Automatic assembly device of round-head dimming bolt

An automatic assembly device and screw technology, which is applied in the direction of workpiece clamping device, metal processing, metal processing equipment, etc., can solve the problems of low product qualification rate, low assembly efficiency, high labor intensity, etc., and achieve a reasonable and compact structure, The effect of improving assembly efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

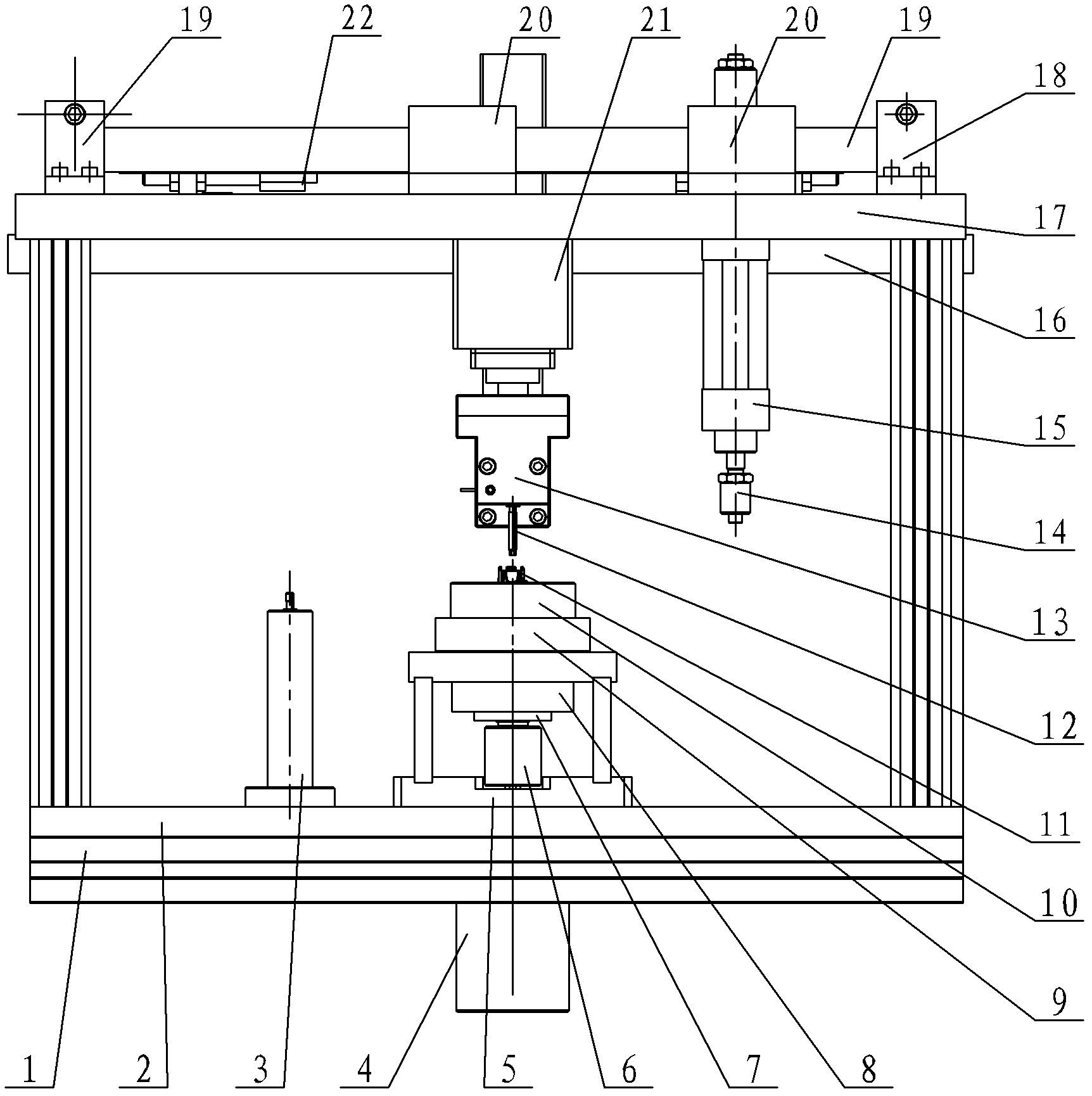

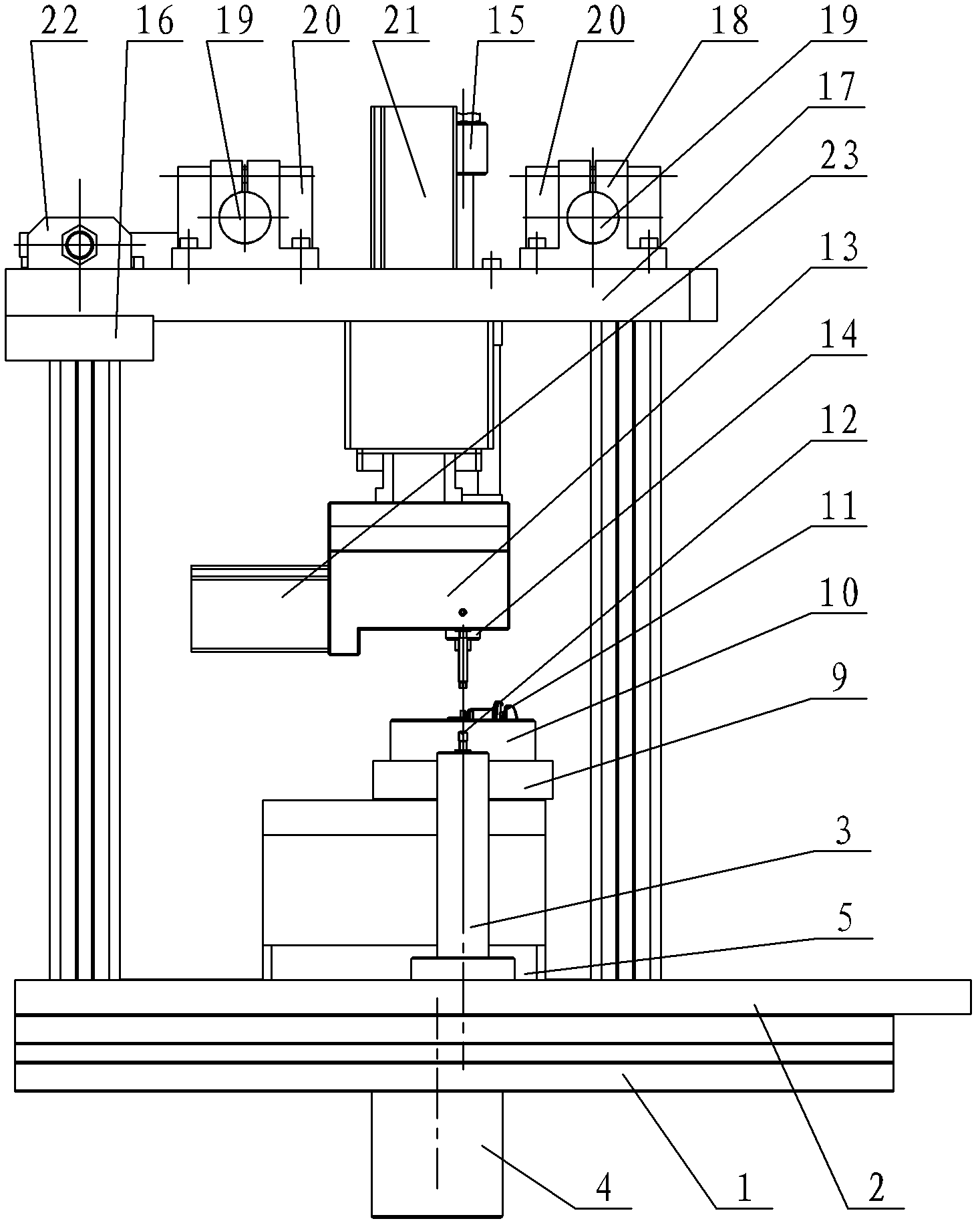

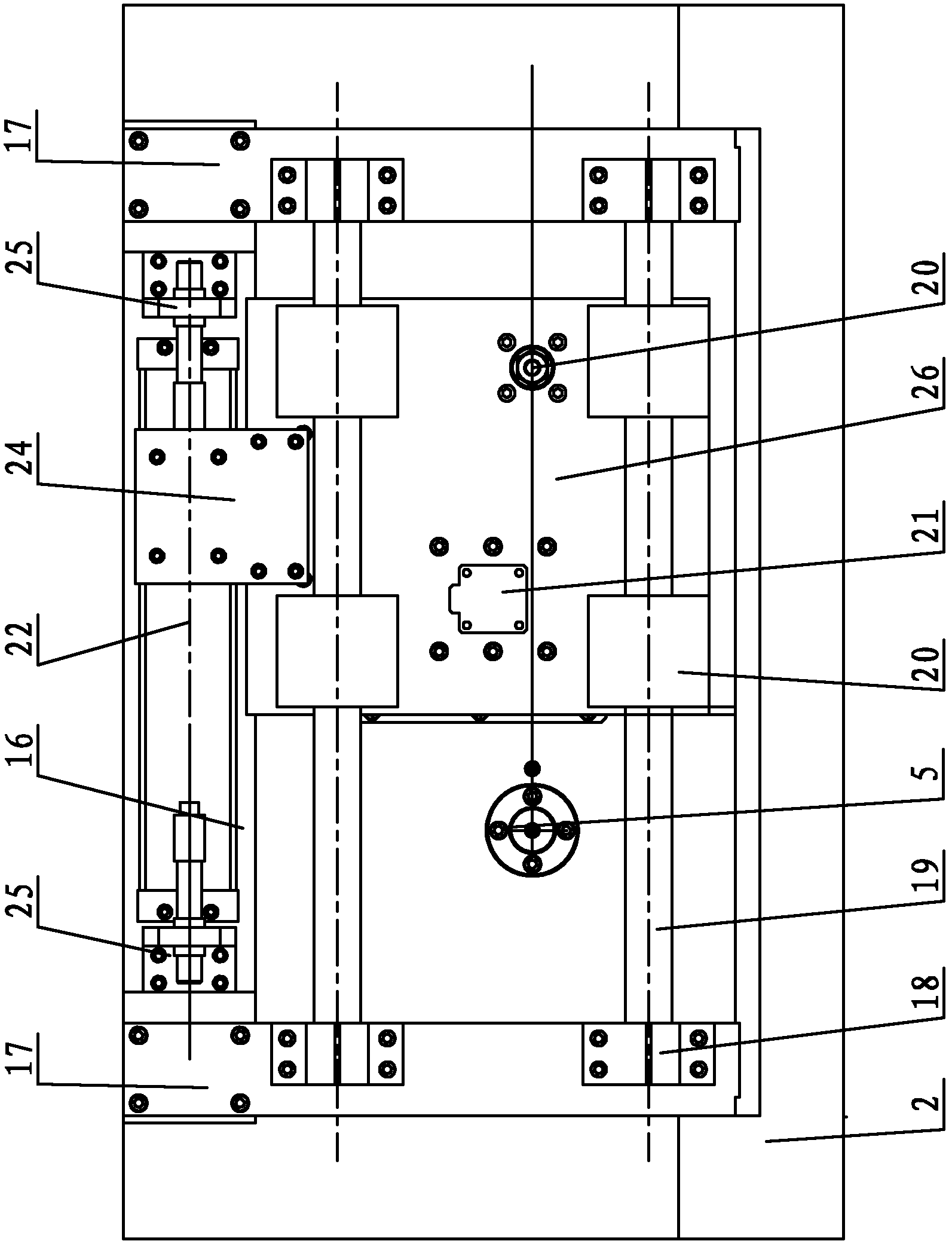

[0019] See figure 1 , 2 As shown, the automatic assembly device of the round head dimming screw of the present invention includes a frame 1, a bottom plate 2 installed on the lower part of the frame 1 and a top plate 17 on the upper part, as well as a screw picking mechanism, a nut seat mechanism, a nut pressing mechanism and a lateral mobile agency. See Figure 1~3 As shown, the frame 1 of the present invention is composed of columns and beams to form a frame structure, and has good mechanical strength. The frame 1 can be installed on the workbench for easy operation. The bottom plate 2 and the top plate 17 are respectively installed by fasteners. On frame 1, in order to reduce the weight of the present invention, this top board 17 can adopt split structure, and top board 17 is made of two boards, and two boards are installed on the top of column respectively.

[0020] As shown in 1 to 4, the screw picking mechanism of the present invention includes a screw seat 3 install...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap