Water temperature monitoring method and blockage handling method for generator stator of 1000 megawatt nuclear power plant

A technology for generator stators and nuclear power plants, applied in nuclear power generation, nuclear power plants, nuclear power plant control, etc., can solve problems such as burnout, forced shutdown of stator windings, and easy blockage of stators, so as to avoid damage, ensure power generation efficiency, and solve The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

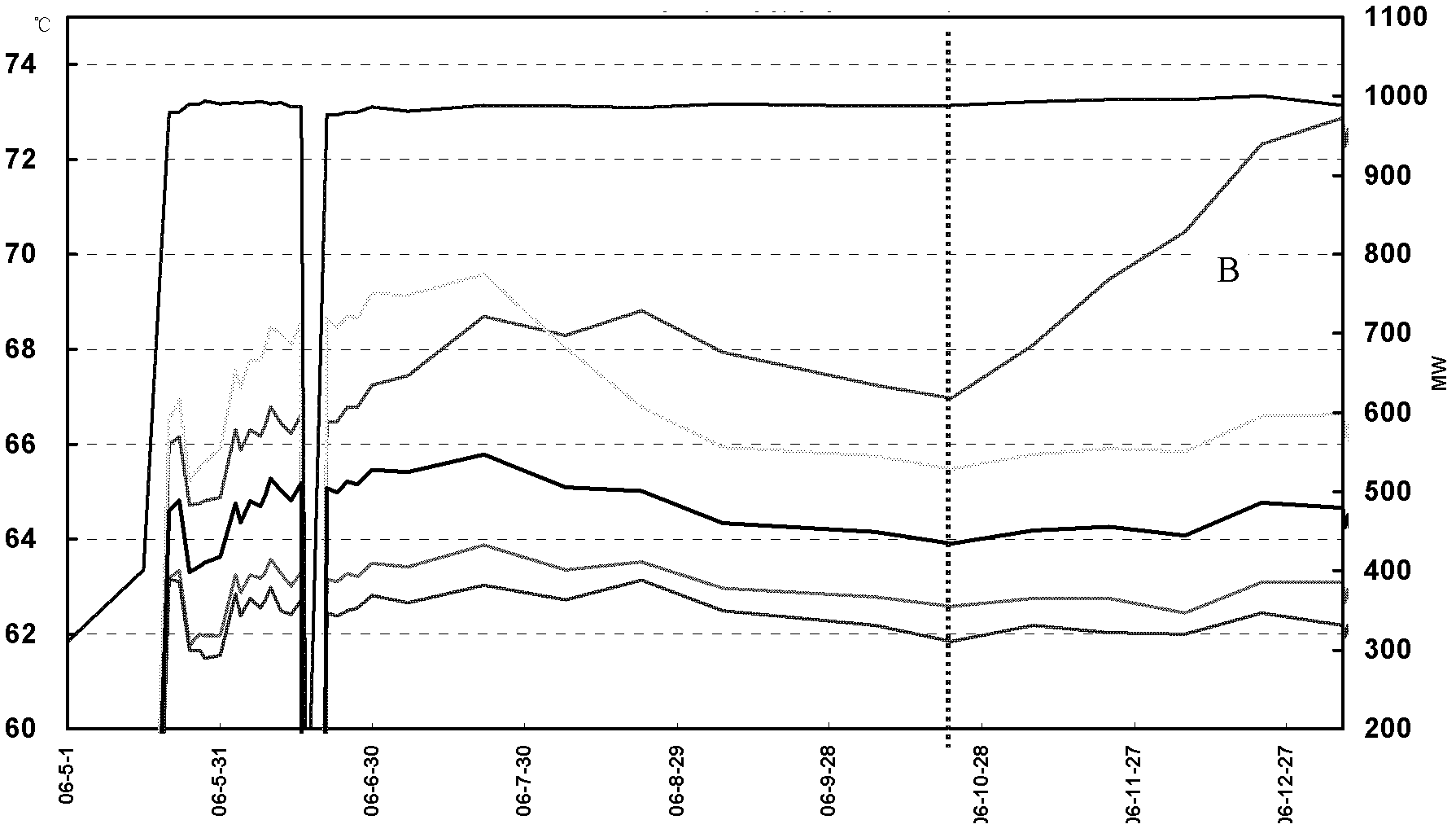

[0043] In a generator of a million-kilowatt nuclear power plant, the material of the stator is copper, and cooling water is passed through the stator to cool the generator; in other words, the copper material of the stator in the above structure is in contact with water for a long time. It should be understood that in a high-purity water system at 25°C, copper can undergo an electrochemical reaction to form copper oxide, cuprous oxide or other copper compounds with low solubility in water. The above-mentioned corrosion products (electrochemical products) are deposited in the water after falling off the surface of the stator. Affected by the amount of deposits and other factors of the generator, if the deposits cannot be discharged in time, blockage may be caused. The specific principle process is briefly described as follows:

[0044]During shutdown, because the generator is in contact with a large amount of oxygen, a large amount of corrosion products (mainly copper oxide) wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com