Mixing device used on asphalt road surface site heat regeneration compound mixer

A technology of asphalt pavement and remixing machine, which is applied in road repair, roads, roads, etc. It can solve the problems of inability to decompose blocky old materials, difficulty in cleaning, uneven mixing of asphalt mixture, etc., to achieve cleaning automation, Save energy and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

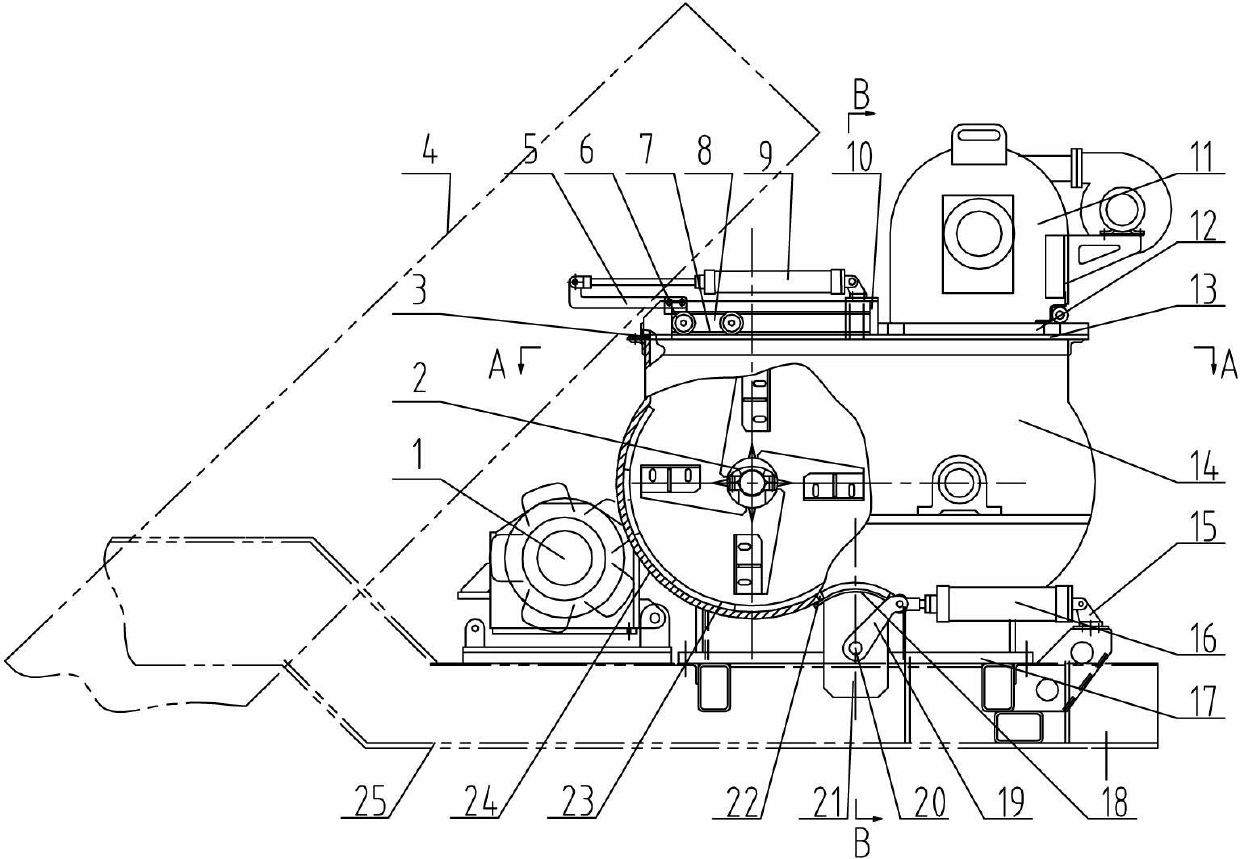

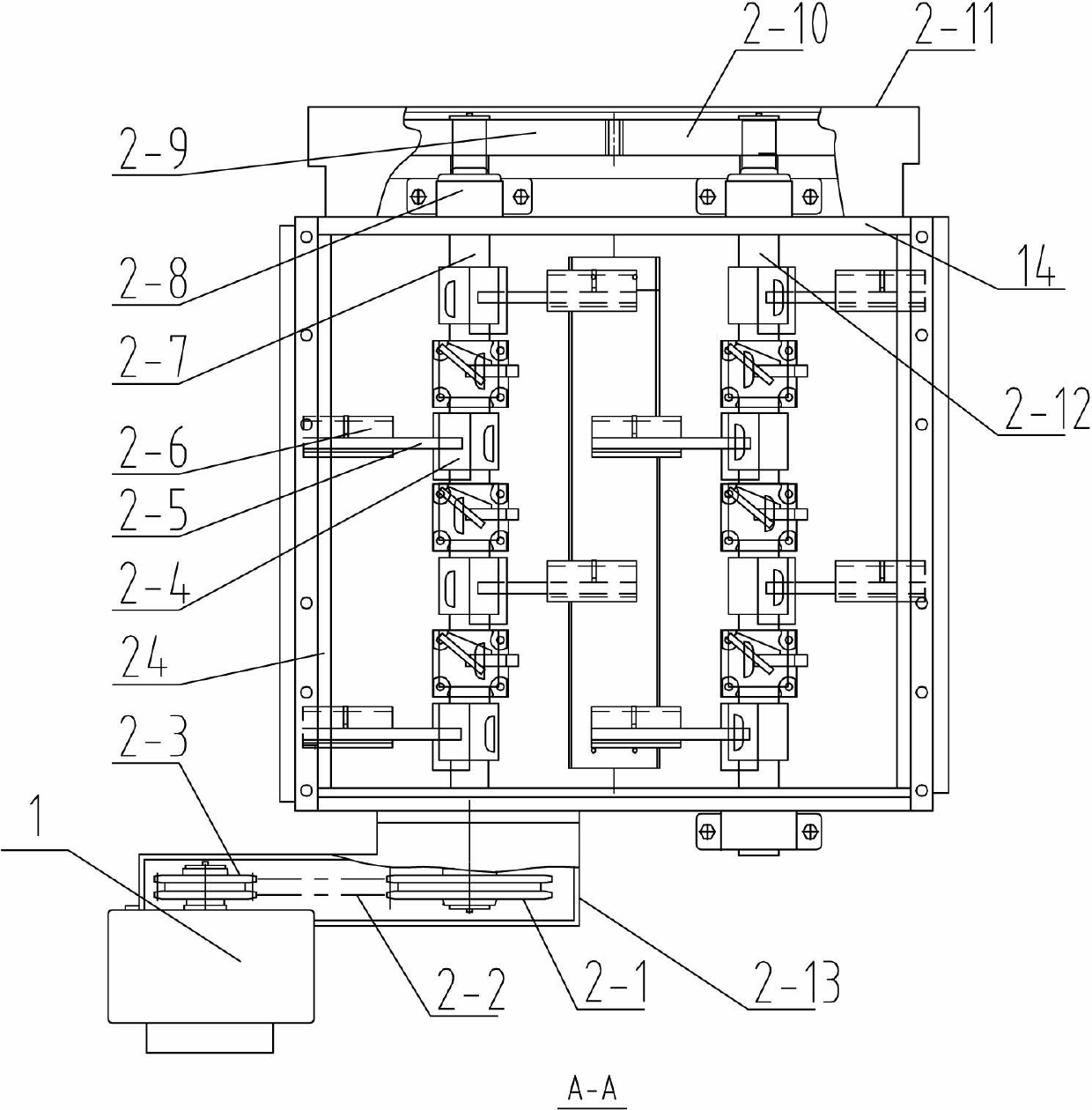

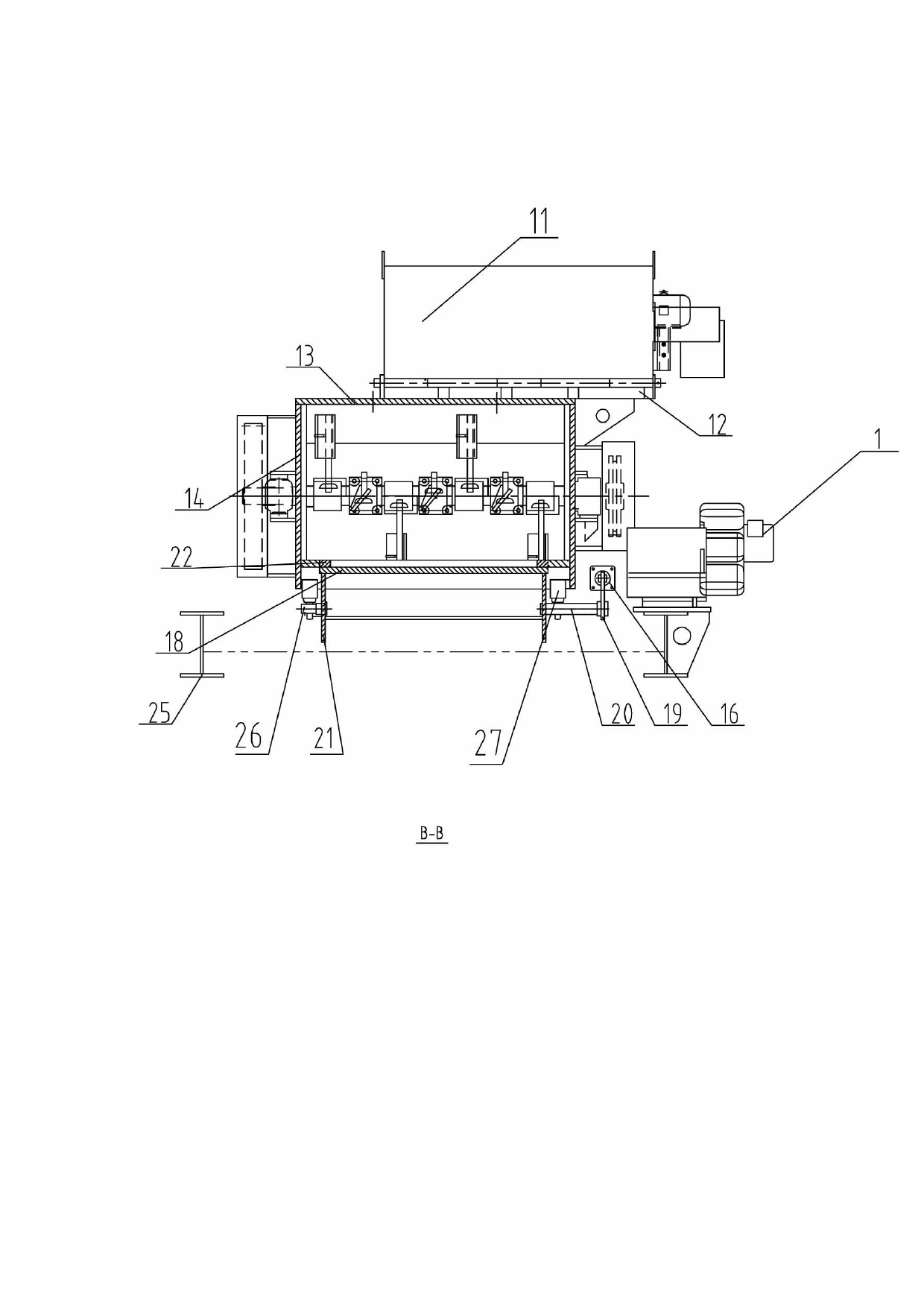

[0038] Such as figure 1 As shown, the mixing device used on the in-situ hot regeneration remixer for asphalt pavement of the present invention includes a hydraulic motor 1 connected with a hydraulic pump station on the vehicle frame 25, and a hot air motor 1 connected with a diesel tank on the vehicle frame 25. The heating furnace 11, the gas path interface connected with the air pump group on the vehicle frame 25, the mixing box arranged on the tail of the vehicle frame 25, the mixture agitator 2 arranged in the mixing box, and the hydraulic pressure The control device connected to the motor 1 and the hot air heating furnace 11 and the temperature detector connected to the control device are characterized in that the mixing box is composed of two box circles with the same radius, the same length, and symmetrical bottom connections. Arc-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com