Lead wire structure and displaying panel possessing the lead wire structure

A technology for display panels and leads, applied in nonlinear optics, optics, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

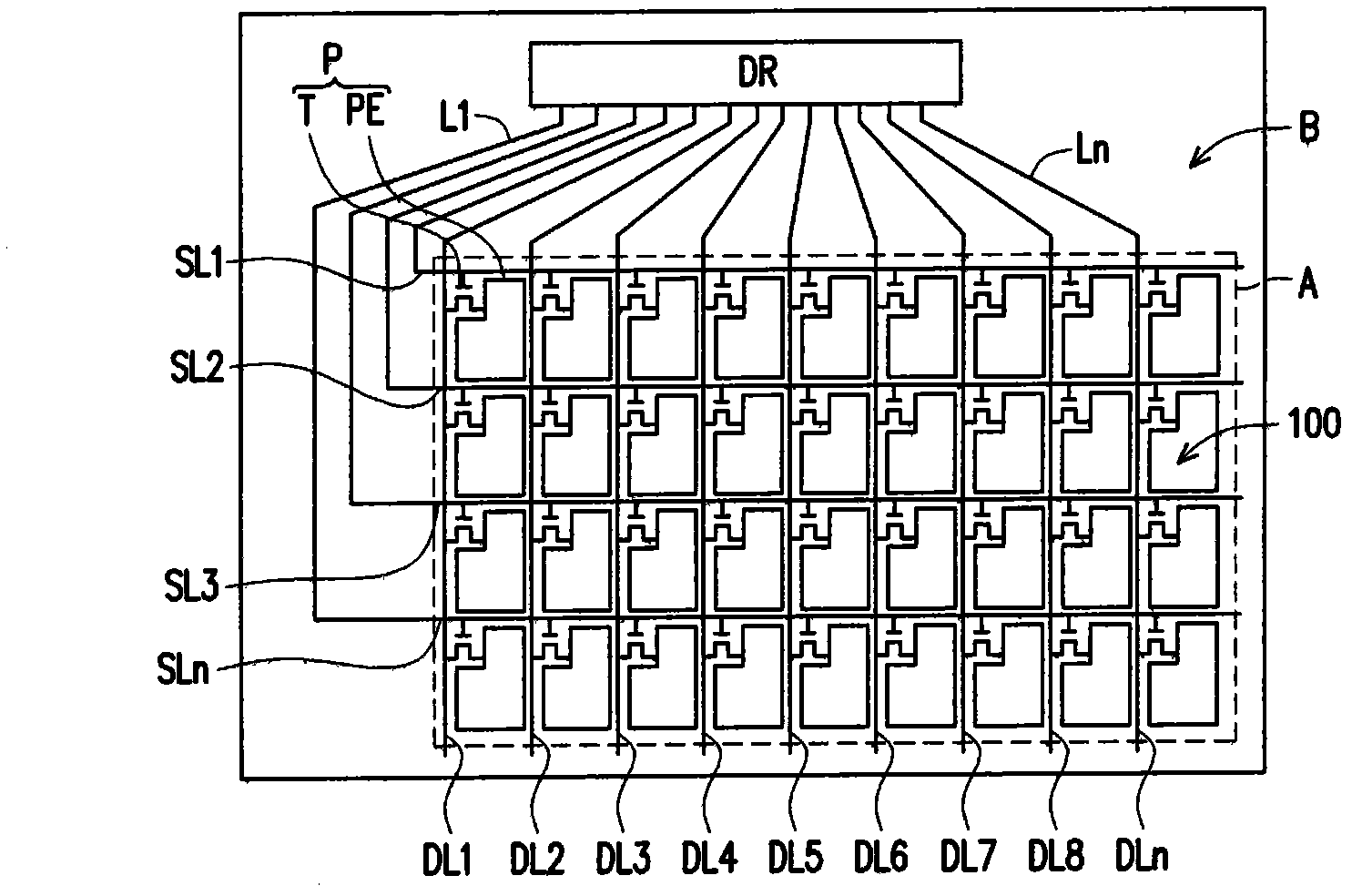

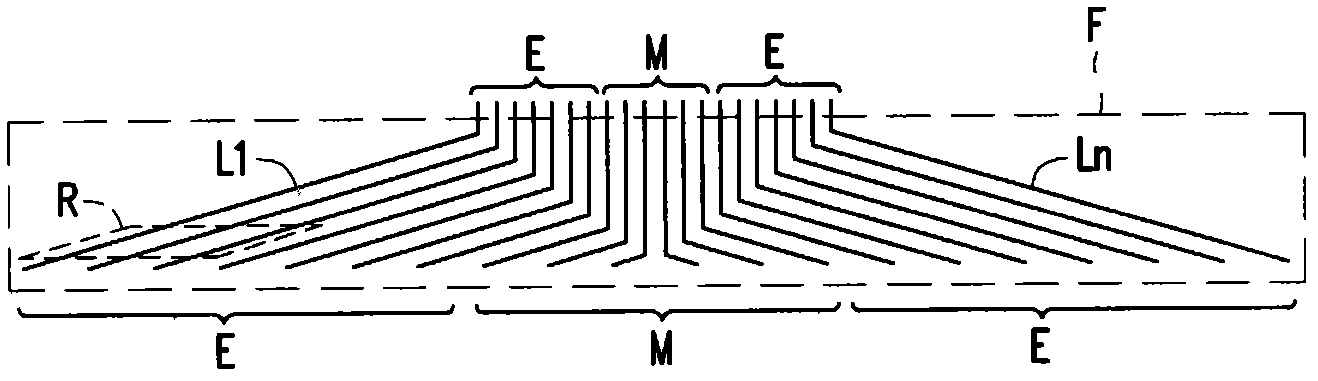

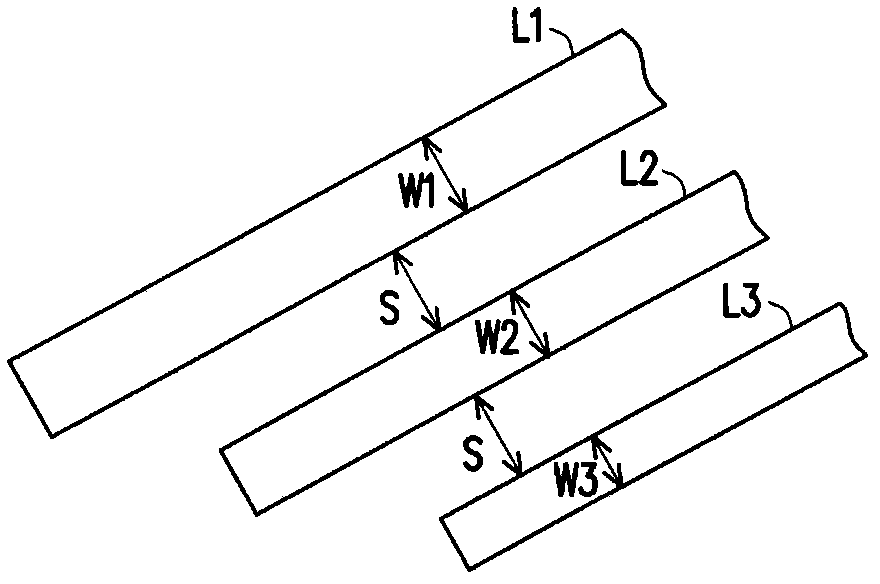

[0021] figure 1 is a schematic top view of a display panel according to an embodiment of the present invention. figure 2 yes figure 1 A schematic diagram of the lead structure of the display panel. Please also refer to figure 1 as well as figure 2 , the display panel of this embodiment includes a display area A and a non-display area B around the display area A. The display panel includes a pixel array 100, at least one driving device DR and a plurality of leads L1-Ln.

[0022] The pixel array 100 is located in the display area A. As shown in FIG. According to this embodiment, the pixel array 100 includes a plurality of scan lines SL1 -SLn, a plurality of data lines DL1 -DLn, and a plurality of pixel structures P. Referring to FIG.

[0023] The scan lines SL1 ˜SLn and the data lines DL1 ˜DLn are disposed across each other, and an insulating layer is interposed between the scan lines SL1 ˜SLn and the data lines DL1 ˜DLn. In other words, the extending direction of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com