Non-woven online treating device

A non-woven, spinning machine technology, applied in the processing of textile materials, liquid/gas/vapor textile material processing, textiles and papermaking, etc., can solve the problems of complex structure, high energy consumption and high production cost, and achieve simplification Complex structure, good drying effect, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

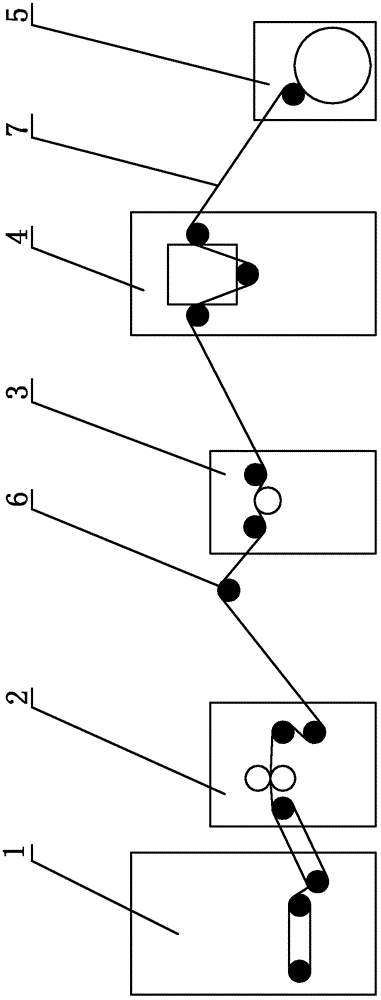

[0027] Such as figure 1 The device for on-line processing of non-woven fabrics shown includes a spinning machine 1, a hot rolling mill 2, a liquid filling machine 3, a drying machine 4 and a winding machine 5 arranged in sequence. in:

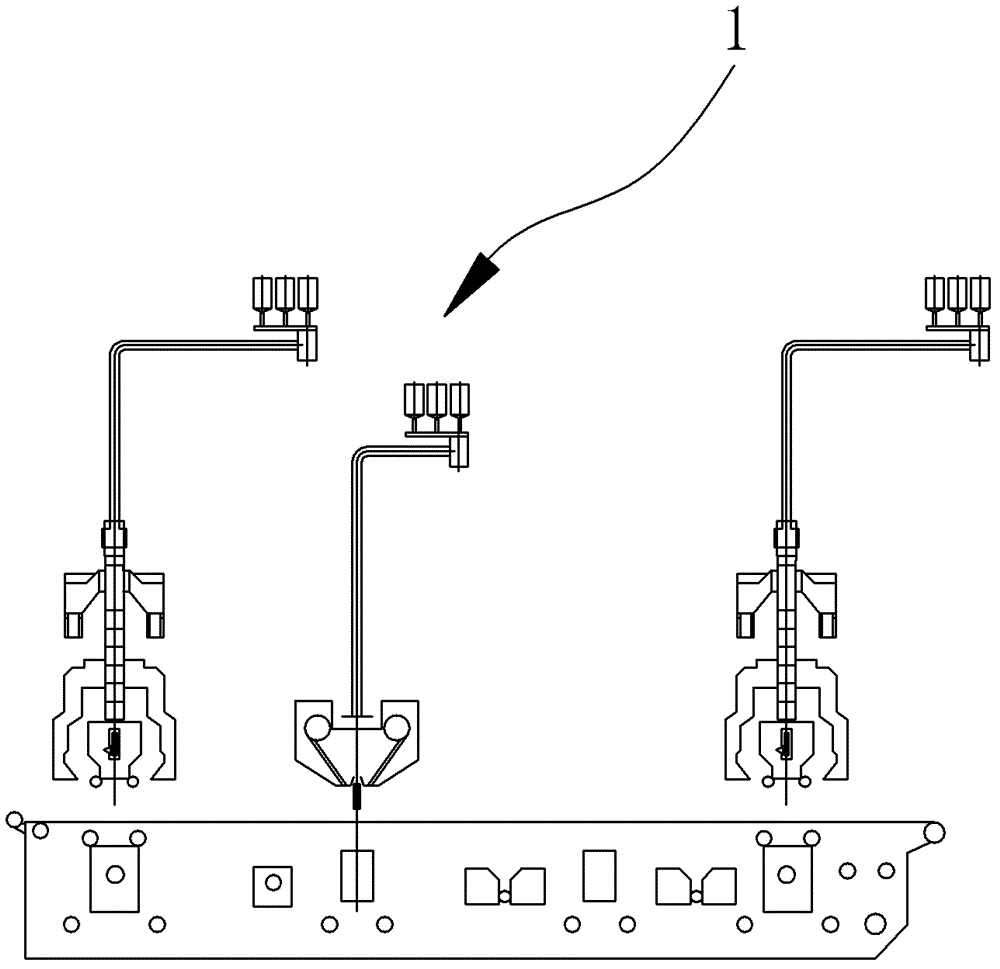

[0028] Spinning machine 1, hot-rolling mill 2 adopt existing spinning machine and hot-rolling mill on the market, and its model can be selected according to actual needs, such as figure 2 shown.

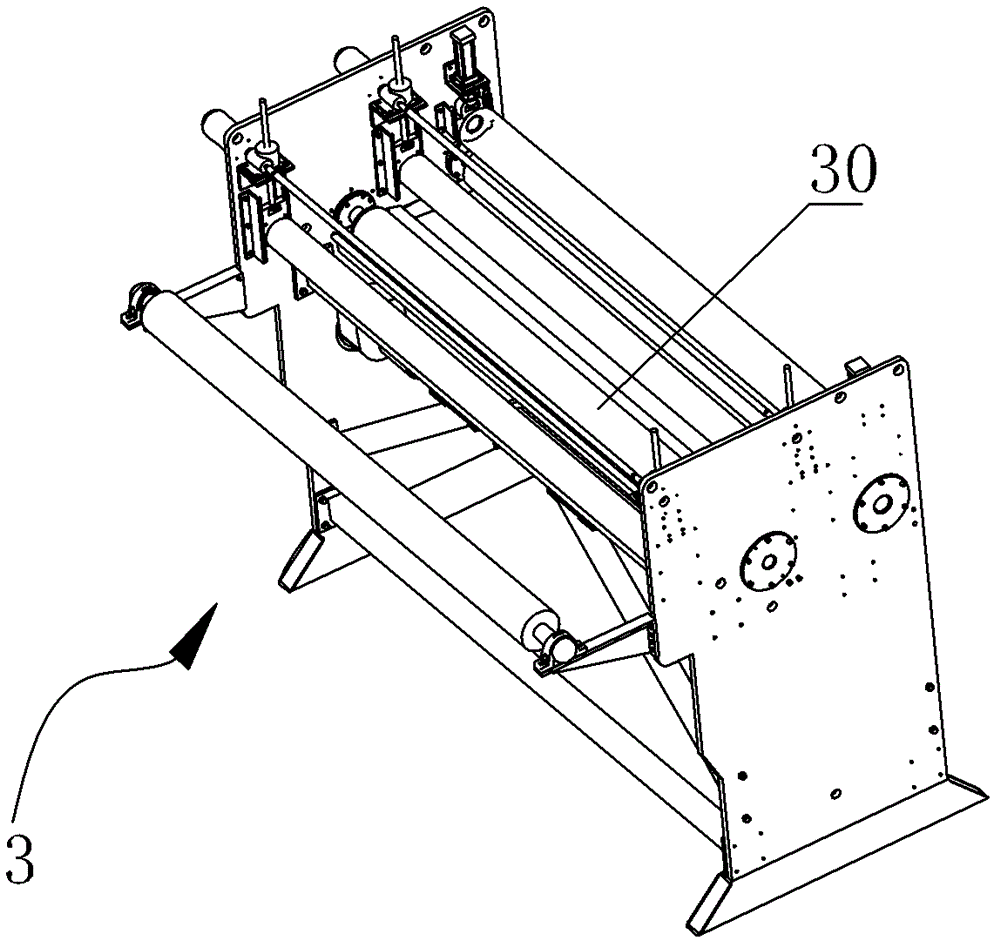

[0029] Such as image 3 , 4 As shown: the liquid loading machine 3 is provided with a coating roller 30, and a liquid tank 31 is provided under the coating roller 30, and the auxiliary agent is placed in the liquid tank 31, and the coating roller 30 can be partly immersed in the auxiliary agent. One or more liquid level columns 32 are arranged on the bottom surface of the liquid tank 31, and an opening 33 is opened on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com