Integrated coil-biased giant magnetoresistance magneto-dependent sensor

A magnetic sensor and giant magnetoresistance technology, applied in the field of magnetic sensor, can solve the problems of low sensing sensitivity, low product yield, complex manufacturing process, etc., and achieve high sensitivity, high sensitivity, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

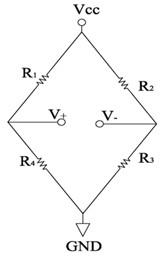

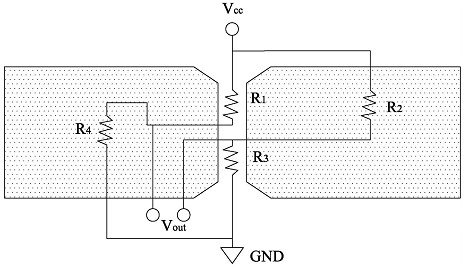

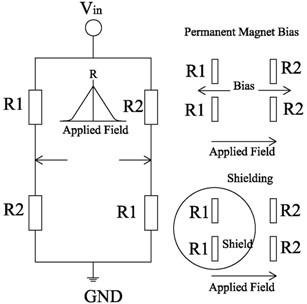

[0026] As shown in Figure 4a, the sensor in this embodiment is composed of a Wheatstone bridge structure composed of four GMR magnetoresistors, an integrated soft magnetic material layer and a pair of integrated bias coils. The integrated soft magnetic layer is a ring structure with a gap made of soft magnetic material, and the GMR magnetosensitive unit forming a Wheatstone bridge is placed in the gap. A pair of GMR magnetoresistors on the bridge arms of the Wheatstone bridge is placed in a gap Gap A of the annular soft magnetic material, and another pair of GMR magnetoresistors is placed in another gap Gap B of the annular soft magnetic material. The two integrated coils can be loaded with current as shown in Figure 4a, so that the magnetic flux generated by the two coils has the same direction in the soft magnetic ring structure. As shown in Figure 4b, the basic working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com