Shear box device for rock indoor direct shear test

A shear box and rock technology, applied in the field of rock mechanics, can solve problems such as the inability to guarantee the geometric center of the shear load, not shearing, and test failure, etc., and achieve the effects of simple structure, convenient operation, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

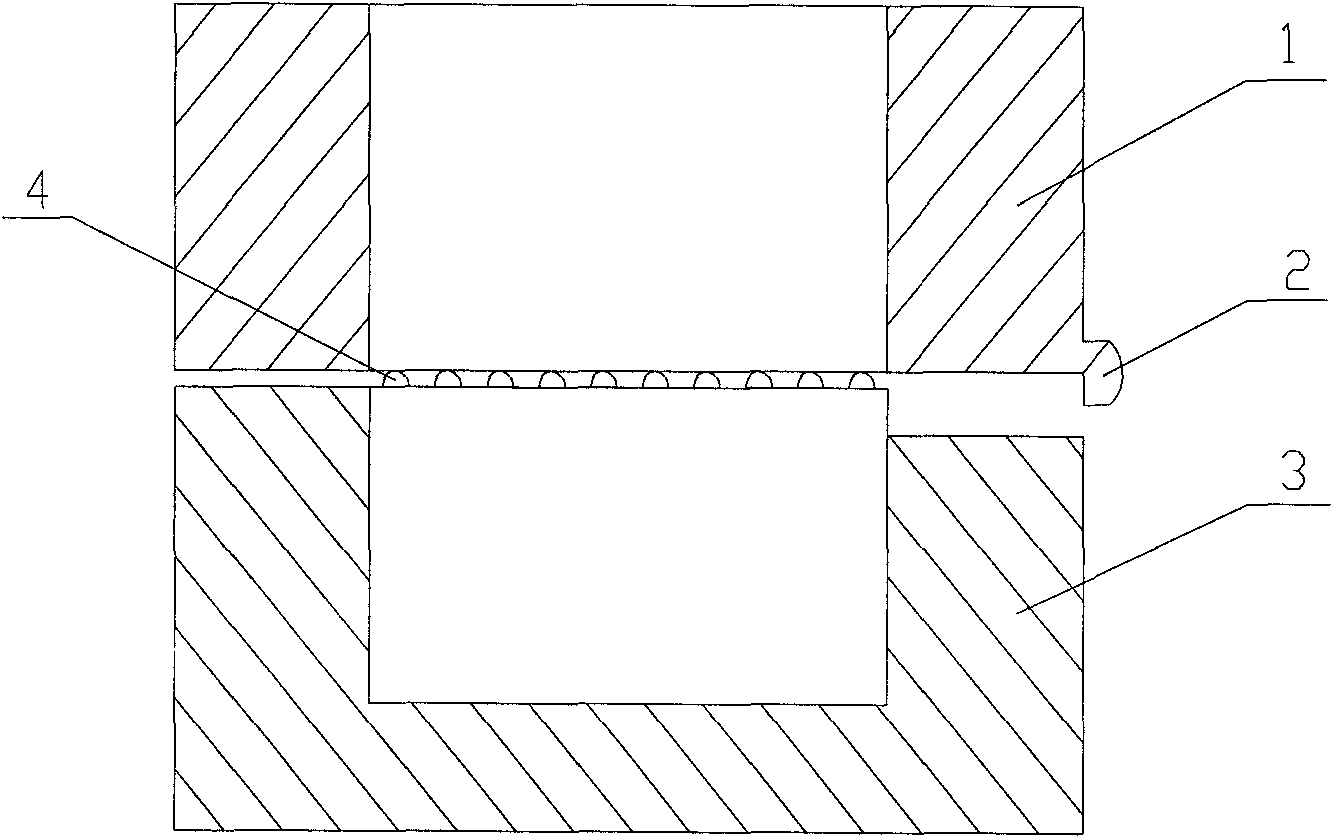

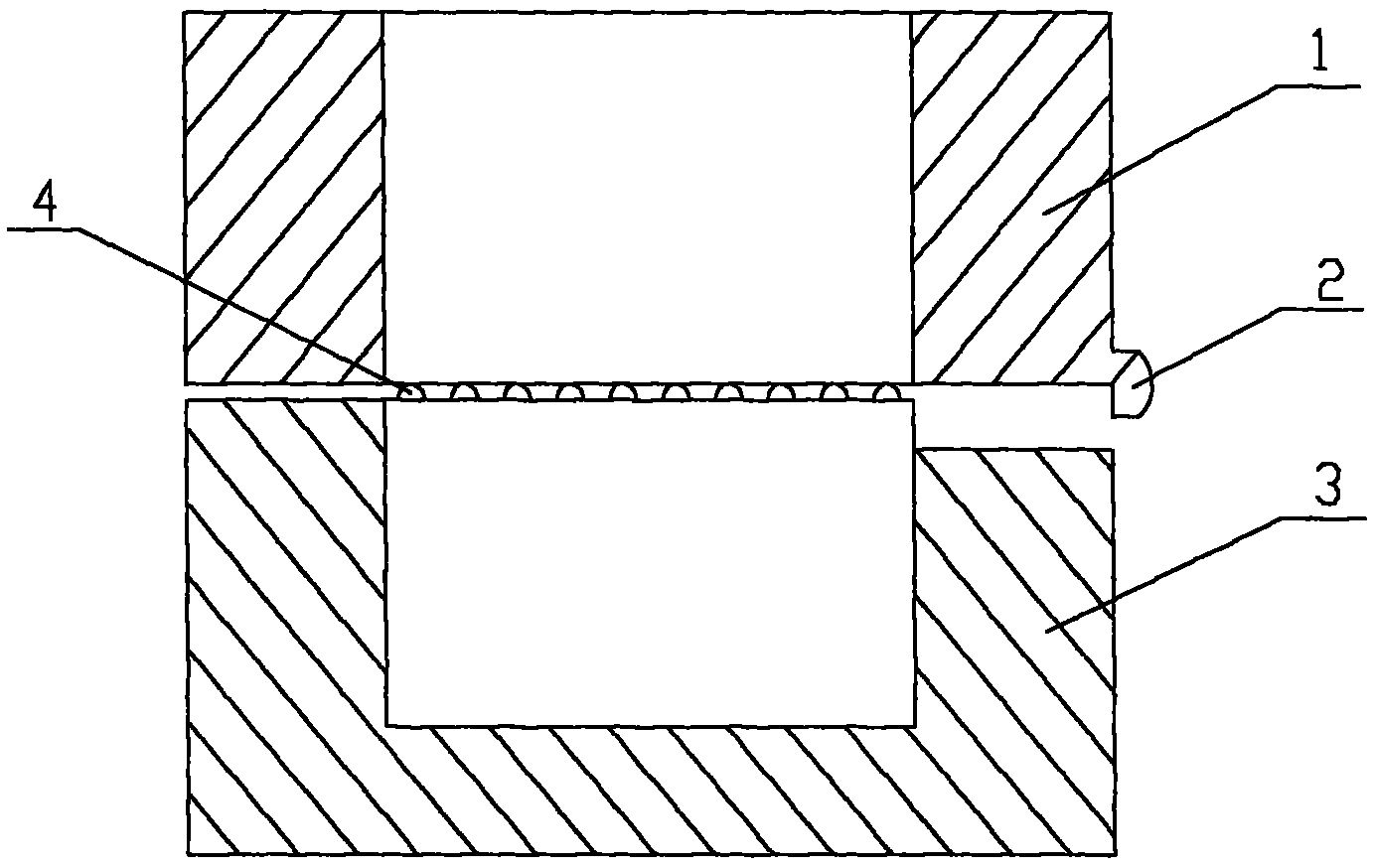

[0011] Below in conjunction with accompanying drawing, the present invention will be further described.

[0012] see Attachment.

[0013] The shear cell device of the direct shear test in the rock chamber includes an upper shear cell 1 and a lower shear cell 3 . The lower shear box 3 is a square box without an upper cover, and the manufacturing material adopts high-strength steel. The front and rear outer walls of box 3 are provided with tension shafts, through which the shear load is applied during the test, grooves are formed on the top of the front and rear walls of the lower shear box 3, and in-line ball rows are respectively embedded in the grooves. 4. The height of the in-line ball row 4 protruding from the top surface of the lower shear box 3 is ≤1 mm, the length of the in-line ball row 4 is consistent with the length of the two inner walls before and after the lower shear box 3, and a pair of in-line balls The rows 4 are parallel to each other to reduce the influence...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com