Efficient energy-saving aluminum alloy bar electromagnetic heating furnace

An electromagnetic heating furnace, high-efficiency and energy-saving technology, applied in the field of heating furnaces, can solve the problems of high energy consumption, uneven temperature of aluminum alloy rod materials, product rupture and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

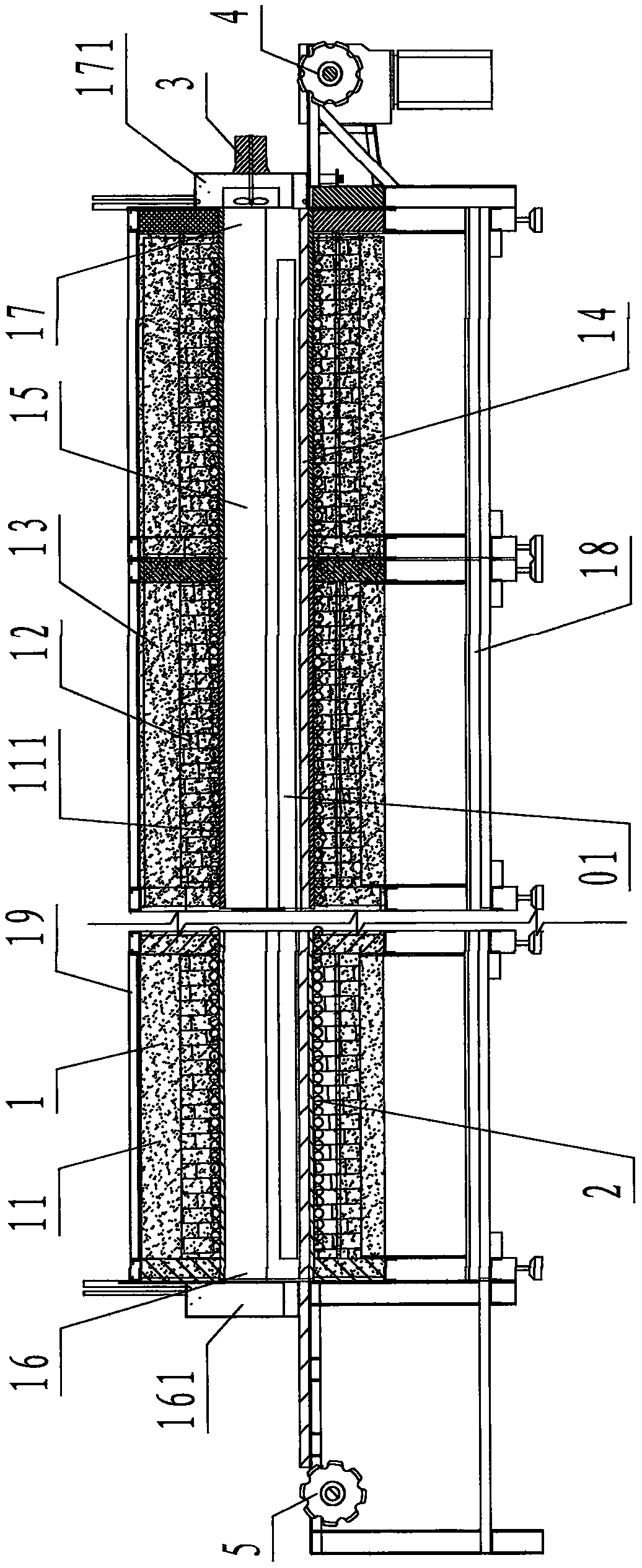

[0023] refer to figure 1, a high-efficiency energy-saving aluminum alloy rod electromagnetic heating furnace of the present invention includes a furnace body 1, an electromagnetic coil 2, a fan 3, a feeder 4 and a discharger 5, wherein: the furnace body 1 is hollow, left and right The two ends are open, the cross-section is back-shaped, and the rectangular tubular member is called the furnace wall 11, the inner cavity of the furnace body 1 is called the furnace cavity 15, and the openings at the left and right ends of the furnace body 1 are called The left furnace mouth 16 and the right furnace mouth 17 are respectively provided with a left furnace door 161 and a right furnace door 171 which can open and close the left furnace mouth 16 and the right furnace mouth 17. ;

[0024] The furnace wall 11 is composed of a refractory groove 111, a refractory brick 12, a rock wool insulation layer 13 and a furnace cover 19 from the inside to the outside. The refractory groove 111 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com