Method and system for separating electron components in waste circuit board in electromagnetic induction

A technology of electronic components and waste circuit boards, applied in environmental protection equipment and application fields, can solve problems such as environmental pollution, toxic gas leakage, cumbersome loading and unloading, etc., and achieve high separation efficiency, fast processing speed, and no environmental damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described below according to accompanying drawing.

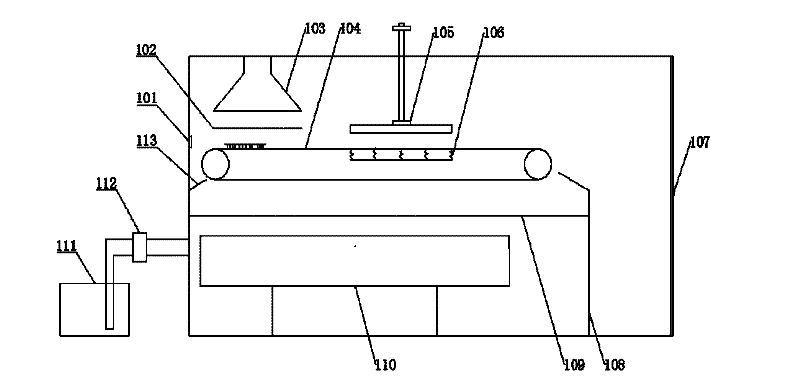

[0035] figure 1 It is a schematic diagram of the overall structure of the equipment. The box shell is composed of two layers of non-magnetic metal plates with thermal insulation material glass fiber cotton in the middle. The box is connected and optionally swivel, and the lower end can be closed under the action of gravity. One side of the upper end of the box body is an air inlet 103, and the blower is on the outside of the box body, and is connected to the air inlet 103 on the top of the shell through a pipe. For heating, the heating temperature of the heating electric wire mesh is adjustable, and the adjustment range is 150°C to 300°C. An impact mechanism 105 is arranged in the middle part of the upper end of the box body, and the impact mechanism is driven by other external power mechanisms. The door on the other side of the box can be opened and closed, which is convenient for the asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com