Pallet loading and unloading device

A rack device and pallet technology, which is used in transportation and packaging, conveyor objects, stacking of objects, etc., can solve the problems of low labor efficiency, high labor intensity, slow placement or unloading, etc., to improve labor efficiency. Efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

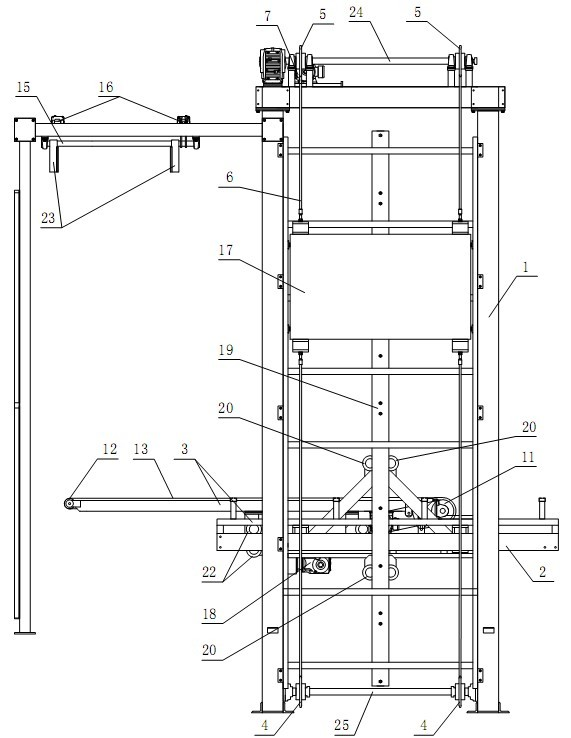

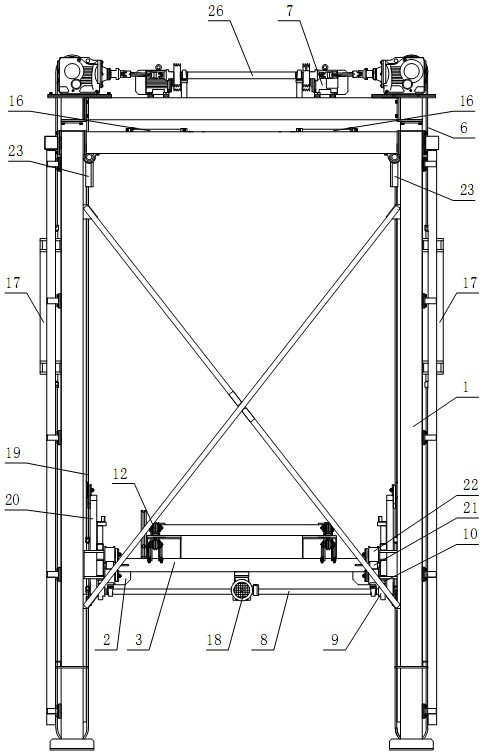

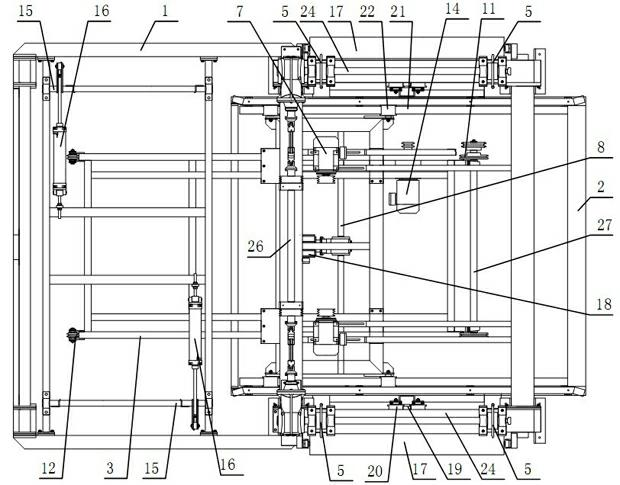

[0017] Such as figure 1 , figure 2 with image 3 The pallet up and down racking device shown, for the convenience of description, takes the traveling direction of the trolley as the horizontal direction, and the device includes a frame 1, and a drying cart positioning device is installed on the lateral side of the frame 1, and the drying cart positioning device includes a rotating installation. Two positioning shafts 15 that are arranged oppositely on the frame 1, the positioning shafts 15 are arranged horizontally, each positioning shaft 15 is fixedly equipped with two clamping arms 23, and two clamping arms 23 that drive the two positioning shafts 15 to rotate are installed on the frame 1 respectively. Drive cylinder 16, the two ends of positioning shaft 15 are also fixedly equipped with swing arms, the piston rod of the above-mentioned drive cylinder 16 is hinged on the swing arm, the drying car will enter the side of the device longitudinally, start drive cylinder 16, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com