Feeding method capable of changing bulk material into tubed material

A bulk material and feeding technology, applied in the direction of electrical components, electrical components, etc., can solve the problem of insufficient position accuracy of plug-in electronic components, and achieve the effect of improving position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

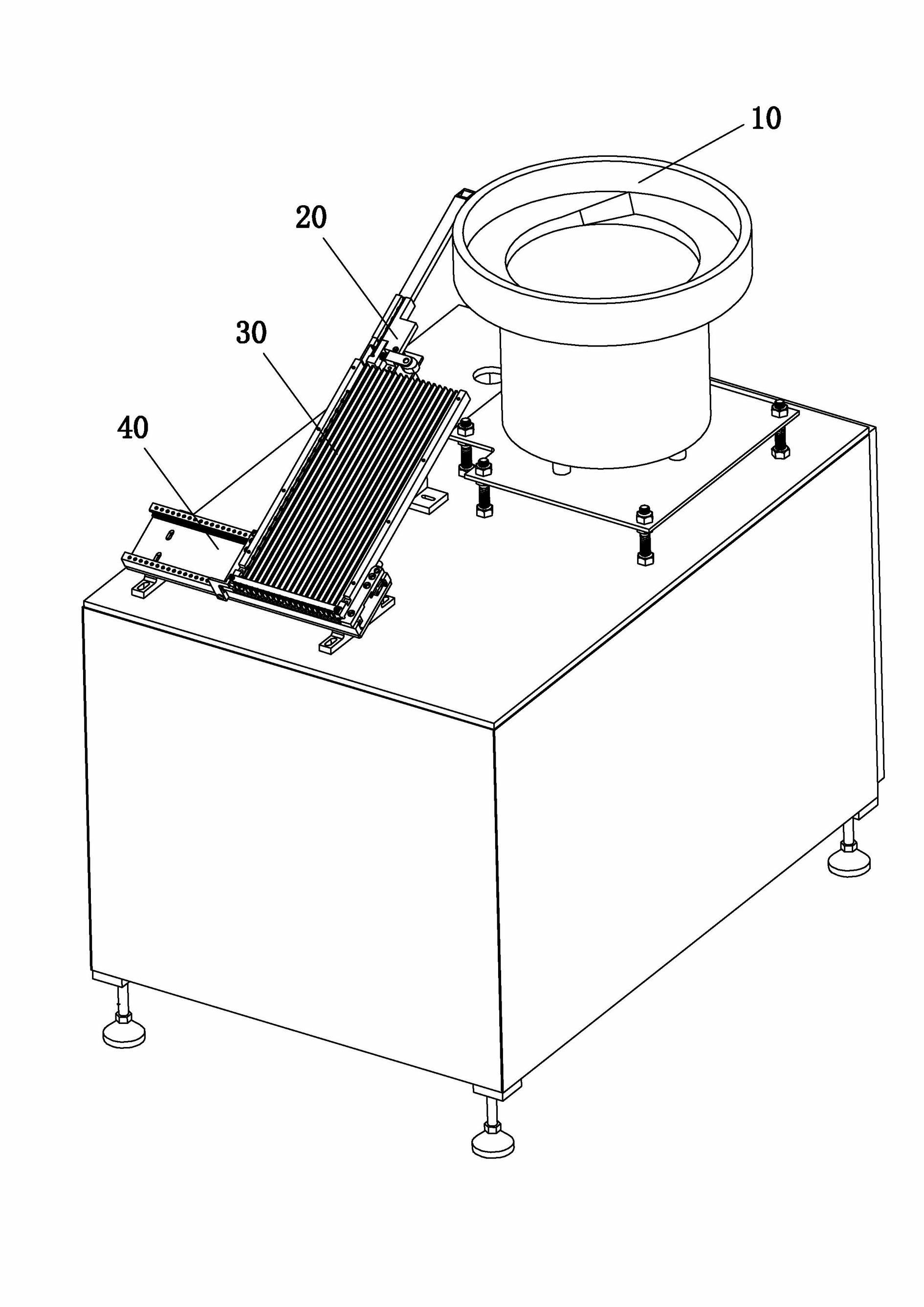

[0054] The feeding method of a kind of bulk material changing tube charging of present embodiment is as follows: Figure 1 to Figure 6 As shown, it includes the following steps:

[0055] Step A: The vibrating plate 10 of the component arrangement packaging machine sequentially arranges the bulk components to the material receiving guide rail;

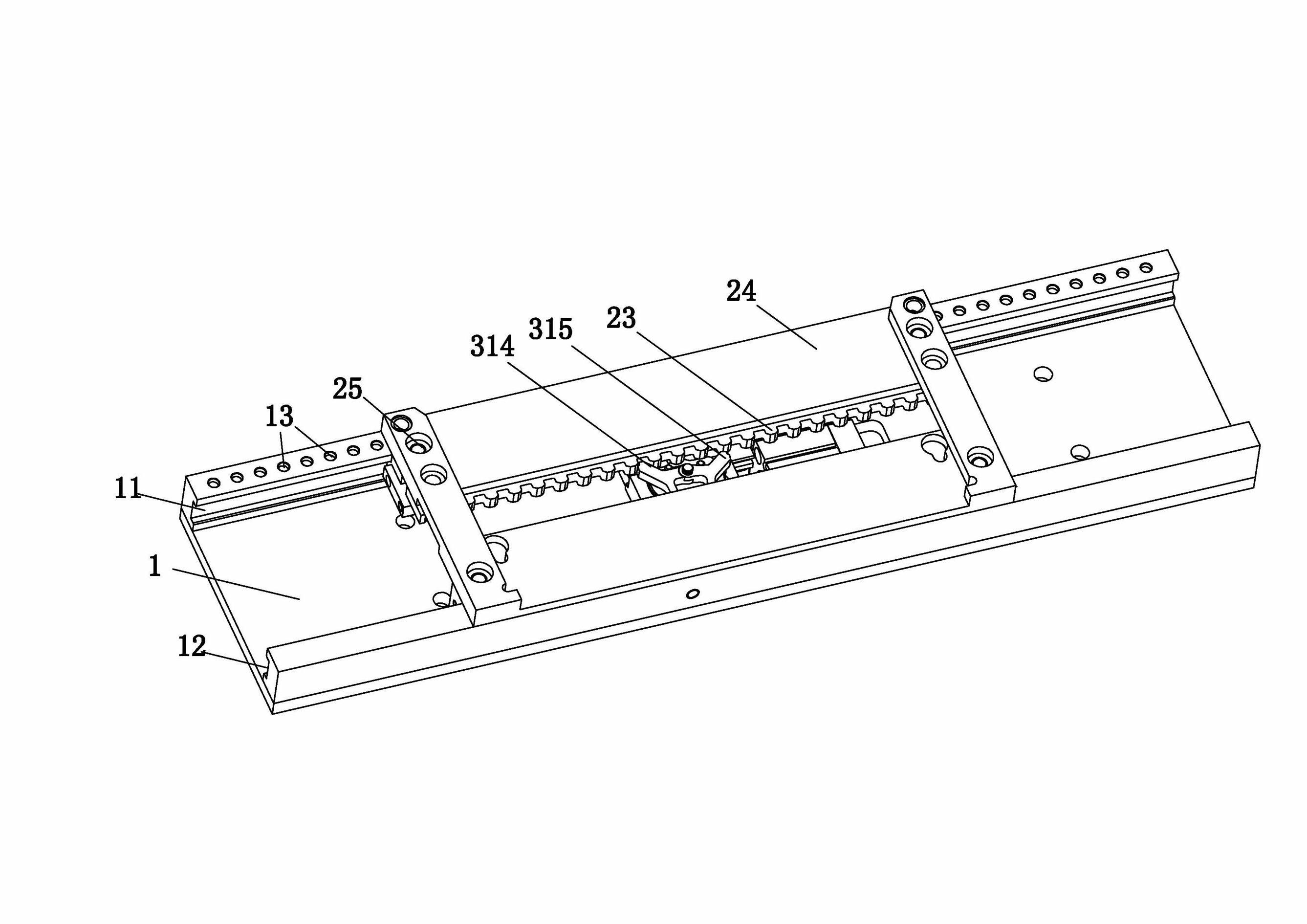

[0056] Step B: Align the material receiving guide rail with one guide rail of the material box 30, and the material pushing and unloading device 20 installs the components on the material receiving guide rail onto the guide rail of the material box 30;

[0057] Step C: The material box 30 is set on the left and right moving mechanism 40 of the charging box. When the guide rail of the material box 30 is filled with components, the left and right moving mechanism 40 of the charging box will move the material box 30 sideways by one guide rail. spacing, so that the pushing and unloading device 20 will install components on the next guide r...

Embodiment 2

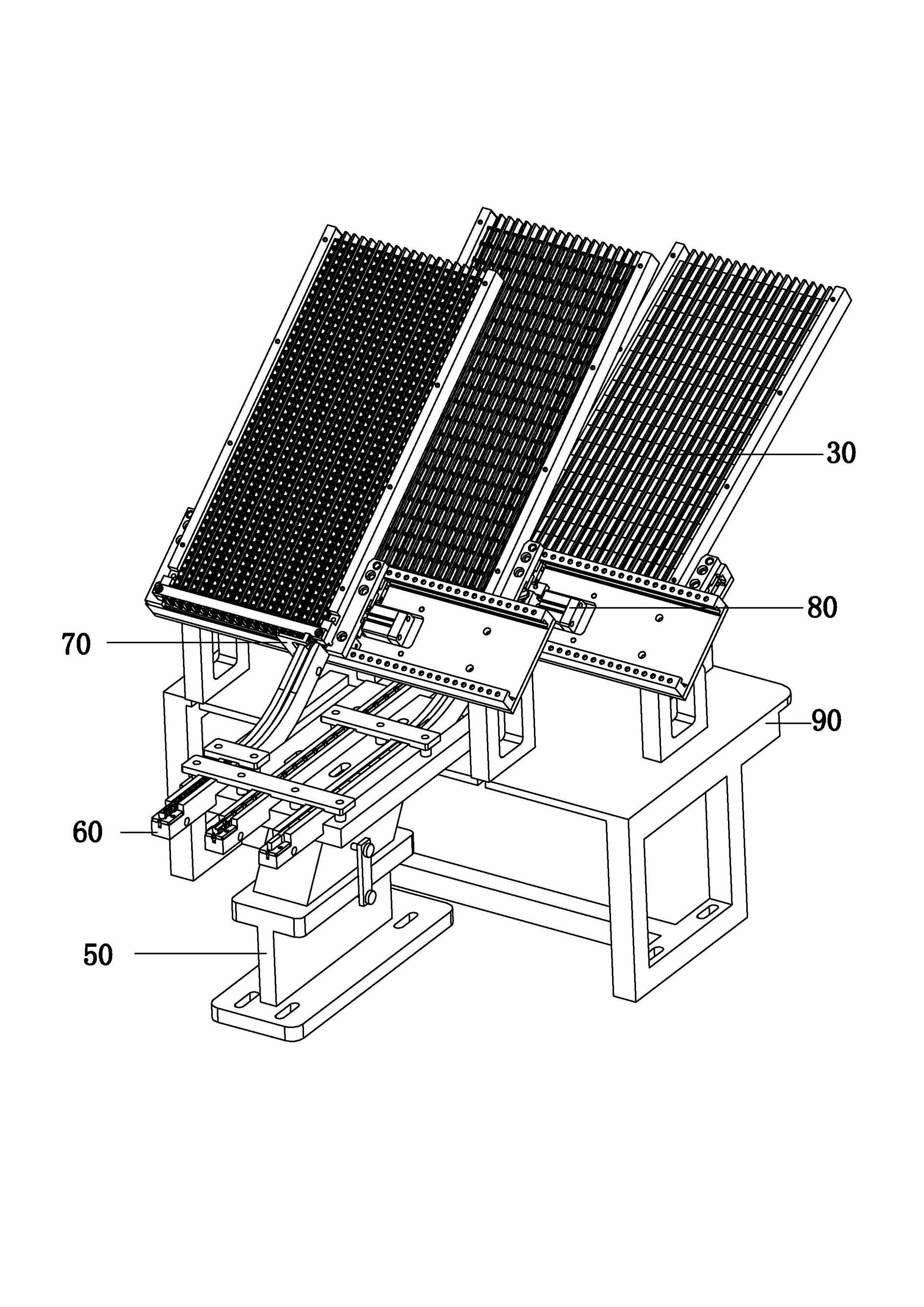

[0064] A method for feeding bulk material into tubes. The other structures of this embodiment are the same as those of Embodiment 1, the difference being that the left and right moving mechanism 40 of the charging box in step C includes a fixed seat, a sliding device and a push device; the fixed seat is provided with a sliding track, the sliding device is movably arranged on the sliding track, and the pushing device pushes the sliding device; the pushing device includes a power device and a left and right reversing switching device, and the power device is connected with the left and right reversing switching device.

[0065] The left and right moving mechanism 40 of the charging box can switch the pushing direction of the pushing device by setting the left and right reversing switching device, and the pushing action of the pushing device to the sliding device can drive the charging box to move back and forth, thereby realizing the movement of the charging box 30 Each rail is l...

Embodiment 3

[0077] A feeding method for changing tube loading of bulk materials. The other structures of this embodiment are the same as those of Embodiment 1, the difference being that: the feeding mechanism in step D includes a linear feeder 50, a charging guide rail 60, and a feeding box. Material block 70, material box 30 and shelf 90, charging guide rail 60 is arranged on linear feeder 50, material box 30 is positioned at the top of charging guide rail 60, the guide rail of material box 30 is docked with charging guide rail 60, and material box discharging block is set On the charging guide rail 60, the material box 30 is arranged on the shelf 90; each guide rail of the material box 30 is provided with a baffle; The moving mechanism 80, the structure and the method of use of the left and right moving mechanism 80 of the blanking box are the same as the left and right moving mechanism 40 of the charging box.

[0078] The feeding method of the feeding mechanism is that the guide rail o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com