Biomass pyrolysis device for laboratory

A technology for biomass pyrolysis and laboratory use, applied in the field of laboratory biomass pyrolysis devices, can solve problems such as low reaction efficiency, uneven temperature, complex structure, etc., achieve uniform material temperature, simple device structure, and high energy efficiency. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

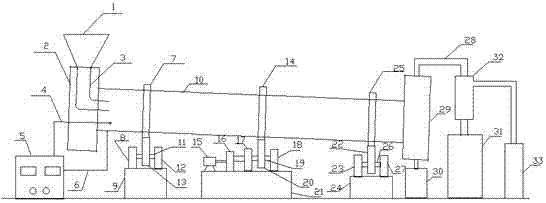

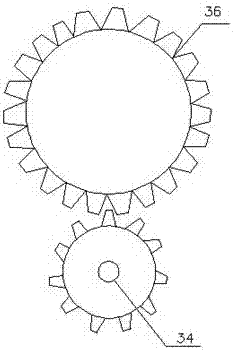

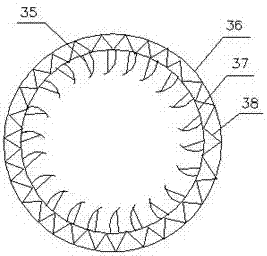

[0015] Embodiment 1: as Figure 1-3 As shown, a laboratory biomass pyrolysis device includes a feed hopper 1, a front sealing cover 2, a feed pipe 3, a thermocouple 4, a temperature controller 5, an electric wire 6, a large gear I7, a support frame I8, Platform Ⅰ9, drum 10, shaft Ⅰ11, support frame Ⅱ12, left support wheel 13, large gear Ⅱ14, motor 15, gearbox 16, support frame Ⅲ17, support frame Ⅳ18, rotating shaft 19, drive wheel 20, platform Ⅱ21, right support Wheel 22, support frame Ⅴ23, platform Ⅲ24, gear wheel Ⅲ25, shaft Ⅱ26, support frame Ⅵ27, outlet pipe 28, rear sealing cover 29, solid product tank 30, liquid product tank 31, water cooling pipe 32, gas product tank 33, round Hole 34, supporting plate 35 and heating resistance wire 38;

[0016] The feed hopper 1 is connected to the feed pipe 3, and the feed pipe 3 extends into the drum 10 through the front sealing cover 2, the front sealing cover 2 is fixed, and is sealed with one end of the drum 10; the rear sealing c...

Embodiment 2

[0020] Embodiment 2: as Figure 1-3 As shown, a laboratory biomass pyrolysis device includes a feed hopper 1, a front sealing cover 2, a feed pipe 3, a thermocouple 4, a temperature controller 5, an electric wire 6, a large gear I7, a support frame I8, Platform Ⅰ9, drum 10, shaft Ⅰ11, support frame Ⅱ12, left support wheel 13, large gear Ⅱ14, motor 15, gearbox 16, support frame Ⅲ17, support frame Ⅳ18, rotating shaft 19, drive wheel 20, platform Ⅱ21, right support Wheel 22, support frame Ⅴ23, platform Ⅲ24, gear wheel Ⅲ25, shaft Ⅱ26, support frame Ⅵ27, outlet pipe 28, rear sealing cover 29, solid product tank 30, liquid product tank 31, water cooling pipe 32, gas product tank 33, round Hole 34, supporting plate 35 and heating resistance wire 38;

[0021] The feed hopper 1 is connected to the feed pipe 3, and the feed pipe 3 extends into the drum 10 through the front sealing cover 2, the front sealing cover 2 is fixed, and is sealed with one end of the drum 10; the rear sealing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com