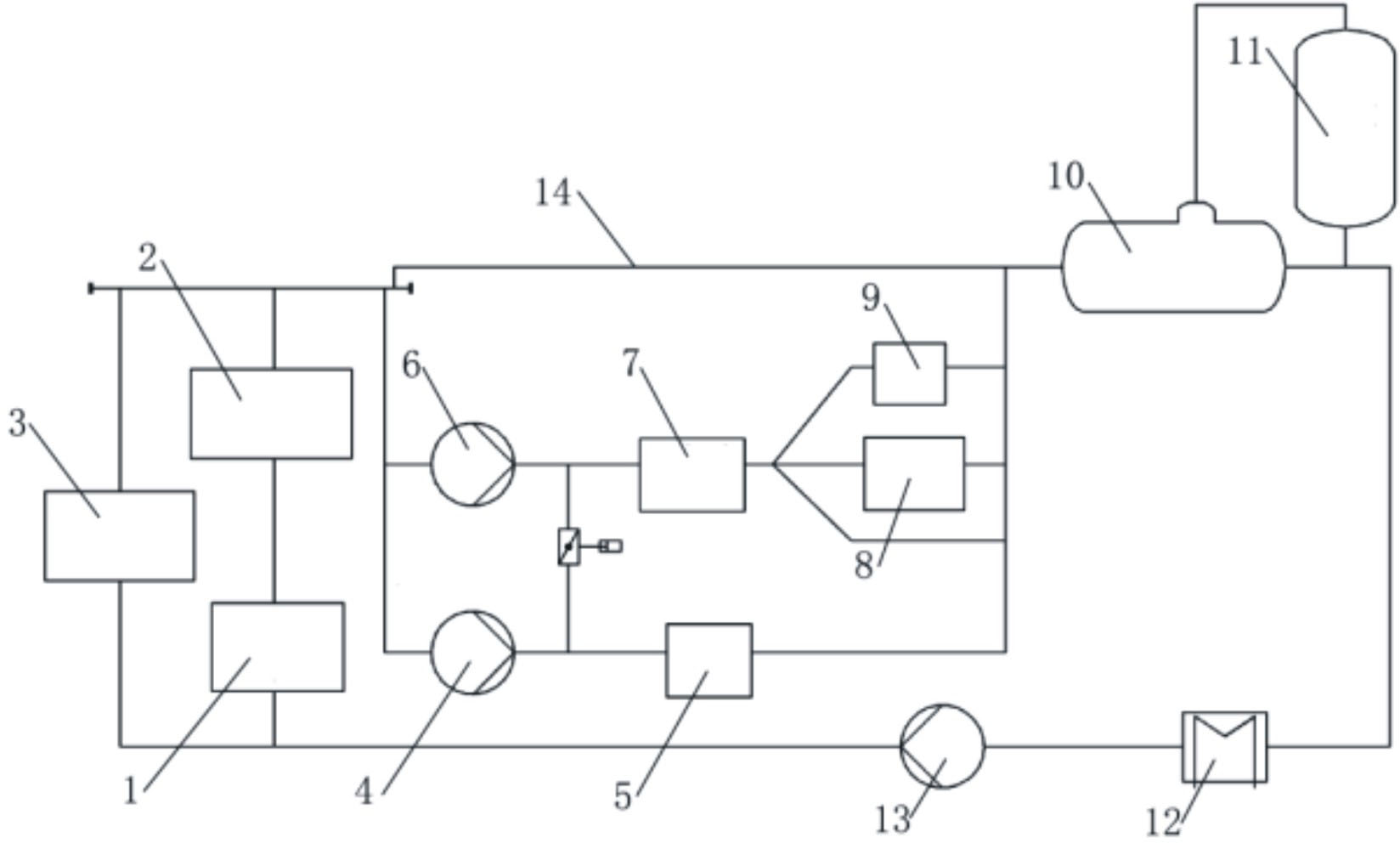

[0012] Embodiment one, as attached figure 1 As shown, the soft water pressurized by the main water supply pump group 13 is divided into two parts in front of the furnace, a part of the furnace bottom water cooling pipe 1 and stave serpentine pipe 2 in series are cooled, and a part of the cooling stave direct cooling pipe 3 is cooled. The water enters the stave return water main circulation pipe, and the soft water coming out of the stave return water general circulation pipe is divided into three parts, one part can directly enter the degassing tank 10 through the bypass shunt pipe 14, and the other part passes through the hot air valve booster pump group 4 The pressurization is used for the hot air valve 5; the other part is pressurized by the booster pump group 6 of the small tuyere set, and is used for the small tuyere 7. After cooling the soft water of the small tuyere 7, it is supplied to the parallel tuyere middle set 8 and the direct blowing pipe. 9 use; these two parts...

Embodiment 2

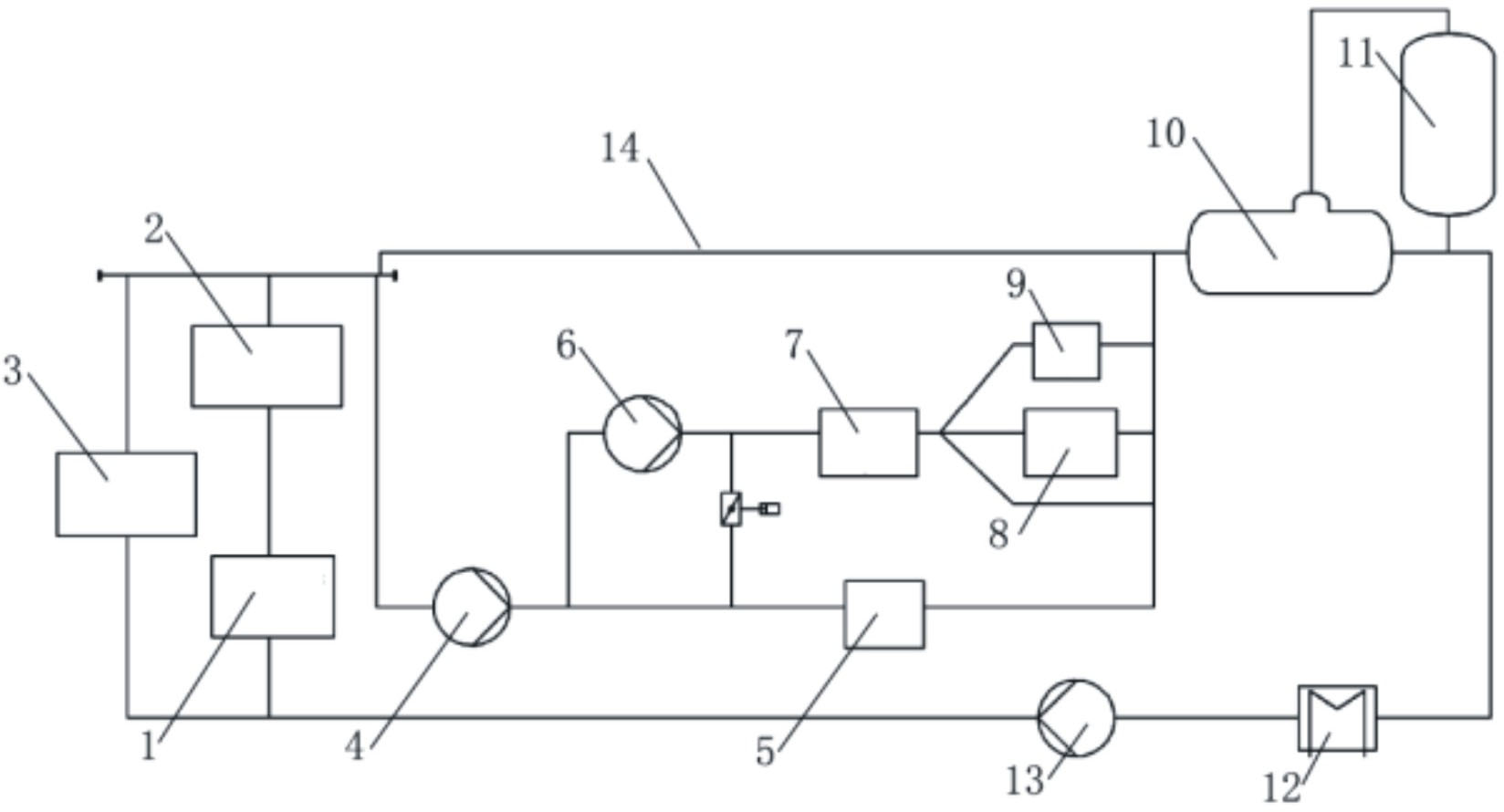

[0014] Embodiment two, as attached figure 2 As shown, the soft water pressurized by the main water supply pump group 13 is divided into two parts in front of the furnace, a part of the furnace bottom water cooling pipe 1 and stave serpentine pipe 2 in series are cooled, and a part of the cooling stave direct cooling pipe 3 is cooled. The water enters the stave return water main circulation pipe, and the soft water coming out of the stave return water general circulation pipe is divided into three parts, one part can directly enter the degassing tank 10 through the bypass shunt pipe 14, and the other part passes through the hot air valve booster pump group 4 Supercharging is supplied to the parallel hot air valve 5 and the small tuyere booster pump group 6. The soft water pressurized by the hot air valve booster pump group 4 is pressurized in series by the tuyere small booster pump group 6 and then supplied to the tuyere small set 7. After cooling the soft water in the tuyere ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com