Method for producing a multilayer system and corresponding multilayer system

A corresponding, structured technology, applied in the direction of chemical instruments and methods, lamination, application, etc., to achieve the effect of shortening time, improving flexibility, reliable and durable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

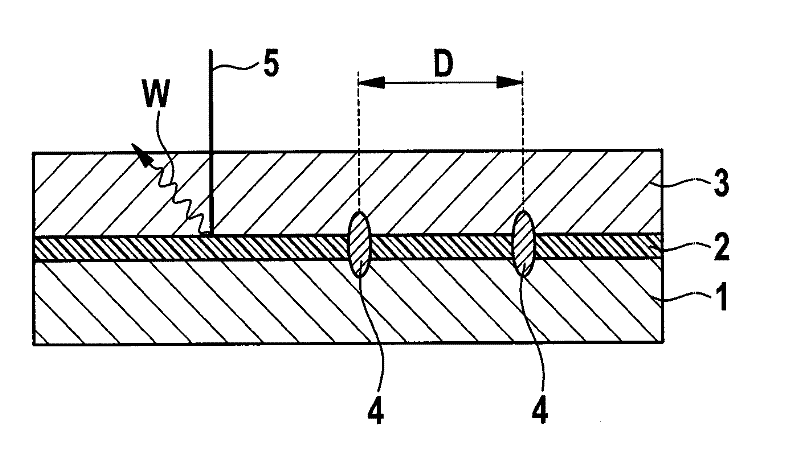

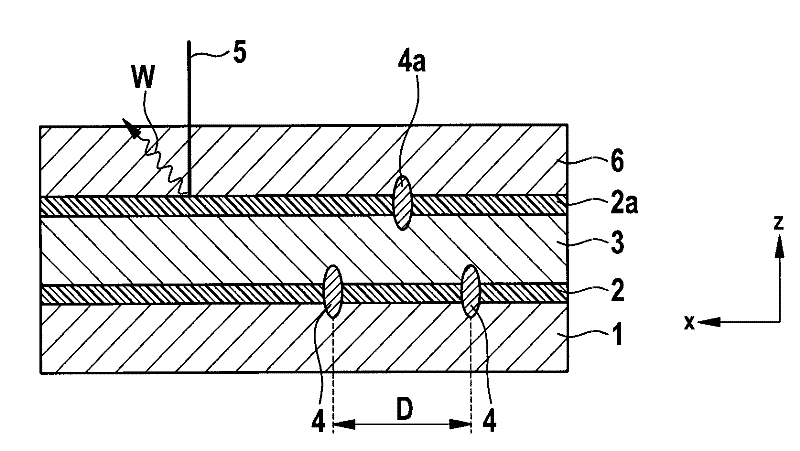

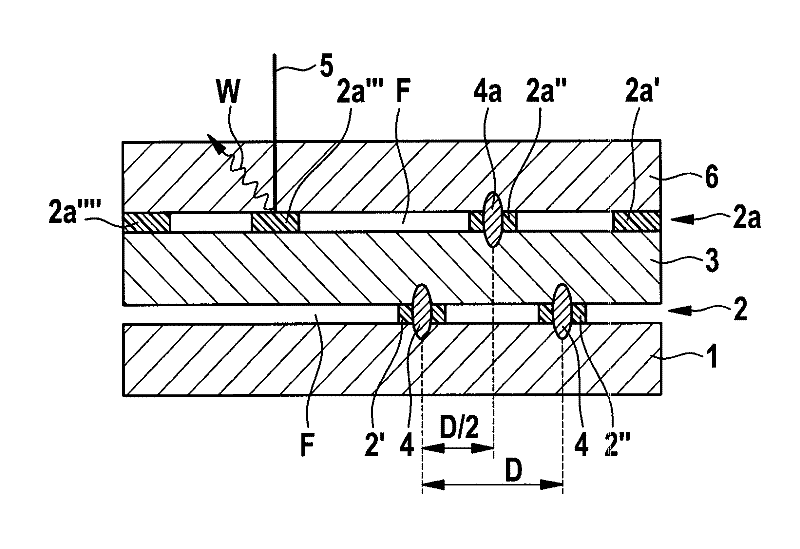

[0022] Unless otherwise stated, identical reference numbers in the figures designate identical or functionally identical elements.

[0023] FIG. 1 shows the production steps of the method according to a first embodiment of the invention. Reference numeral 1 in FIG. 1 designates a first joining element in the form of a transparent thermoplastic. The second joining element 3 is likewise designed in the form of a transparent thermoplastic. An absorbent thermoplastic elastomer film 2 is arranged as a compensating element between the two joining elements 1 , 3 . The two joining elements 1 , 3 are here configured in the form of plates.

[0024] according to Figure 1a , the structure from bottom to top is as follows: A thermoplastic elastomer film is arranged on the first joining element 1 . The thermoplastic elastomer film is here in the best possible mechanical contact with the surface of the joining element 1 . A transparent second joining element 3 is also arranged on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com