Continuous-blowdown drainage heat recovery system of boiler

A heat recovery and water-repelling technology, which is applied in steam boilers, steam boiler accessories, steam boiler components, etc., can solve the problems of waste of hydropower resources, affecting the safe operation of power plants, etc., and achieve the goal of reducing steam exhaust and slowing down scaling and plugging pipes Possibility, simple effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

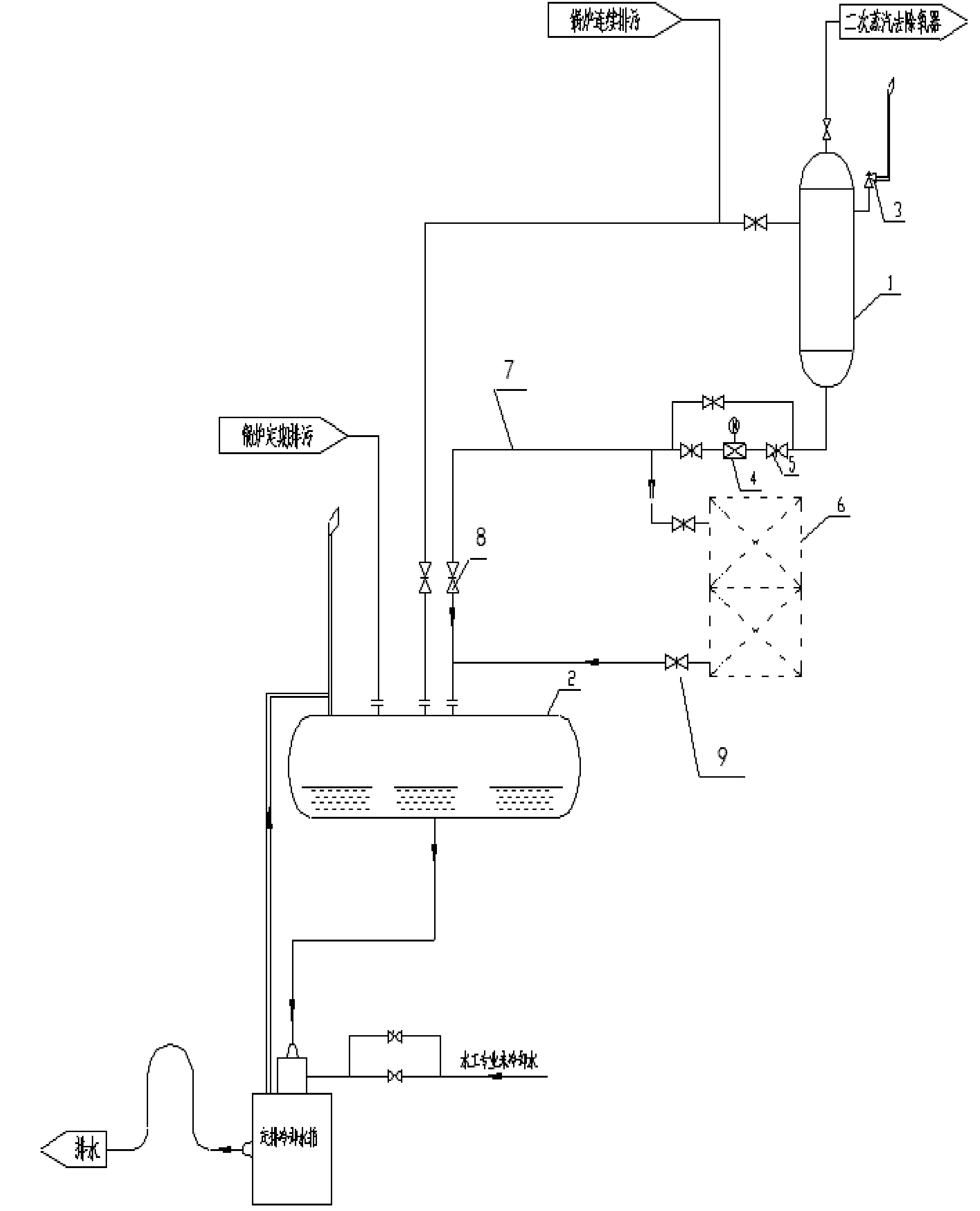

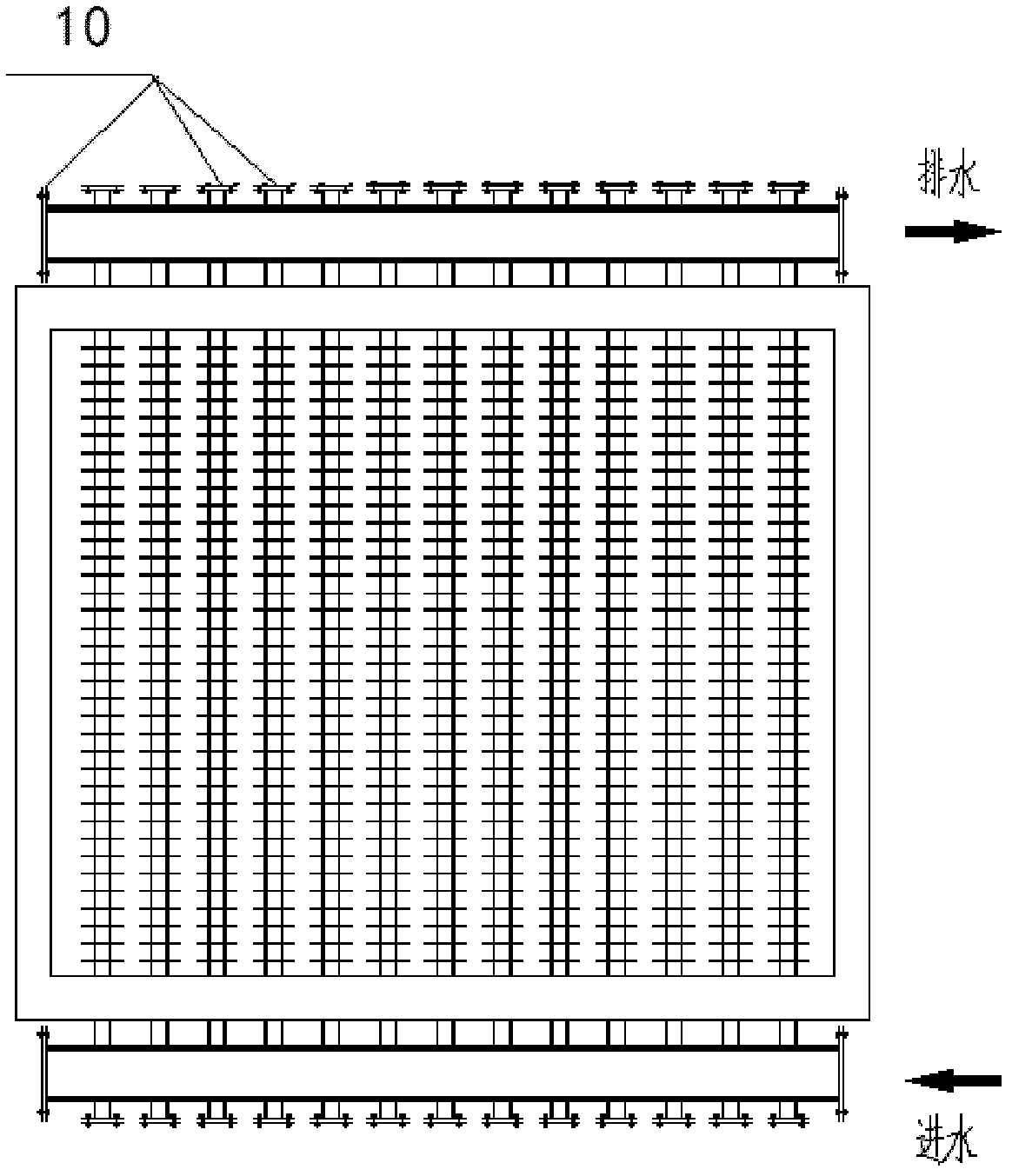

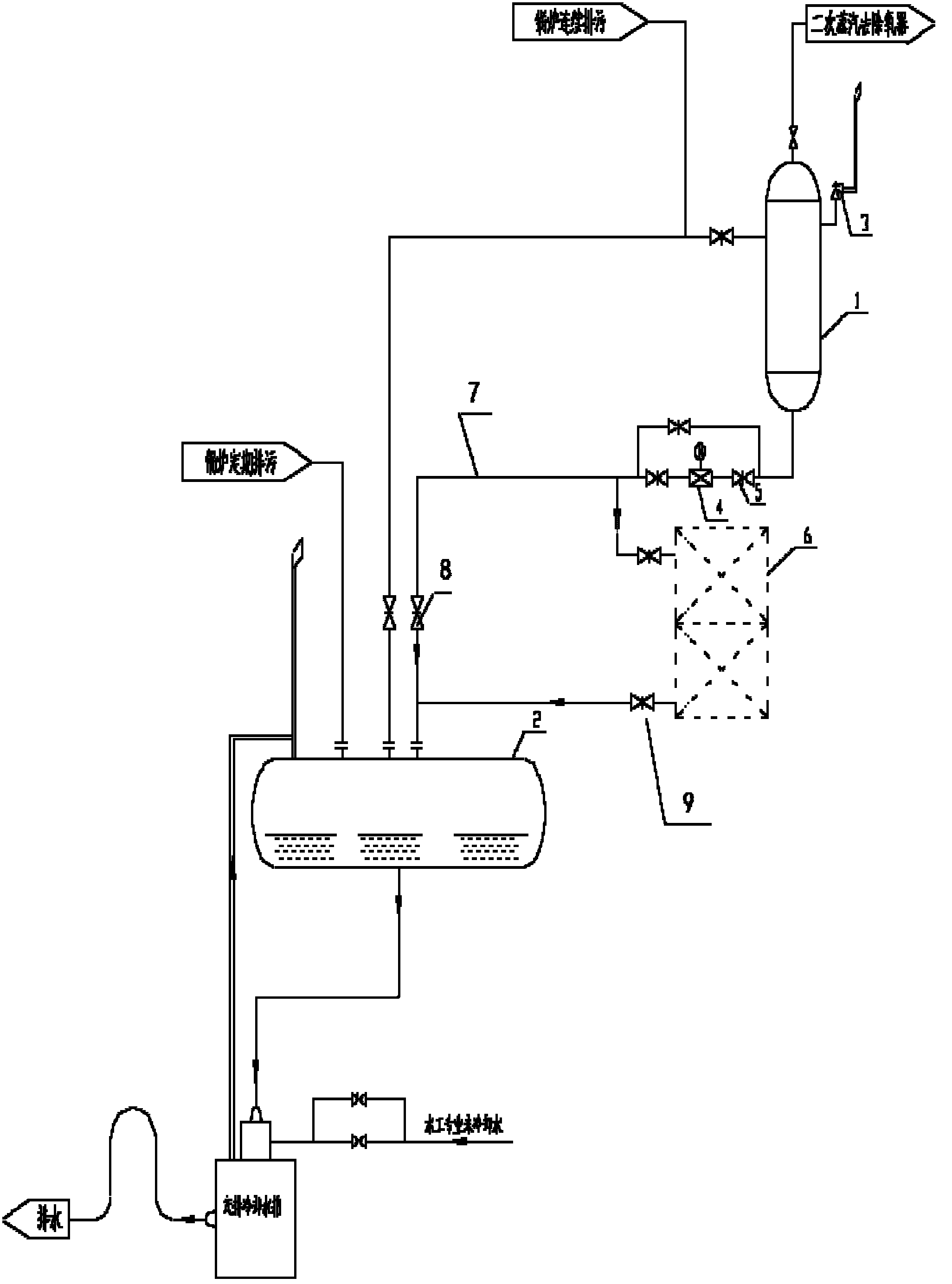

[0021] Boiler row drainage heat recovery system, such as figure 1 , figure 2 Shown in the figure, 1, continuous blowdown expander, 2, regular blowdown expander, 3, safety valve, 4, electric control valve, 5, gate valve 1, 6, drain heater, 7, bypass pipeline, 8, Gate valve III, 9, gate valve II, 10, cleaning port. The drain port at the bottom of the continuous sewage expansion vessel 1 is connected to the regular sewage expansion expansion 2 through a connecting pipeline, the connecting pipeline is provided with an electric regulating valve 4 and a gate valve I 5, the connecting pipeline is provided with a drain heater 6, and the drain heater 6 is provided with a water inlet With the drain, some heat exchange base pipes are established between the water inlet and the drain of the drain heater 6, and the drain heater is located on the cold air passage of the boiler. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com