Cultured milk with low lactose content and method for manufacturing same

A production method and technology of fermented milk, which is applied in the field of fermented milk, can solve problems such as pH reduction and lactase inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

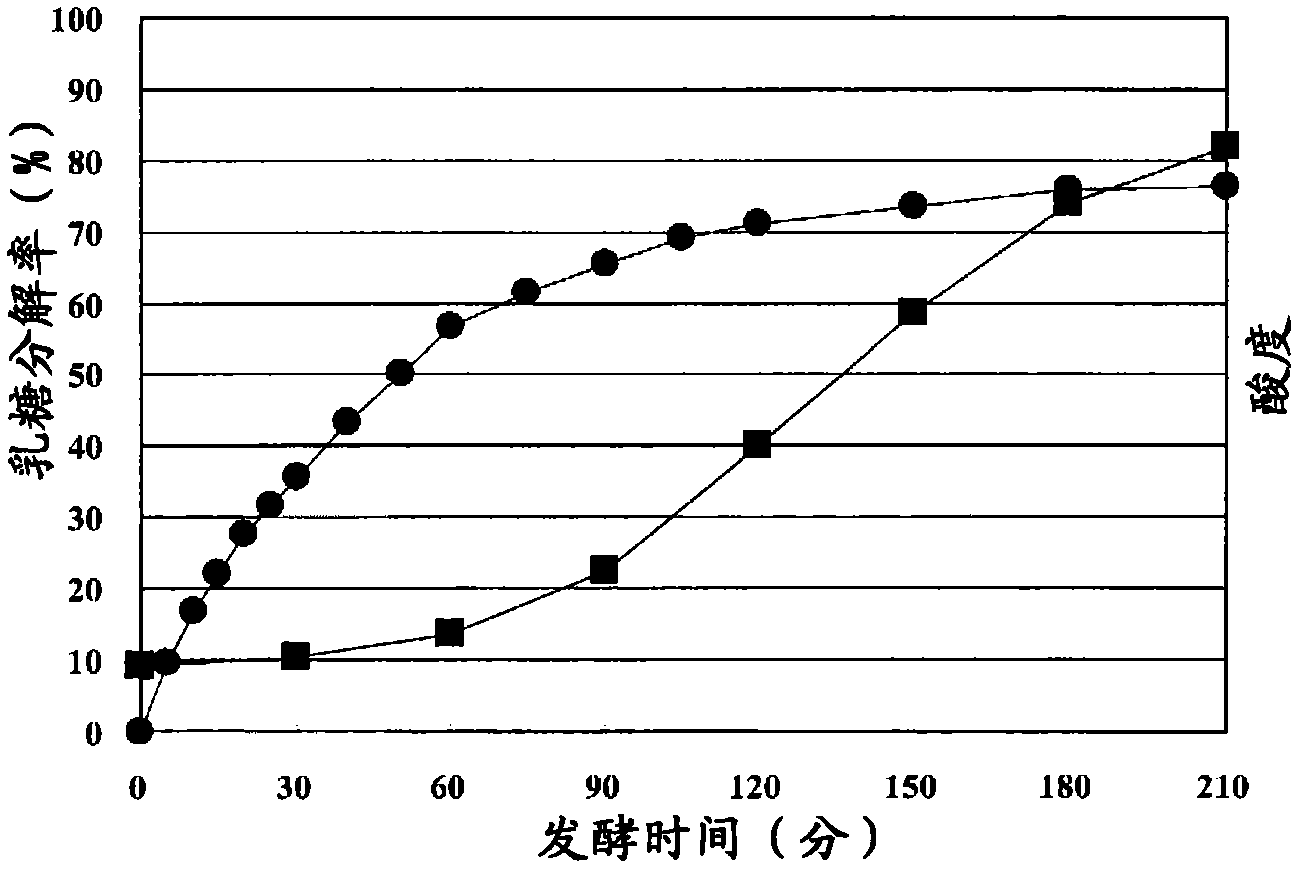

[0036] The present invention will be described more specifically with examples below. Of course, the present invention is not limited to the following examples. Milk (87 parts by weight), skimmed milk powder (2 parts by weight), and tap water (13 parts by weight) were dissolved together to prepare raw material milk. The raw milk was sterilized at 95° C. for 2 minutes. Thereafter, the raw milk was cooled to 40°C. The raw milk is then deoxidized. 0.02% by weight of lactase (enzyme) and 2% by weight of a starter (lactic acid bacteria) for Meiji Bulgaria Yoichi Glut (registered trademark) were added to the deoxygenated raw material milk. Afterwards, the raw material milk was fermented (reacted) at 40° C. to a pH of about 4.7. In this way, fermented milk (Examples 1-4) can be produced.

[0037] Comparative fermented milk (Comparative Examples 1 and 2) was produced in the same manner as in the above-mentioned Examples except that the deoxygenation treatment was not carried out....

Embodiment 5

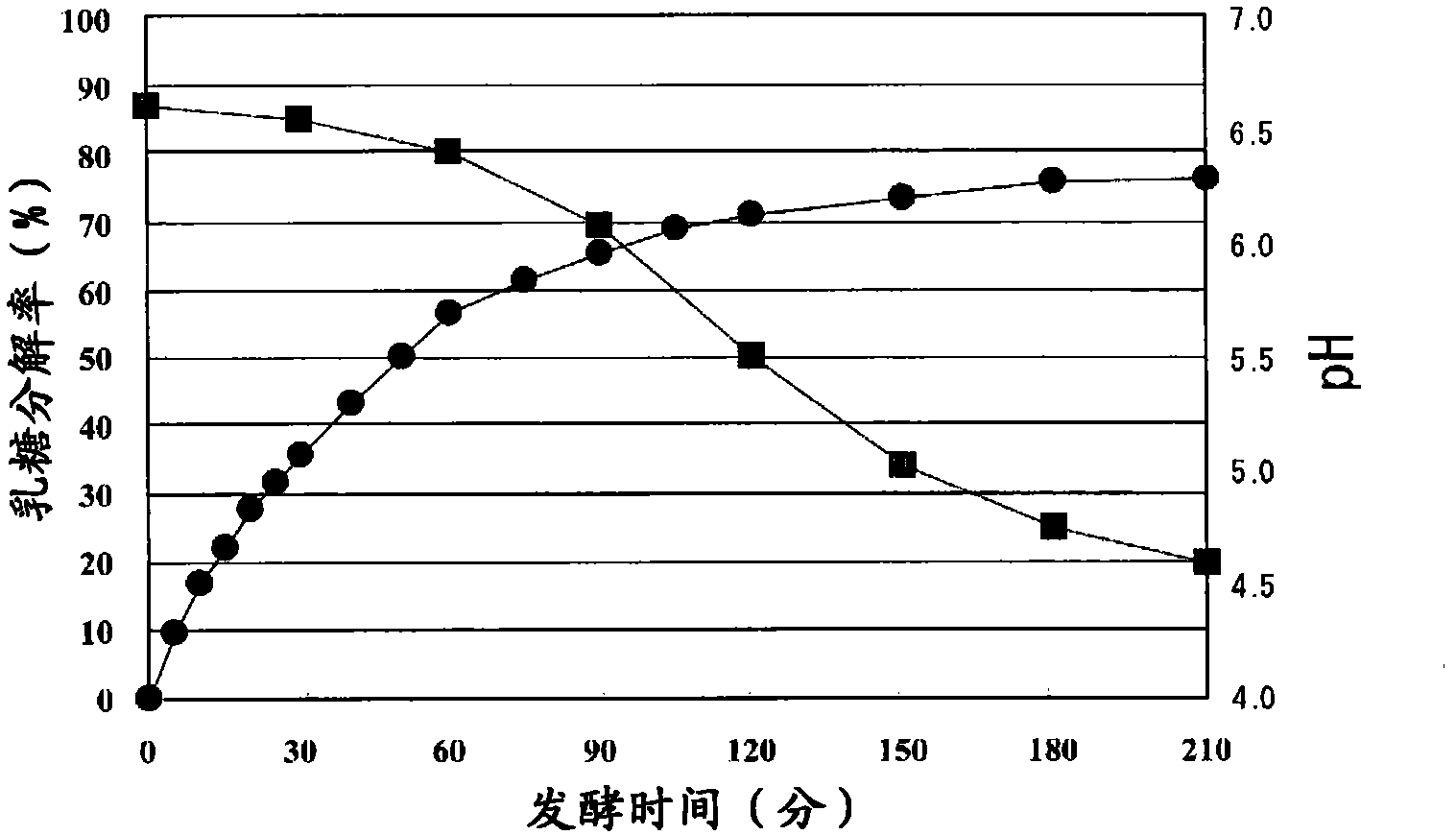

[0050] Embodiment 5: the experiment (best temperature) of adding enzyme and fermenting agent such mode simultaneously

[0051] As the enzyme, GODO-YNL10000 was used. GODO-YNL10000 (10000U / g) contains lactase produced by Kluyveromyces lactis, which is prepared by diluting GODO-YNL 5 times with glycerol. Therefore, GODO-YNL10000's optimal activity temperature, pH value and inactivation conditions are the same as GODO-YNL. In other words, the decomposition reaction by GODO-YNL10000 is optimally carried out in the neutral region of 35-45°C. However, GODO-YNL10000 gradually loses its activity in an environment exceeding 50°C. In addition, GODO-YNL10000 gradually loses its activity in an acidic environment with a pH value below 5. In GODO-YNL10000, glycerin can protect enzymes. Therefore, the heat resistance of GODO-YNL10000 is improved due to the glycerin content. In order to test the heat resistance of GODO-YNL10000, GODO-YNL10000 was heated at the temperature shown in Tabl...

Embodiment 6

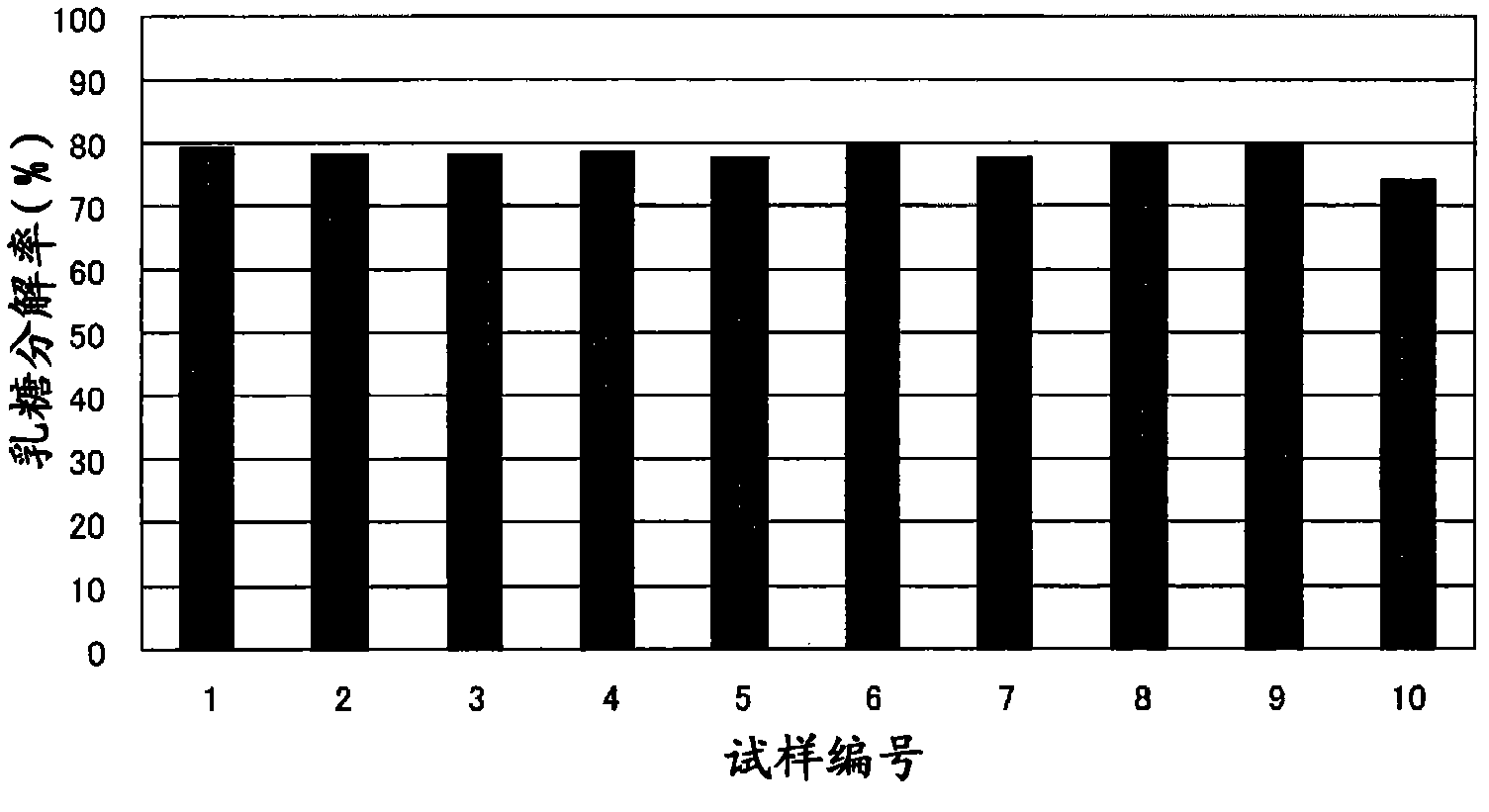

[0056] Embodiment 6: the experiment (for adding amount) to enzyme, fermenting agent adding such mode simultaneously

[0057] Next, the effect of the amount of enzyme added was studied. GODO-YNL10000 (lactase) was kept at 38°C for 1 hour, and then the GODO-YNL10000 was added to the yogurt mixture at the same time as the addition ratio shown in Figure 4. The same method as in Example 4 was used to make fermented milk. The result is shown in Figure 4. In the table, F-kit represents the measurement result by F-kit, and HPLC represents the measurement result by high performance liquid chromatography.

[0058] Table 4 Research on heat resistance of GODO-YNL10000

[0059]

[0060] From the results in Table 4, it can be seen that a good lactose decomposition rate can be obtained even if only about 0.05% by weight of lactase is added. In addition, when lactase is added in an amount of 0.1% by weight or more, a high decomposition rate of lactose can be obtained. That is, the q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com